| [1] |

CHATZIVASILEIOU A O, WARD V, EDGAR S M, et al. Two-step pathway for isoprenoid synthesis [J]. Proceedings of the National Academy of Sciences, 2019, 116(2): 506-11.

|

| [2] |

CUI L, XIAO Y, HU W, et al. Enhanced dataset of global marine isoprene emissions from biogenic and photochemical processes for the period 2001–2020 [J]. Earth System Science Data, 2023, 15(12): 5403-25.

|

| [3] |

SANADZE G. Biogenic isoprene (a review) [J]. Russian Journal of Plant Physiology, 2004, 51: 729-41.

|

| [4] |

KUMAR V, JOHNSON B P, DIMAS D A, et al. Novel Homologs of Isopentenyl Phosphate Kinase Reveal Class-Wide Substrate Flexibility [J]. ChemCatChem, 2021, 13(17): 3781-8.

|

| [5] |

WANG C-H, HOU J, DENG H-K, et al. Microbial production of mevalonate [J]. Journal of Biotechnology, 2023, 370: 1-11.

|

| [6] |

GASTALDO C, LIPKO A, MOTSCH E, et al. Biosynthesis of isoprene units in Euphorbia lathyris Laticifers vs. other tissues: MVA and MEP pathways, compartmentation and putative endophytic fungi contribution [J]. Molecules, 2019, 24(23): 4322.

|

| [7] |

KIM J, BAIDOO E E, AMER B, et al. Engineering Saccharomyces cerevisiae for isoprenol production [J]. Metabolic Engineering, 2021, 64: 154-66.

|

| [8] |

ZHENG Y, LIU Q, LI L, et al. Metabolic engineering of Escherichia coli for high-specificity production of isoprenol and prenol as next generation of biofuels [J]. Biotechnology for biofuels, 2013, 6: 1-13.

|

| [9] |

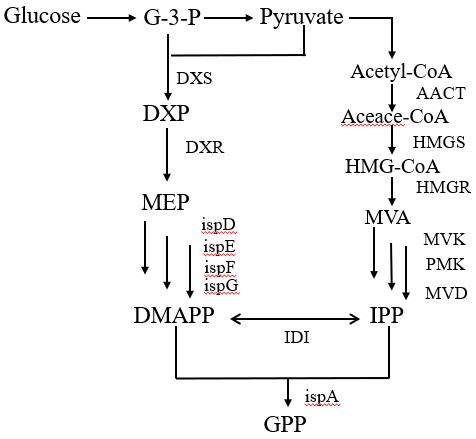

YANG J, NIE Q, LIU H, et al. A novel MVA-mediated pathway for isoprene production in engineered E. coli [J]. BMC biotechnology, 2016, 16: 1-9.

|

| [10] |

YANG C, GAO X, JIANG Y, et al. Synergy between methylerythritol phosphate pathway and mevalonate pathway for isoprene production in Escherichia coli [J]. Metabolic Engineering, 2016, 37: 79-91.

|

| [11] |

ZHANG X-S, LI S, CAI H-X, et al. A DFT study of carbon dioxide reduction catalyzed by group 3 metal complexes of silylamides [J]. Chemical Physics Letters, 2022, 788: 139291.

|

| [12] |

PENG Z, DENG N, LI X, et al. Controllable Preparation, Working Mechanisms, and Actual Application of Various One-Dimensional Nanomaterials as Catalysts for CO2RR: A Review [J]. Industrial & Engineering Chemistry Research, 2023, 62(50): 21511-35.

|

| [13] |

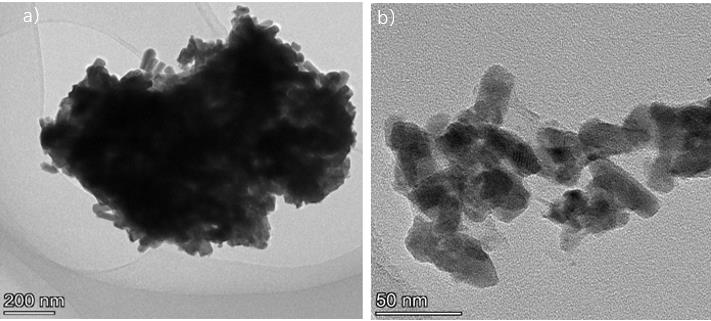

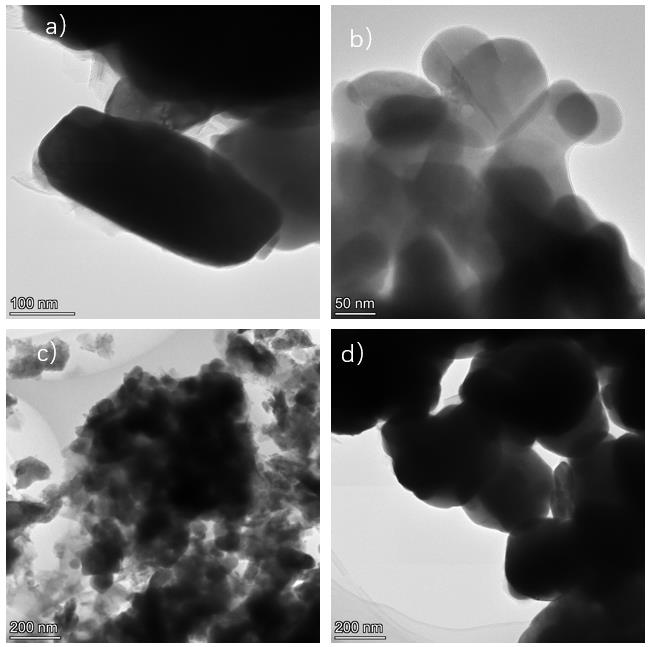

YANG S, JIANG M, ZHANG W, et al. In situ structure refactoring of bismuth nanoflowers for highly selective electrochemical reduction of CO2 to formate [J]. Advanced Functional Materials, 2023, 33(37): 2301984.

|

| [14] |

QIU X F, HUANG J R, YU C, et al. A stable and conductive covalent organic framework with isolated active sites for highly selective electroreduction of carbon dioxide to acetate [J]. Angewandte Chemie, 2022, 134(36): e202206470.

|

| [15] |

LI H, OPGENORTH P H, WERNICK D G, et al. Integrated electromicrobial conversion of CO2 to higher alcohols [J]. Science, 2012, 335(6076): 1596-.

|

| [16] |

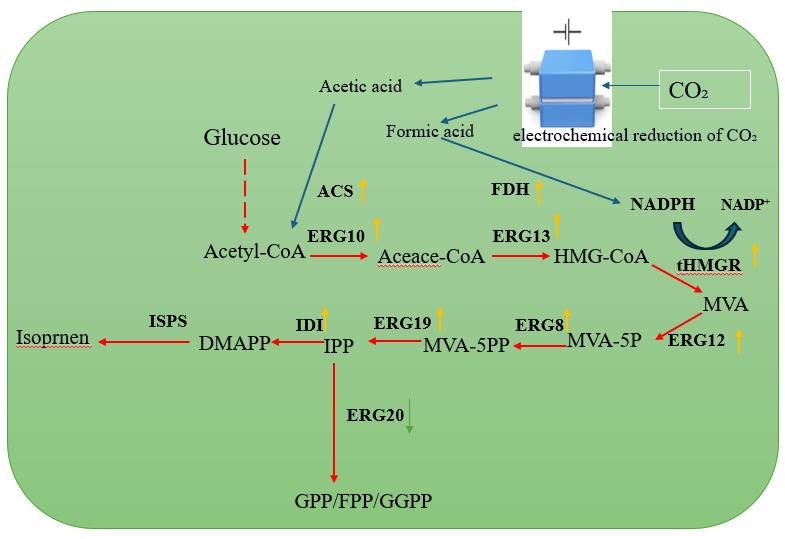

BI H, WANG K, XU C, et al. Biofuel synthesis from carbon dioxide via a bio-electrocatalysis system [J]. Chem Catalysis, 2023, 3(3).

|

| [17] |

LIU Q, BI H, WANG K, et al. Revealing the Mechanisms of Enhanced β-Farnesene Production in Yarrowia lipolytica through Metabolomics Analysis [J]. International Journal of Molecular Sciences, 2023, 24(24): 17366.

|

| [18] |

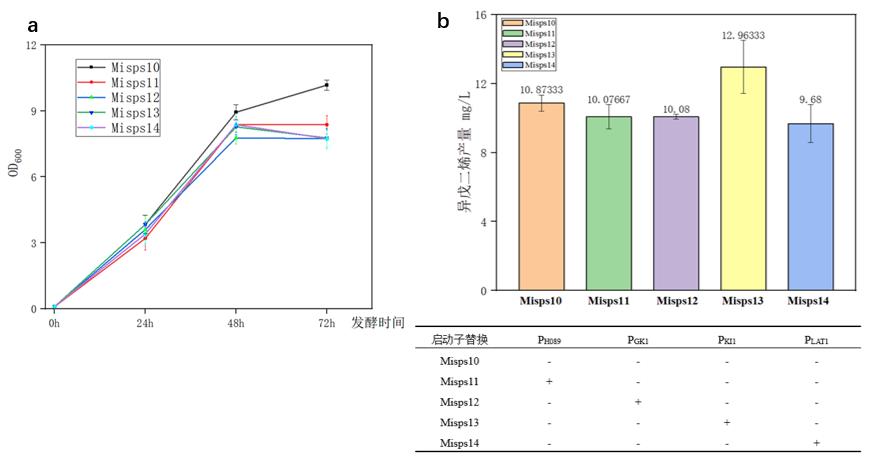

KAMINENI A, CHEN S, CHIFAMBA G, et al. Promoters for lipogenesis-specific downregulation in Yarrowia lipolytica [J]. FEMS Yeast Research, 2020, 20(5): foaa035.

|

| [19] |

DUAN G Y, LI X Q, DU Y R, et al. Efficient electrocatalytic reduction of CO2 to CO on highly dispersed Ag nanoparticles confined by Poly(ionic liquid) [J]. Chemical Engineering Journal, 2023, 455.

|