• 特约评述 •

生物法回收电池关键金属研究进展

朱思羽1, 赵炫烨2, 虞雯静2, 曹竞天2, 刘思慧3, 钱文达3, 贾海洋2

- 1.北京理工大学医学技术学院,北京 100081

2.北京理工大学化学与化工学院,北京 102488

3.北京理工大学生命学院,北京 100081

-

收稿日期:2025-03-24修回日期:2025-06-23出版日期:2025-06-24 -

通讯作者:贾海洋 -

作者简介:朱思羽 (2004—),女,本科生。研究方向为蛋白质组学、代谢组学和蛋白质交联和合成生物学相关,所在BIT-China团队荣获2024年合成生物学创新赛金奖、2024年iGEM金奖和三项单项奖提名。 E-mail:1120222466@bit.edu.cn贾海洋 (1988—),男,教授,博士生导师,研究方向为合成生物学分子调控工具的开发、人工细胞等仿生系统的构建与应用、新型人工细胞代谢工厂设计与工程应用、基于生物大分子的3D打印微型机器人的设计与构建、新型抗体开发与高通量抗体筛选技术的研发等。E-mail:haiyangjia@bit.edu.cn -

基金资助:科技部, 国家重点研发计划“合成生物学”重点专项-课题(2023YFA0914803)

Advances in Biological Recovery of Key Battery Metals

ZHU Siyu1, ZHAO Xuanye2, YU Wenjing2, CAO Jingtian2, LIU Sihui3, QIAN Wenda3, JIA Haiyang2

- 1.Beijing Institute of Technology,School of Medical Technology,Beijing,100081,China

2.Beijing Institute of Technology,School of chemistry and chemical engineering,Beijing,102488,China

3.Beijing Institute of Technology,School of life science,Beijing,100081,China

-

Received:2025-03-24Revised:2025-06-23Online:2025-06-24 -

Contact:JIA Haiyang

摘要:

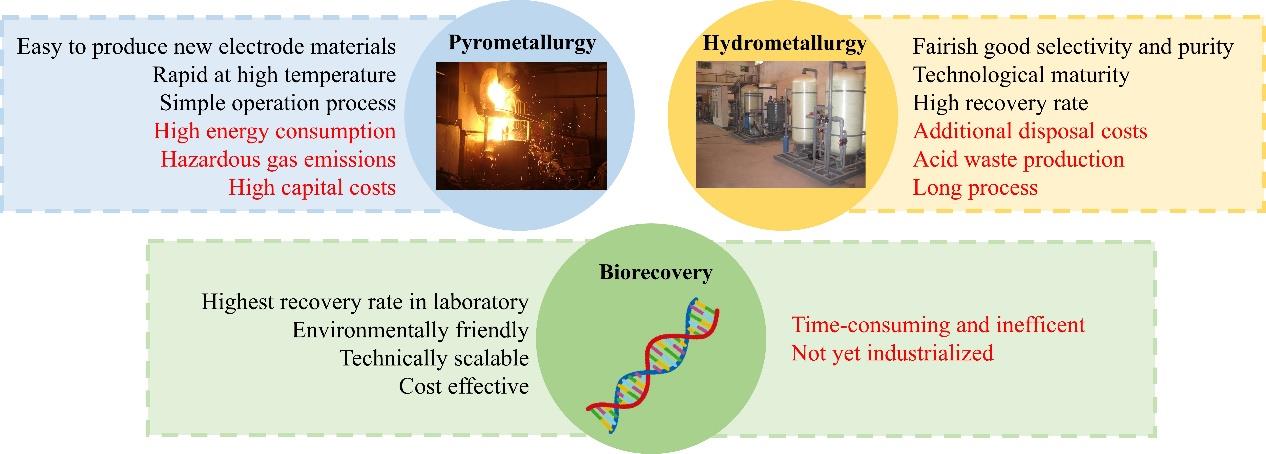

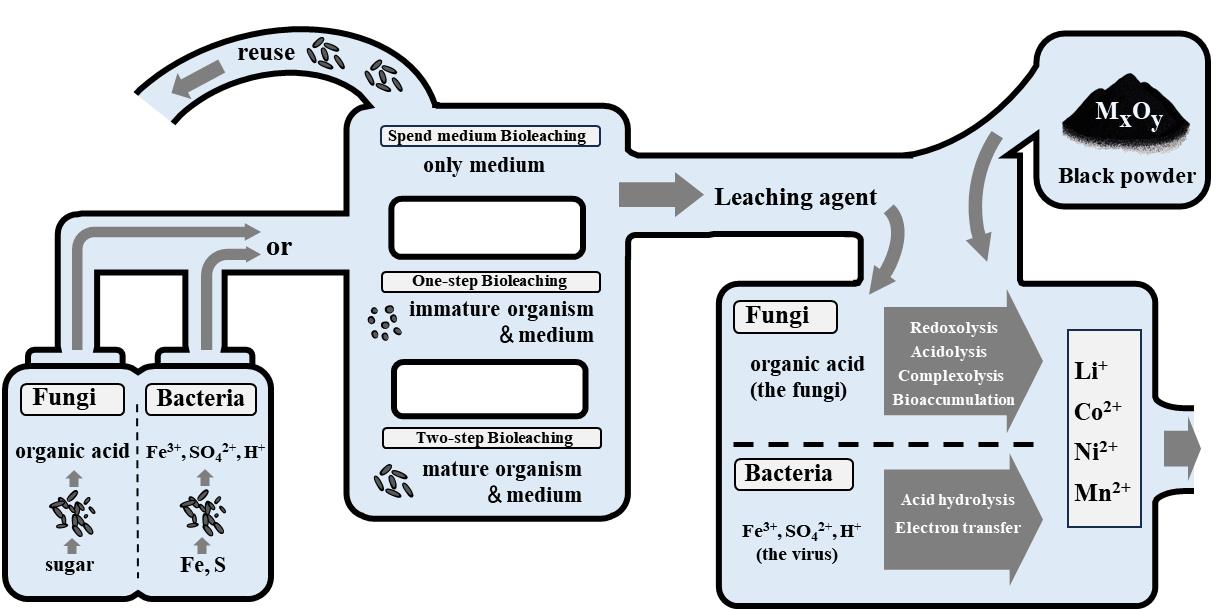

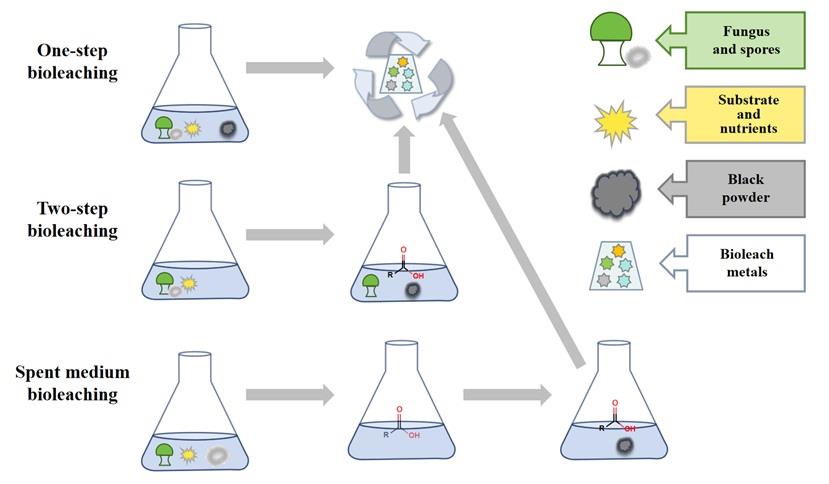

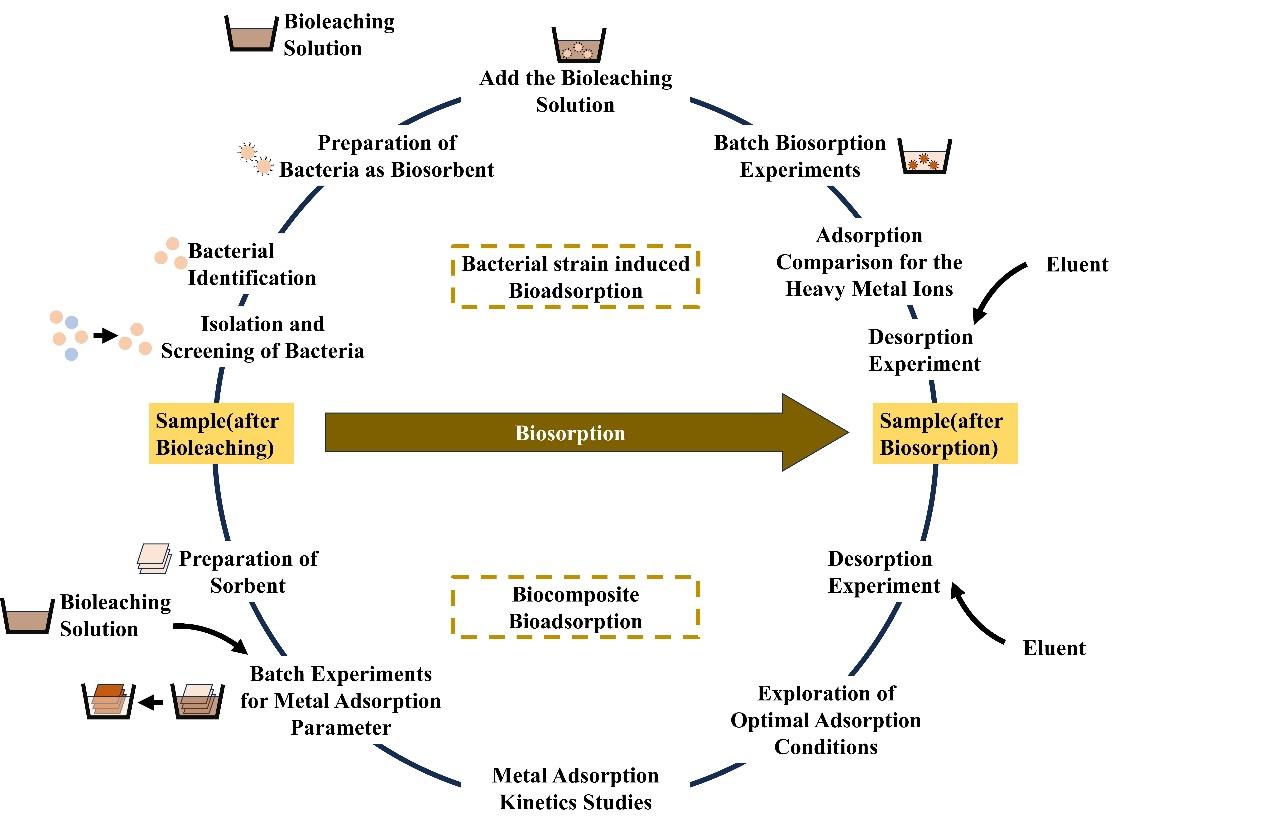

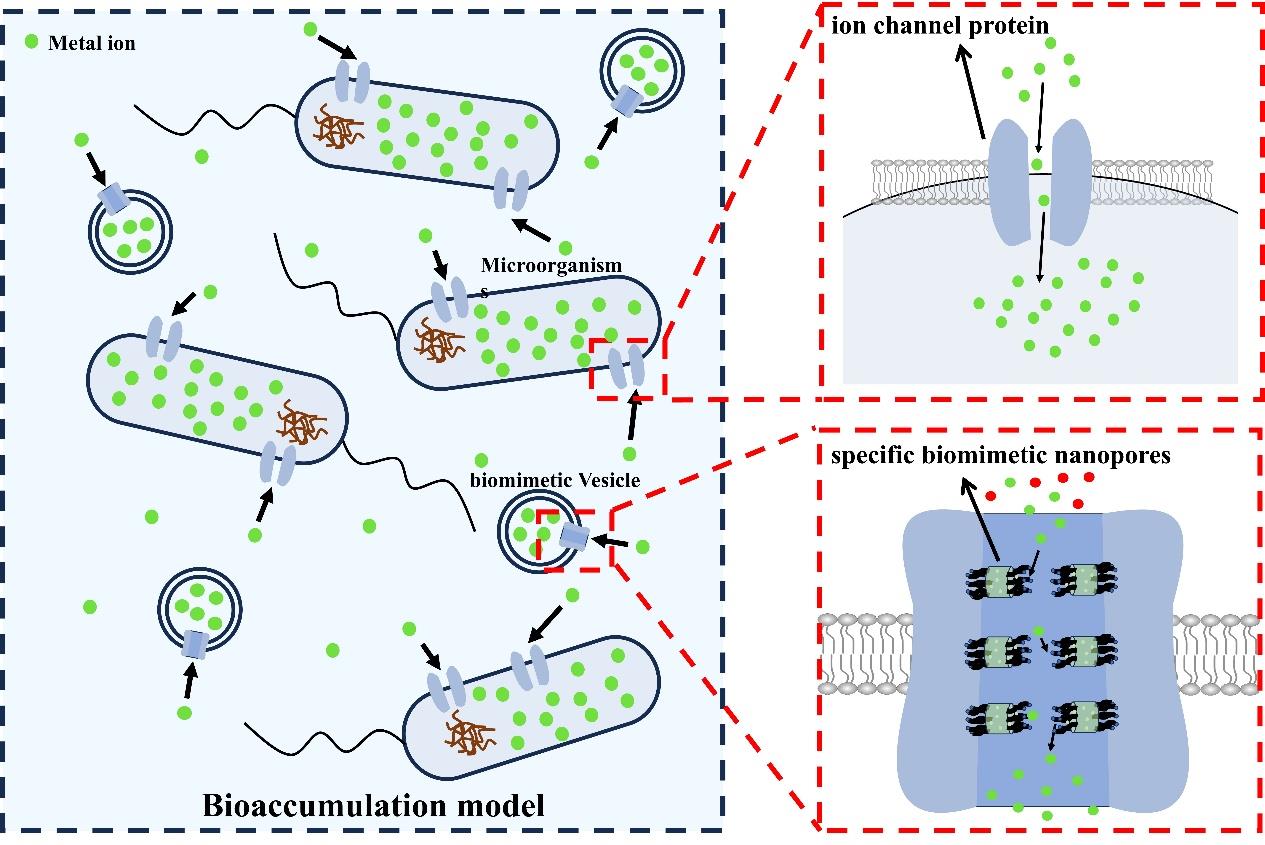

随着新一轮能源革命的加速推进,锂离子电池作为核心储能器件正迎来爆发式增长。然而快速增长的产能背后,大量退役电池引发的资源浪费和环境污染问题日益凸显。这些废弃电池中蕴藏着丰富的锂、钴、镍等高价值战略金属资源,若不妥善回收,不仅造成巨大经济损失,还会因重金属泄露对生态环境构成严重威胁。传统的火法冶金和湿法冶金回收工艺都存在能耗高、污染重等问题,难以满足绿色发展需求。生物法回收技术凭借其低碳排放、低运营成本和环境友好的显著优势,已成为当前研究热点。本文系统阐述了生物浸出、生物吸附、生物富集和生物矿化等生物法回收技术的核心机制,详细分析了微生物代谢产酸浸出、功能菌株筛选吸附、基因工程改造以及矿化产物应用等关键环节的技术突破。生物法回收不仅可缓解关键金属资源短缺,还将推动绿色冶金领域的革新,为循环经济提供新的技术范式,有望在未来逐步实现工业化应用,助力全球锂电产业的可持续发展。

中图分类号:

引用本文

朱思羽, 赵炫烨, 虞雯静, 曹竞天, 刘思慧, 钱文达, 贾海洋. 生物法回收电池关键金属研究进展[J]. 合成生物学, DOI: 10.12211/2096-8280.2025-022.

ZHU Siyu, ZHAO Xuanye, YU Wenjing, CAO Jingtian, LIU Sihui, QIAN Wenda, JIA Haiyang. Advances in Biological Recovery of Key Battery Metals[J]. Synthetic Biology Journal, DOI: 10.12211/2096-8280.2025-022.

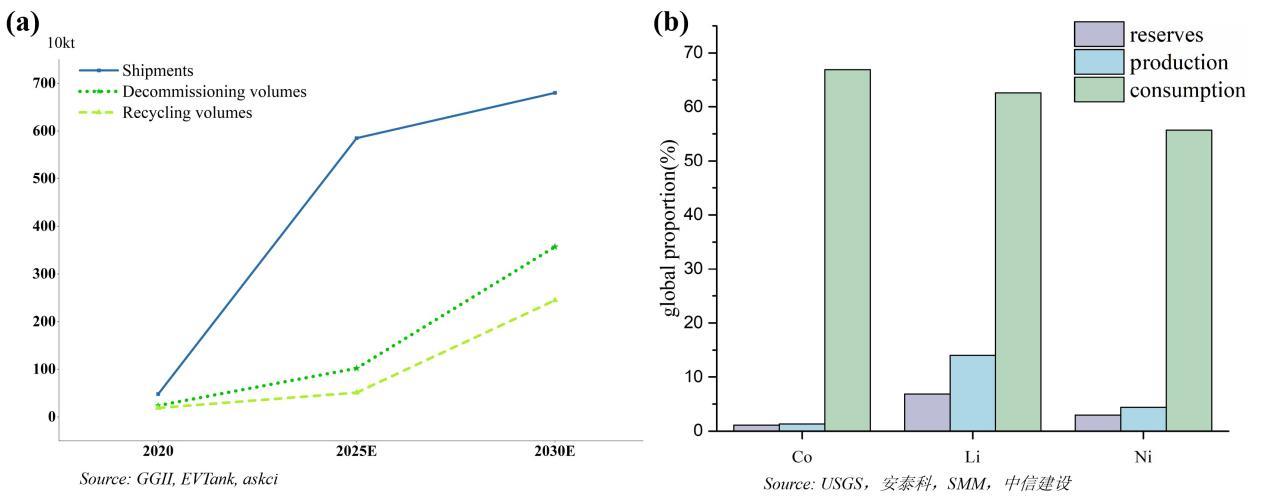

图1 锂离子电池发展趋势(a) 预计中国动力电池出货量(蓝色直线)、报废量(深绿色点线)和回收量(浅绿色划线),数据来源于GGII, EVTank, askci(b) 锂离子电池关键金属(锂、钴、镍)中国储量、产量、消费量全球占比,数据来源于USGS、安泰科、SMM、中信建设)

Fig. 1 Lithium-ion battery development trends(a) Estimated Chinese power battery shipments (blue line), end-of-life (dark green dotted line), and recycling (light green lines), data sourced from GGII, EVTank, askci(b) Global share of China's reserves, production, and consumption of key metals for lithium-ion batteries (lithium, cobalt, and nickel), data Sourced from USGS, Antaike, SMM, CITIC Construction

| 指标 | 火法冶金 | 湿法冶金 | 生物回收 |

|---|---|---|---|

| 设备投资 | 最高(>1000万美元) | 中等(500万-800万美元) | 最低(<200万美元) |

| 能源消耗 | 极高(反应温度>1000 ℃) | 高(化学试剂加热至60-90 ℃) | 低(常温常压) |

| 碳排放 | ~3.5吨CO₂/吨电池 | ~1.8吨CO₂/吨电池 | <0.5吨CO₂/吨电池 |

| 金属回收率 | 锂<50%,钴/镍80%~85% | 锂70%~85%,钴/镍>95% | 锂60%~80%,钴/镍85%~90% |

| 废水/废气 | 高(NOx/SO₂排放) | 酸性废水(pH<2,2—3吨/吨电池)含重金属离子(钴、镍);处理成本>40% | 可忽略(无害微生物代谢物;微生物可循环利用) |

| 运营成本 | 5000-8000美元/吨 | 3000-5000美元/吨 | 预估1000-2000美元/吨 |

| 规模化程度 | 成熟技术(占全球产能35%) | 主导技术(占全球产能60%) | 实验室/中试阶段 |

表1 火法冶金、湿法冶金与生物法的综合对比[31-36]

Table 1 Comprehensive comparison of pyrometallurgy, hydrometallurgy and bioprocesses[31-36]

| 指标 | 火法冶金 | 湿法冶金 | 生物回收 |

|---|---|---|---|

| 设备投资 | 最高(>1000万美元) | 中等(500万-800万美元) | 最低(<200万美元) |

| 能源消耗 | 极高(反应温度>1000 ℃) | 高(化学试剂加热至60-90 ℃) | 低(常温常压) |

| 碳排放 | ~3.5吨CO₂/吨电池 | ~1.8吨CO₂/吨电池 | <0.5吨CO₂/吨电池 |

| 金属回收率 | 锂<50%,钴/镍80%~85% | 锂70%~85%,钴/镍>95% | 锂60%~80%,钴/镍85%~90% |

| 废水/废气 | 高(NOx/SO₂排放) | 酸性废水(pH<2,2—3吨/吨电池)含重金属离子(钴、镍);处理成本>40% | 可忽略(无害微生物代谢物;微生物可循环利用) |

| 运营成本 | 5000-8000美元/吨 | 3000-5000美元/吨 | 预估1000-2000美元/吨 |

| 规模化程度 | 成熟技术(占全球产能35%) | 主导技术(占全球产能60%) | 实验室/中试阶段 |

| 细菌(以下部分标记*的为古菌) | 真菌 | ||

|---|---|---|---|

嗜中温菌 (Mesophiles, 28 °C-37 °C, pH 1.5~2.0) | 中度嗜热菌 (Moderate thermophiles, 40 °C-60°C, pH 1.5-2.5) | 嗜热菌 (Thermophiles, 60°C- 80 °C, pH 1.0-4.0) | (Fungi, 25°C- 35°C, pH 3.0-7.0) |

亚铁氧化酸硫杆状菌 (Acidithiobacillus ferrooxidans) | 喜温酸硫杆状菌 (Acidithiobacillus caldus) | 金属硫化叶菌* (Sulfolobus metallicus) | 黑曲霉 (Aspergillus niger) |

硫氧化酸硫杆状菌 (Acidithiobacillus thiooxidans) | 嗜铁钩端螺菌 (Leptospirillum ferriphilum) | 嗜酸热硫化叶菌* (Sulfolobus acidocaldarius) | 简青霉 (Penicillium simplicissimum) |

| 氧化铁钩端螺菌(Leptospirillum ferrooxidans) | 嗜酸硫化杆菌 (Sulfobacillus acidophilus) | 硫磺矿硫化叶菌* (Sulfolobus solfataricus) | 产黄青霉 (Penicillium chrysogenum) |

阿尔伯塔酸硫杆状菌 (Acidithiobacillus albertensis) | 嗜酸热原体菌* (Thermoplasma acidophilum) | 布氏硫化叶菌* (Sulfolobus brierley) | 黄曲霉 (Aspergillus flavus) |

| 食铁嗜酸硫杆菌(Acidithiobacillus Ferridurans) | 嗜酸铁原体菌* (Ferroplasma acidiphilum) | 双能硫化叶菌* (Sulfolobus ambioalous) | 烟曲霉 (Aspergillus fumigatus) |

嗜酸喜酸菌 (Acidiphilium acidophilum) | 嗜酸铁原体嗜酸亚种* (Ferroplasma acidarmanus) | 勤奋生金球菌*(Metallosphaera sedula) | 米曲霉 (Aspergillus oryzae) |

铁氧化酸微菌 (Acidimicrobium ferrooxidans) | 嗜热铁原体菌* (Ferroplasma thermophilum) | 嗜热硫氧化硫化杆菌(Sulfobacillus thermosulfidooxidans) | 土曲霉 (Aspergillus terreus) |

多食嗜酸菌 (Acidiphilium multivorum) | 环庚基脂环酸芽孢杆菌 (Alicyclobacillus cycloheptanicus) | ||

嗜铁酸硫杆状菌 (Acidithiobacillus ferriphilus) | |||

食铁硫酸杆状菌 (Acidithiobacillus ferrivorans) | |||

食有机物氧化亚铁嗜酸芽孢杆菌 (Ferroacidibacillus organovorans) | |||

表2 常见用于金属浸出的细菌和真菌[9, 42-44]

Table 2 Bacteria and fungi commonly used in metal bioleaching[9, 42-44]

| 细菌(以下部分标记*的为古菌) | 真菌 | ||

|---|---|---|---|

嗜中温菌 (Mesophiles, 28 °C-37 °C, pH 1.5~2.0) | 中度嗜热菌 (Moderate thermophiles, 40 °C-60°C, pH 1.5-2.5) | 嗜热菌 (Thermophiles, 60°C- 80 °C, pH 1.0-4.0) | (Fungi, 25°C- 35°C, pH 3.0-7.0) |

亚铁氧化酸硫杆状菌 (Acidithiobacillus ferrooxidans) | 喜温酸硫杆状菌 (Acidithiobacillus caldus) | 金属硫化叶菌* (Sulfolobus metallicus) | 黑曲霉 (Aspergillus niger) |

硫氧化酸硫杆状菌 (Acidithiobacillus thiooxidans) | 嗜铁钩端螺菌 (Leptospirillum ferriphilum) | 嗜酸热硫化叶菌* (Sulfolobus acidocaldarius) | 简青霉 (Penicillium simplicissimum) |

| 氧化铁钩端螺菌(Leptospirillum ferrooxidans) | 嗜酸硫化杆菌 (Sulfobacillus acidophilus) | 硫磺矿硫化叶菌* (Sulfolobus solfataricus) | 产黄青霉 (Penicillium chrysogenum) |

阿尔伯塔酸硫杆状菌 (Acidithiobacillus albertensis) | 嗜酸热原体菌* (Thermoplasma acidophilum) | 布氏硫化叶菌* (Sulfolobus brierley) | 黄曲霉 (Aspergillus flavus) |

| 食铁嗜酸硫杆菌(Acidithiobacillus Ferridurans) | 嗜酸铁原体菌* (Ferroplasma acidiphilum) | 双能硫化叶菌* (Sulfolobus ambioalous) | 烟曲霉 (Aspergillus fumigatus) |

嗜酸喜酸菌 (Acidiphilium acidophilum) | 嗜酸铁原体嗜酸亚种* (Ferroplasma acidarmanus) | 勤奋生金球菌*(Metallosphaera sedula) | 米曲霉 (Aspergillus oryzae) |

铁氧化酸微菌 (Acidimicrobium ferrooxidans) | 嗜热铁原体菌* (Ferroplasma thermophilum) | 嗜热硫氧化硫化杆菌(Sulfobacillus thermosulfidooxidans) | 土曲霉 (Aspergillus terreus) |

多食嗜酸菌 (Acidiphilium multivorum) | 环庚基脂环酸芽孢杆菌 (Alicyclobacillus cycloheptanicus) | ||

嗜铁酸硫杆状菌 (Acidithiobacillus ferriphilus) | |||

食铁硫酸杆状菌 (Acidithiobacillus ferrivorans) | |||

食有机物氧化亚铁嗜酸芽孢杆菌 (Ferroacidibacillus organovorans) | |||

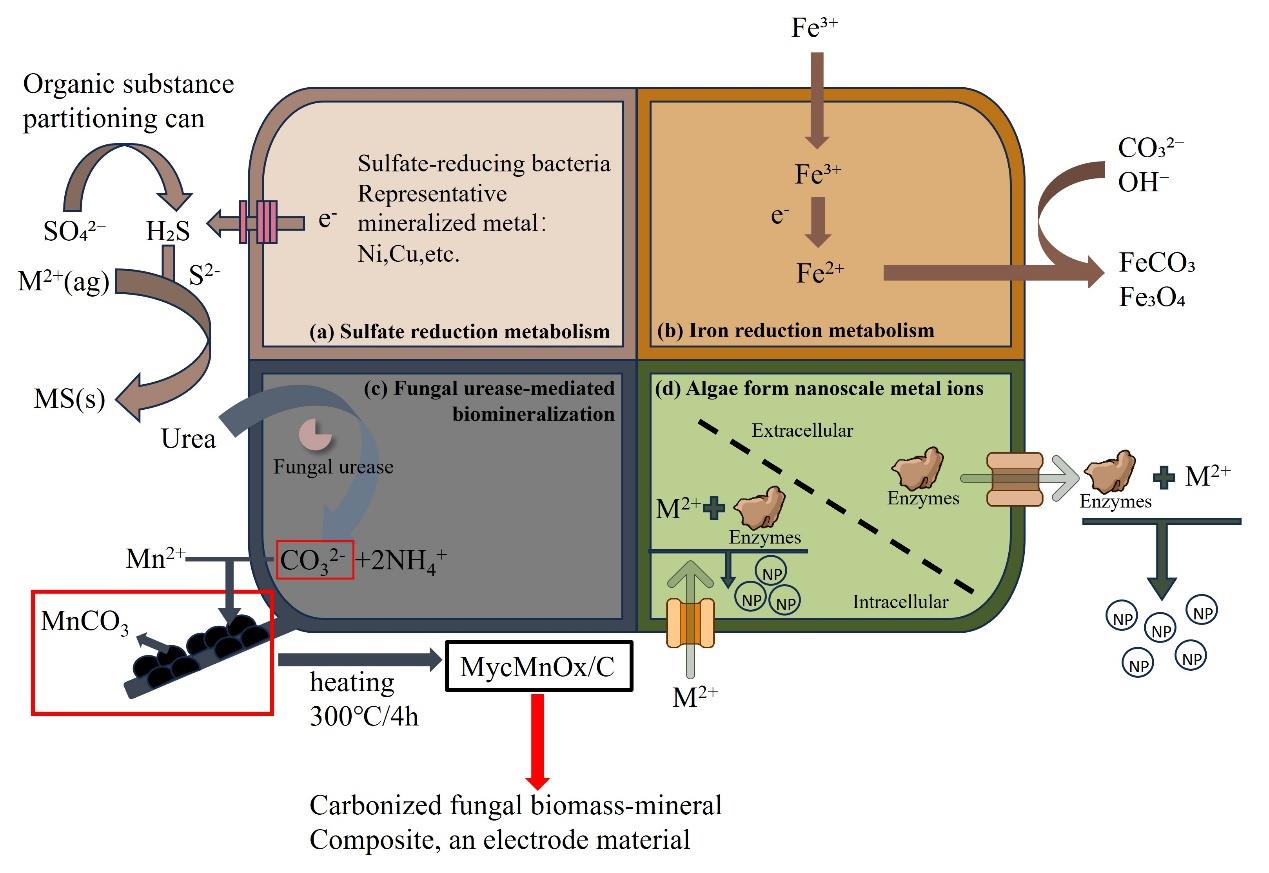

图7 基于微生物的生物矿化过程(a)硫酸盐还原代谢;(b)铁还原代谢;(c)真菌脲酶介导的生物矿化;(d)藻类形成纳米级金属离子

Fig. 7 Microbial-based biomineralization process and preparation of electrode materials (a) Sulfate reduction metabolism; (b) Iron reduction metabolism; (c) Fungal urease-mediated biomineralization; (d) Algae form nanoscale metal ions

| 1 | CHU S, MAJUMDAR A. Opportunities and challenges for a sustainable energy future[J]. Nature, 2012, 488(7411): 294-303. |

| 2 | DEGEN F, WINTER M, BENDIG D, et al. Energy consumption of current and future production of lithium-ion and post lithium-ion battery cells[J]. Nature Energy, 2023, 8(11): 1284-1295. |

| 3 | LARCHER D, TARASCON J M. Towards greener and more sustainable batteries for electrical energy storage[J]. Nature Chemistry, 2015, 7(1):19-29. |

| 4 | PLACKE T, KLOEPSCH R, DÜHNEN S, et al. Lithium ion, lithium metal, and alternative rechargeable battery technologies: the odyssey for high energy density[J]. Journal of Solid State Electrochemistry, 2017, 21(7): 1939-1964. |

| 5 | AIE, Global EV Outlook 2023: Catching up with Climate Ambitions[R]. Paris: OECD Publishing, 2023, 92-64-85692-7. |

| 6 | EVTANK, «中国锂离子电池回收拆解与梯次利用行业发展白皮书(2024年)»[R], 2024. |

| EVTANK, China Lithium-ion Battery Recycling, Disassembly and Recycling Industry Development White Paper (2024)[R], 2024. | |

| 7 | CASTELVECCHI D, Electric cars and batteries: how will the world produce enough[J]? Nature, 2021. 596: 336-339. |

| 8 | WANG H, FENG K S, WANG P, et al. China's electric vehicle and climate ambitions jeopardized by surging critical material prices[J]. Nature Communications, 2023, 14(1): 1246. |

| 9 | ROY J J, CAO B, MADHAVI S. A review on the recycling of spent lithium-ion batteries (LIBs) by the bioleaching approach[J]. Chemosphere, 2021, 282: 130944. |

| 10 | MROZIK W, RAJAEIFAR M A, HEIDRICH O, et al. Environmental impacts, pollution sources and pathways of spent lithium-ion batteries[J]. Energy & Environmental Science, 2021, 14(12): 6099-6121. |

| 11 | BANZA LUBABA NKULU C, CASAS L, HAYFROID V, et al. Sustainability of artisanal mining of cobalt in DR Congo[J]. Nature Sustainability, 2018, 1(9): 495-504. |

| 12 | Xu C J, BEHRENS P, GASPER P, et al. Electric vehicle batteries alone could satisfy short-term grid storage demand by as early as 2030[J]. Nature Communications, 2023, 14(1): 119. |

| 13 | LI Y K, LV W G, HUANG H L, et al. Recycling of spent lithium-ion batteries in view of green chemistry[J]. Green Chemistry, 2021, 23(17): 6139-6171. |

| 14 | RAUTELA R, YADAV B R, KUMAR S. A review on technologies for recovery of metals from waste lithium-ion batteries[J]. Journal of Power Sources, 2023, 580: 233428. |

| 15 | SAYILGAN E, KUKRER T, CIVELEKOGLU G, et al. A review of technologies for the recovery of metals from spent alkaline and zinc–carbon batteries[J]. Hydrometallurgy, 2009, 97(3): 158-166. |

| 16 | BLUMBERGS E, SERGA V, PLATACIS E, et al. Cadmium Recovery from Spent Ni-Cd Batteries: A Brief Review[J]. Metals, 2021, 11(11): 1714. |

| 17 | PRADHAN S, NAYAK R, MISHRA S. A review on the recovery of metal values from spent nickel metal hydride and lithium-ion batteries[J]. International Journal of Environmental Science and Technology, 2022, 19(5): 4537–4554. |

| 18 | SILVESTRI L, FORCINA A, SILVERSTRI C, et al. Circularity potential of rare earths for sustainable mobility: Recent developments, challenges and future prospects[J]. Journal of Cleaner Production, 2021, 292: 126089. |

| 19 | ZHANG G Q, LI L M, CHOI S. Robotic automated battery sorting system[C]. in 2012 IEEE International Conference on Technologies for Practical Robot Applications (TePRA), Woburn, MA, USA, 2012, p. 117-120, doi:10.1109/TePRA.2012.6215664 . |

| 20 | WANG L, LIU J R, YE Q, et al. Sorting method of lithium-ion batteriesinmass production[J]. IOP Conference Series: Earth and Environmental Science, 2020, 512(1): 012127. |

| 21 | CHEN X P, LUO C B, ZHANG J X, et al. Sustainable Recovery of Metals from Spent Lithium-Ion Batteries: A Green Process[J]. ACS Sustainable Chemistry & Engineering, 2015, 3(12): 3104-3113. |

| 22 | ZHENG R J, WANG W H, DAI Y K, et al. A closed-loop process for recycling LiNixCoyMn(1-x-y)O2 from mixed cathode materials of lithium-ion batteries[J]. Green Energy & Environment, 2017, 2(1): 42-50. |

| 23 | DORELLA G, MANSUR M B. A study of the separation of cobalt from spent Li-ion battery residues[J]. Journal of Power Sources, 2007, 170(1): 210-215. |

| 24 | GOODENOUGH J B, PARK K S. The Li-Ion Rechargeable Battery: A Perspective[J]. Journal of the American Chemical Society, 2013, 135(4): 1167-1176. |

| 25 | ZHANG T, HE Y Q, WANG F F, et al. Chemical and process mineralogical characterizations of spent lithium-ion batteries: An approach by multi-analytical techniques[J]. Waste Management, 2014, 34(6): 1051-1058. |

| 26 | WANG X, GAUSTAD G, BABBITT C W. Targeting high value metals in lithium-ion battery recycling via shredding and size-based separation[J]. Waste Management, 2016, 51: 204-213. |

| 27 | WANG H F, LIU J S, BAI X J, et al. Separation of the cathode materials from the Al foil in spent lithium-ion batteries by cryogenic grinding[J]. Waste Management, 2019, 91: 89-98. |

| 28 | SADEGHI MARYAM S, JESUS J, SOARES H M V M. A critical updated review of the hydrometallurgical routes for recycling zinc and manganese from spent zinc-based batteries[J]. Waste Management, 2020, 113: 342-350. |

| 29 | HU X F, ROBLES A, VIKSTRÖM T, et al. A novel process on the recovery of zinc and manganese from spent alkaline and zinc-carbon batteries[J]. Journal of Hazardous Materials, 2021, 411: 124928. |

| 30 | HUA Y, ZHOU S D, HUANG Y,, et al. Sustainable value chain of retired lithium-ion batteries for electric vehicles[J]. Journal of Power Sources, 2020, 478: 228753. |

| 31 | FADLIAH, RAYA I, TABA P, et al. The advances in the recovery process for precious metals from nickel slag, a review[J]. IOP Conference Series: Earth and Environmental Science, 2024, 1339: 012030. |

| 32 | BISWAL B K, BALASUBRAMANIAN R. Recovery of valuable metals from spent lithium-ion batteries using microbial agents for bioleaching: a review[J]. Frontiers in Microbiology, 2023, 14: 1197081. |

| 33 | 郭丽丽, 动力电池回收:从"0"到"1000",尽享行业发展红利[R]. 2022. |

| GUO L L. Power Battery Recycling: From "0" to "1000", Enjoying the Dividends of Industry Development[R]. 2022. | |

| 34 | 郭宇,于刚强,陈标华. 废锂离子电池的冶金回收工艺研究进展[J]. 北京工业大学学报, 2024, 50(2): 230-245. |

| GUO Y, YU G Q, CHEN B H. Progress of metallurgical recovery process of waste lithium-ion batteries[J]. Journal of Beijing Institute of Technology, 2024, 50(2): 230-245. | |

| 35 | BENZAL MONTES E. Study and optimisation of copper bioleaching process for electronic waste valorisation[D]. Universitat Politècnica de Catalunya (UPC), Departament d'Enginyeria Minera, Industrial i TIC, 2021. DOI: 10.5821/dissertation-2117-346006 . |

| 36 | WANG N B, GARG A, SU S S, et al., Echelon Utilization of Retired Power Lithium-Ion Batteries: Challenges and Prospects[J]. Batteries, 2022, 8(8): 96. |

| 37 | VINCI G, ARANGIA V C, RUGGIERI R, et al. Reuse of Lithium Iron Phosphate (LiFePO4) Batteries from a Life Cycle Assessment Perspective: The Second-Life Case Study[J]. Energies, 2024, 17(11): 2544. |

| 38 | TEAM C S. CAS Insights Report: lithium-ion-battery-recycling-trends[R]. Chemical Abstracts Service (CAS), 2025. |

| 39 | SANTHIYA D, TING Y P. Use of adapted Aspergillus niger in the bioleaching of spent refinery processing catalyst[J]. Journal of Biotechnology, 2006, 121(1): 62-74. |

| 40 | BOSECKER K. Bioleaching: metal solubilization by microorganisms[J]. FEMS Microbiology Reviews, 1997. 20(3): 591-604. |

| 41 | PATHAK A, KOTHARI R, VINOBA M, et al. Fungal bioleaching of metals from refinery spent catalysts: A critical review of current research, challenges, and future directions[J]. Journal of Environmental Management, 2021, 280: 111789. |

| 42 | DUSENGEMUNGU L, KASALI G, GWANAMA C, et al. Overview of fungal bioleaching of metals[J]. Environmental Advances, 2021, 5: 100083. |

| 43 | DEVI A S, GANESH S. Recent bioleaching approaches employed for the extraction of metals in mining fields for the purpose of utilization and creating the sustainable future[J]. Environmental Quality Management, 33(4), 317–333. |

| 44 | YUN S, JUNG H, LEE H J, et al. Bioleaching of valuable metals from three cathode active materials comprising lithium nickel cobalt manganese (NCM) oxide using indigenous microorganisms[J]. Journal of Industrial and Engineering Chemistry, 2024, 135: 552-560. |

| 45 | MISHRA D, KIM D J, RALPH D E, et al. Bioleaching of metals from spent lithium ion secondary batteries using Acidithiobacillus ferrooxidans [J]. Waste Management, 2008, 28(2): 333-338. |

| 46 | XIN B, ZHANG D, ZHANG X, et al. Bioleaching mechanism of Co and Li from spent lithium-ion battery by the mixed culture of acidophilic sulfur-oxidizing and iron-oxidizing bacteria[J]. Bioresource Technology, 2009, 100(24): 6163-6169. |

| 47 | WU W J, LIU X C, LI X Y, et al. Mechanism underlying the bioleaching process of LiCoO2 by sulfur-oxidizing and iron-oxidizing bacteria[J]. Journal of Bioscience and Bioengineering, 2019, 128(3): 344-354. |

| 48 | XIN Y Y, GUO X M, CHEN S, et al. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery[J]. Journal of Cleaner Production, 2016, 116: 249-258. |

| 49 | HEYDARIAN A, MOUSAVI S M, VAKILCHAP F, et al., Application of a mixed culture of adapted acidophilic bacteria in two-step bioleaching of spent lithium-ion laptop batteries[J]. Journal of Power Sources, 2018, 378: 19-30. |

| 50 | ROY J J, ZAIDEN N, DO M P, et al. Microbial recycling of lithium-ion batteries: Challenges and outlook[J]. Joule, 2023, 7(3): 450-456. |

| 51 | ILYAS S, KIM M S, LEE J C. Integration of microbial and chemical processing for a sustainable metallurgy[J]. Journal of Chemical Technology & Biotechnology, 2018, 93(2): 320-332. |

| 52 | ILYAS S, ANWAR M A, NIAZI, et al. Bioleaching of metals from electronic scrap by moderately thermophilic acidophilic bacteria[J]. Hydrometallurgy, 2007, 88(1): 180-188. |

| 53 | PLESSIS C A D, BATTY J D, DEW D W. Commercial Applications of Thermophile Bioleaching, in Biomining[M], Springer Berlin Heidelberg: Berlin, Heidelberg, 2007, p: 57-80. |

| 54 | BISWAL B K, JADHAV U U, MADHAIYAN M, et al. Biological Leaching and Chemical Precipitation Methods for Recovery of Co and Li from Spent Lithium-Ion Batteries[J]. ACS Sustainable Chemistry & Engineering, 2018, 6(9): 12343-12352. |

| 55 | BAHALOO-HOREH N, MOUSAVI S M. Enhanced recovery of valuable metals from spent lithium-ion batteries through optimization of organic acids produced by Aspergillus niger [J]. Waste Management, 2017, 60: 666-679. |

| 56 | MISHRA D, RHEE Y H. Microbial leaching of metals from solid industrial wastes[J]. Journal of Microbiology, 2014, 52(1): 1-7. |

| 57 | AMIRI F, MOUSAVI S M, YAGHMAEI S, et al. Bioleaching kinetics of a spent refinery catalyst using Aspergillus niger at optimal conditions[J]. Biochemical Engineering Journal, 2012, 67: 208-217. |

| 58 | MOSSALI E, PICONE N, GENTILINI L, et al. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments[J]. Journal of Environmental Management, 2020, 264: 110500. |

| 59 | KAPOOR A, VIRARAGHAVAN T. Viraraghavan, Fungal biosorption — an alternative treatment option for heavy metal bearing wastewaters: a review[J]. Bioresource Technology, 1995, 53(3): 195-206. |

| 60 | BAYRAKTAR O. Bioleaching of nickel from equilibrium fluid catalytic cracking catalysts[J]. World Journal of Microbiology and Biotechnology, 2005, 21(5): 661-665. |

| 61 | RAWLINGS D E. Heavy Metal Mining Using Microbes1[J]. Annual Review of Microbiology, 2002, 56: 65-91. |

| 62 | NADERI M, SHAFAIE S Z, KARAMOOZIAN M, et al. Optimization of parameters affecting recovery of copper from Sarcheshmeh low-grade sulfide ore using Bioleaching[J]. Journal of Mining and Environment, 2017, 8(4): 523-537. |

| 63 | DAS S, DESHAVATH N N, GOUD V V, et al. Bioleaching of Al from spent fluid catalytic cracking catalyst using Aspergillus species[J]. Biotechnology Reports, 2019, 23: e00349. |

| 64 | HAMAD H O, MEHMET A, ISMAEL H M, et al. The Effect of Some Sugars on the Growth of Aspergillus niger [J]. Kahramanmaraş Sütçü İmam Üniversitesi Doğa Bilimleri Dergisi, 2015, 17: 7. |

| 65 | 熊结青,杨儒文,佟毅,等.黑曲霉种子及其制备方法以及黑曲霉发酵产柠檬酸的方法[P].CN202110901105.4.2023. |

| XIONG J Q, YANG R W, TONG Y, et al. Aspergillus niger seed and its preparation method and the method of citric acid production by fermentation of Aspergillus niger [P].CN202110901105.4.2023. | |

| 66 | 刘浩,徐永学.一种高产L-苹果酸的黑曲霉基因工程菌株及其构建与应用[P].CN201810985901.9.2019. |

| LIU H, XU Y X. A genetically engineered strain of Aspergillus niger with high production of L-malic acid and its construction and application[P].CN201810985901.9.2019. | |

| 67 | BEHERA B C. Citric acid from Aspergillus niger: a comprehensive overview[J]. Critical Reviews in Microbiology, 2020, 46(6): 727-749. |

| 68 | BALLESTER A, BLAZQUEZ M L, GONZALEZ F, et al.,Catalytic Role of Silver and Other Ions on The Mechanism of Chemical and Biological Leaching[M]. Springer Netherlands: Dordrecht, 2007, p. 77-101. |

| 69 | ROY J J, MADHAVI S, CAO B. Metal extraction from spent lithium-ion batteries (LIBs) at high pulp density by environmentally friendly bioleaching process[J]. Journal of Cleaner Production, 2021, 280: 124242. |

| 70 | SETHURAJAN M, GAYDARDZHIEV S. Bioprocessing of spent lithium ion batteries for critical metals recovery – A review[J]. Resources, Conservation and Recycling, 2021, 165: 105225. |

| 71 | HOREH N B, MOUSAVI S M, SHOJAOSADATI S A. Shojaosadati, Bioleaching of valuable metals from spent lithium-ion mobile phone batteries using Aspergillus niger [J]. Journal of Power Sources, 2016. 320: 257-266. |

| 72 | BAHALOO-HOREH N, VAKILCHAP F, MOUSAVI S M. Bio-hydrometallurgical Methods For Recycling Spent Lithium-Ion Batteries[M]. Springer International Publishing: Cham, 2019, p. 161-197. |

| 73 | LALROPUIA L, KUCERA J, RASSY W Y, et al. Metal recovery from spent lithium-ion batteries via two-step bioleaching using adapted chemolithotrophs from an acidic mine pit lake[J]. Frontiers in Microbiology, 2024, 15: 1347072. |

| 74 | GU Z Y, AIKEBAIER Y, AREFIEVA V, et al. Using microbiological leaching method to remove heavy metals from sludge[J]. Eurasian Journal of Soil Science, 2017, 6: 51-58. |

| 75 | KANESALINGAM B, FERNANDO W A M, PANDA S, et al. Harnessing the Capabilities of Microorganisms for the Valorisation of Coal Fly Ash Waste through Biometallurgy[J]. Minerals, 2023, 13(6): 724. |

| 76 | ROY J J, RAROTRA S, KRIKSTOLAITYTE V, et al. Green Recycling Methods to Treat Lithium-Ion Batteries E-Waste: A Circular Approach to Sustainability[J]. Advanced Materials, 2022, 34(25): 2103346. |

| 77 | MADRIGAL-ARIAS J E, ARGUMEDO-DELIRA R, ALARCÓN A, et al. Bioleaching of gold, copper and nickel from waste cellular phone PCBs and computer goldfinger motherboards by two Aspergillus niger strains[J]. Brazilian Journal of Microbiology, 2015, 46(3): 707-713. |

| 78 | HANSDA A, KUMAR V, ANSHUMALI. A comparative review towards potential of microbial cells for heavy metal removal with emphasis on biosorption and bioaccumulation[J]. World Journal of Microbiology and Biotechnology, 2016. 32(10): 170. |

| 79 | MOREIRA Y H B, MANTEGAZINI D, ANDRADE G R S, et al. Reciclagem de baterias de íon-lítio: uma breve revisão sobre os processos, avanços e perspectivas[J]. Brazilian Journal of Production Engineering, 2024, 10(1): 36-52. |

| 80 | WANG J, CHEN C. Biosorbents for heavy metals removal and their future[J]. Biotechnology Advances, 2009, 27(2): 195-226. |

| 81 | 朴永哲,黄玮,崔玉波.细菌对重金属的抗性及解毒机理研究进展[J].安全与环境学报, 2015, 15(6):5. |

| PARK Y C, HUANG W, CUI Y B. Progress in the study of bacterial resistance to heavy metals and detoxification mechanism[J]. Journal of Safety and Environment, 2015, 15(6):5. | |

| 82 | YE J S, YIN H, MAI B X, et al. Biosorption of chromium from aqueous solution and electroplating wastewater using mixture of Candida lipolytica and dewatered sewage sludge[J]. Bioresour Technol, 2010, 101(11): 3893-902. |

| 83 | SHAHID A, PANDEY C, AHMAD F, et al. Bacterial bioremediation: Strategies adopted by microbial-community to remediate lead from the environment[J]. Journal of Applied Biology & Biotechnology, 2021. |

| 84 | DAUGHNEY C J, HETZER A, HEINRICH H T M, et al. Proton and cadmium adsorption by the archaeon Thermococcus zilligii: Generalising the contrast between thermophiles and mesophiles as sorbents[J]. Chemical Geology, 2010, 273(1): 82-90. |

| 85 | YAN C M, HE Z, GE Z B, et al. Comparative study on adsorption characteristics of lead and cadmium by two heavy metal resistant bacteria[J]. Acta Scientiae Circumstantiae, 2018, 38(9): 3597-3604. |

| 86 | KIRK C. Selective Bacterial Separation of Critical Metals: a Sustainable Method for Recycling Lithium Ion Batteries[R]. American Chemical Society (ACS), 2022. |

| 87 | VÁZQUEZ-ORTEGA A, FEIN J B. Thermodynamic modeling of Mn (II) adsorption onto manganese oxidizing bacteria[J]. Chemical Geology, 2017, 464: 147-154. |

| 88 | NNAJI N D, ANYANWU C U, MIRI T, et al. Mechanisms of Heavy Metal Tolerance in Bacteria: A Review[J]. Sustainability, 2024, 16(24): 11124. |

| 89 | AL-AJALIN F A, IDRIS M, ABDULLAH S R S, et al. Biosorption of Lead and Copper by Epiphytic Rhizobacterial Species Isolated from Lepironia articulata and Scirpus grossus [J]. Journal of Ecological Engineering, 2024, 25(2):44-61. |

| 90 | JARDINE J L. Potential bioremediation of heavy metal ions, polycyclic aromatic hydrocarbons and biofilms with South African hot spring bacteria[J]. Bioremediation Journal, 2022, 26(3): 261-269. |

| 91 | RENDÓN-CASTRILLÓN L, RAMÍREZ-CARMONA M, OCAMPO-LÓPEZ C, et al. Bioleaching Techniques for Sustainable Recovery of Metals from Solid Matrices[J]. Sustainability, 2023. 15(13): p. 10222. |

| 92 | DIEP P, MAHADEVAN R, YAKUNIN A F. Heavy Metal Removal by Bioaccumulation Using Genetically Engineered Microorganisms[J]. Frontiers in Bioengineering and Biotechnology, 2018, 6: 157. |

| 93 | CHOJNACKA K. Biosorption and bioaccumulation – the prospects for practical applications[J]. Environment International, 2010, 36(3): 299-307. |

| 94 | STURINI M, GIROMETTA C, MARASCHI F, et al. A Preliminary Investigation on Metal Bioaccumulation by Perenniporia fraxinea[J]. Bulletin of Environmental Contamination and Toxicology, 2017, 98(4): 508-512. |

| 95 | WIECZOREK J, BARAN A, BUBAK A. Mobility, bioaccumulation in plants, and risk assessment of metals in soils[J]. Science of the Total Environment, 2023, 882: 163574. |

| 96 | YIN K, WANG Q N, LV M, et al. Microorganism remediation strategies towards heavy metals[J]. Chemical Engineering Journal, 2019, 360: 1553-1563. |

| 97 | ZHAO M H, ZHANG C S, ZENG G M, et al. Toxicity and bioaccumulation of heavy metals in Phanerochaete chrysosporium[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(5): 1410-1418. |

| 98 | DENG X, LI Q B, LU Y H, et al. Genetic engineering of E. coli SE5000 and its potential for Ni2+ bioremediation[J]. Process Biochemistry, 2005, 40(1): 425-430. |

| 99 | DENG X, HE J, HE N. Comparative study on Ni2+-affinity transport of nickel/cobalt permeases (NiCoTs) and the potential of recombinant Escherichia coli for Ni2+ bioaccumulation[J]. Bioresource Technology, 2013, 130: 69-74. |

| 100 | DENG X, LI Q B, LU Y H, et al. Bioaccumulation of nickel from aqueous solutions by genetically engineered Escherichia coli [J]. Water Research, 2003, 37(10): 2505-2511. |

| 101 | VALIX M, TANG J Y, MALIK R. Heavy metal tolerance of fungi[J]. Minerals Engineering, 2001, 14(5): 499-505. |

| 102 | DIEP P, SHEN H L, WIESNER J A, et al. Engineered nickel bioaccumulation in Escherichia coli by NikABCDE transporter and metallothionein overexpression[J]. Engineering in Life Sciences, 2023, 23(7): e2200133. |

| 103 | GAHLOT D K, TAHERI N, MAHATO D R, et al. Bioengineering of non-pathogenic Escherichia coli to enrich for accumulation of environmental copper[J]. Scientific Reports, 2020, 10(1): 20327. |

| 104 | YANG J S, CAO J, XING G L, et al. Lipid production combined with biosorption and bioaccumulation of cadmium, copper, manganese and zinc by oleaginous microalgae Chlorella minutissima UTEX2341[J]. Bioresource Technology, 2015, 175: 537-544. |

| 105 | LI G, WANG Y, LUAN H H, et al. Highly Selective Transport and Enrichment of Lithium Ions through Bionic Ion Pair Receptor Nanochannels[J]. ACS Applied Materials & Interfaces, 2023, 15(27): 32753-32761. |

| 106 | BAI X, SUN Y Z, LI X F, et al. A Deep Dive into Spent Lithium-Ion Batteries: from Degradation Diagnostics to Sustainable Material Recovery[J]. Electrochemical Energy Reviews, 2024, 7(1): 33. |

| 107 | BULLEN D. UTILIZATION OF PAENIBACILLUS POLYMYXA IN THE RECOVERY OF LITHIUM BEARING MINERALS[D]. Michigan Technological University, 2021. |

| 108 | ECHAVARRI-BRAVO V, AMARI H, HARTLEY J, et al. Selective bacterial separation of critical metals: towards a sustainable method for recycling lithium ion batteries[J]. Green Chemistry, 2022, 24(21): 8512-8522. |

| 109 | YAN J, WANG S J, ZHONG K Q, et al. Sulfate reduction and heavy metal removal by a novel metal-resistant sulfate-reducing bacterium: mechanism and optimization[J]. Desalination and Water Treatment, 2019, 168: 88-99. |

| 110 | KUMAR M, NANDI M, PAKSHIRAJAN K. Recent advances in heavy metal recovery from wastewater by biogenic sulfide precipitation[J]. Journal of Environmental Management, 2021, 278: 111555. |

| 111 | DENG L Y, REN W Q, LI M, et al. Photoelectrochemical and energy storage properties for metal sulfides regulated by biomineralization of sulfate reducing bacteria[J]. Journal of Cleaner Production, 2022, 340: 130741. |

| 112 | SITTE J, POLLOK K, LANGENHORST F, et al. Nanocrystalline Nickel and Cobalt Sulfides Formed by a Heavy Metal-Tolerant, Sulfate-Reducing Enrichment Culture[J]. Geomicrobiology Journal, 2013, 30(1): 36-47. |

| 113 | ZHANG W Q, LIU H X, YING J, et al. Preparation of nickel–iron sulfide/oxide nanocomposites by biomineralization of sulfate-reducing bacterium for efficient oxygen evolution[J]. Chemical Engineering Journal, 2023, 475: 146211. |

| 114 | HAN X H, WANG F X, ZHENG S L, et al. Morphological, Microstructural, and In Situ Chemical Characteristics of Siderite Produced by Iron-Reducing Bacteria[J]. Environmental Science & Technology, 2024, 58(25): 11016-11026. |

| 115 | YOON Y, KIM B, CHO M. Mineral transformation of poorly crystalline ferrihydrite to hematite and goethite facilitated by an acclimated microbial consortium in electrodes of soil microbial fuel cells[J]. Science of the Total Environment, 2023, 902: 166414. |

| 116 | ŠEBESTA M, VOJTKOVÁ H, CYPRICHOVÁ V, et al. Mycosynthesis of Metal-Containing Nanoparticles—Fungal Metal Resistance and Mechanisms of Synthesis[J]. International Journal of Molecular Sciences, 2022, 23(22): 14084. |

| 117 | BAO P, XIA M C, LIU A, et al. Extracellular polymeric substances (EPS) secreted by Purpureocillium lilacinum strain Y3 promote biosynthesis of jarosite[J]. RSC Advances, 2018, 8(40): 22635-22642. |

| 118 | 用真菌首次合成电池电极材料[J]. 光学精密机械, 2016(2), p: 2. |

| First Synthesis of Battery Electrode Materials from Fungi[J]. Optical Precision Machinery, 2016(2),p: 2. | |

| 119 | KLAUS-JOERGER T, JOERGER R, OLSSON E, et al. Bacteria as workers in the living factory: metal-accumulating bacteria and their potential for materials science[J]. Trends in Biotechnology, 2001, 19(1):15-20. |

| 120 | LI Q W, LIU D Q, JIA Z, et al. Fungal Biomineralization of Manganese as a Novel Source of Electrochemical Materials[J]. Current Biology, 2016, 26(7): 950-955. |

| 121 | VIJAYANANDAN A S, BALAKRISHNAN R M. Biosynthesis of cobalt oxide nanoparticles using endophytic fungus Aspergillus nidulans [J]. Journal of Environmental Management, 2018, 218: 442-450. |

| 122 | BARCIELA P, CARPENA M, LI N Y, et al. Macroalgae as biofactories of metal nanoparticles; biosynthesis and food applications[J]. Advances in Colloid and Interface Science, 2023, 311: 102829. |

| 123 | XIONG W, ZHAO X H, ZHU G X, et al. Silicification-Induced Cell Aggregation for the Sustainable Production of H2 under Aerobic Conditions[J]. Angewandte Chemie International Edition, 2015, 54(41): 11961-11965. |

| 124 | HIGASHI S L, ZHENG Y J, CHAKRABORTY T, et al. Adaptive metal ion transport and metalloregulation-driven differentiation in pluripotent synthetic cells[J]. Nature Chemistry, 2025, 17(1): 54-65. |

| 125 | ZHANG L H, ZHENG X M, CAIRNS T C, et al. Disruption or reduced expression of the orotidine-5′-decarboxylase gene pyrG increases citric acid production: a new discovery during recyclable genome editing in Aspergillus niger [J]. Microbial Cell Factories, 2020, 19(1): 76. |

| 126 | XU K D, TONG Y, LI Y, et al. Efficient, Flexible Autoinduction Expression Systems with Broad Initiation in Bacillus subtilis[J]. ACS Synthetic Biology, 2021, 10(11): 3084-3093. |

| 127 | MA Y, LIN J Q, ZHANG C J, et al. Cd(II) and As(III) bioaccumulation by recombinant Escherichia coli expressing oligomeric human metallothioneins[J]. Journal of Hazardous Materials, 2011. 185(2): 1605-1608. |

| 128 | WU T, QIAN Y J, ZHU Z B, et al. Imine-Linked 3D Covalent Organic Framework Membrane Featuring Highly Charged Sub-1nm Channels for Exceptional Lithium-Ion Sieving[J]. Advanced Materials, 2025, 37(8): 2415509. |

| 129 | ECHAVARRI-BRAVO V, MARSLAND I, JENSEN M B V, et al. Characterization and Reuse of Lithium-ion Battery Cathode Material Recovered Through a Bacterial Process[J]. Advanced Energy Materials. 2025, p: 2405901. |

| 130 | 周雁红,李夏兰,张光亚, 生物大分子介导仿生矿化制备磁性纳米粒子的研究进展 [J]. 化工进展, 2021, 40(5): 2719-2729. |

| ZHOU Y H, LI X L, ZHANG G Y. Progress of biomolecule-mediated biomimetic mineralization for the preparation of magnetic nanoparticles[J]. Chemical Progress, 2021, 40(5): 2719-2729. | |

| 131 | 肖璐, 李寅. 生物固碳:从自然生物到人工合成[J]. 合成生物学, 2022, 3(5): 833-846. |

| XIAO L, LI Y. Biological carbon fixation: from natural to synthetic[J]. Synthetic Biology Journal, 2022, 3(5): 833-846. | |

| 132 | 孙韬, 张卫文, 胡章立, 元英进. 合成生物学助力碳中和:新底盘、新策略与新技术[J]. 合成生物学, 2022,3(5):821-825. |

| SUN T, ZHANG W W, HU Z L, YUAN Y J. Synthetic biology for carbon neutrality: new chassis, new strategies and new technologies[J]. Synthetic Biology, 2022, 3(5): 821-825. |

| [1] | 周廷尧, 罗源, 蒋兴宇. DNA数据存储:保存策略与数据加密[J]. 合成生物学, 2021, 2(3): 371-383. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||