|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Price to Cost-of-raw-materials Ratio (PC) of biomanufacturing: definition and application

Synthetic Biology Journal

2025, 6 (1):

8-17.

DOI: 10.12211/2096-8280.2024-072

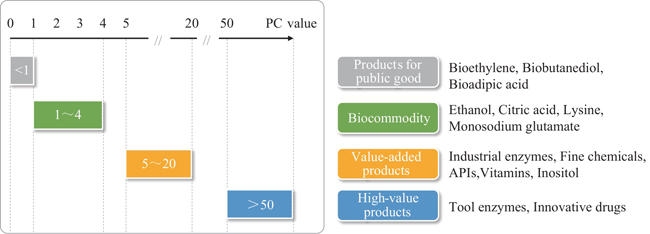

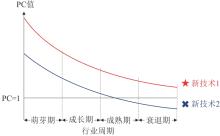

Biomanufacturing is one of the strategic emerging industries in China during the “14th Five-Year Plan” period. The author once proposed “Tao-Fa-Shu-Qi” for the industrial biomanufacturing and provided its philosophical guideline. Focusing on the “Fa” of biological manufacturing and further analyzing the concept of “Fa as rules” in biomanufacturing, the author first proposed the concept of “Price to Cost-of-raw-materials Ratio” (PC value), which is the ratio of product market price to cost with raw materials. Biomanufactured products can be categorized by PC value into high-value products, value-added products, biocommodity, and products for public good. The PC value is a key indicator for evaluating the technological capability and economic viability of biomanufactured products. It is simple, transparent, and publicly accessible, offering a new approach for categorizing biomanufactured products. This indicator aids in guiding new technologies towards pathways of efficiency enhancement and cost reduction, forecasting future manufacturing costs and market prices for bioproducts, and assessing the industrialization potential of emerging biotechnologies. This article focuses on the biomanufacturing of fructose syrup, fructose solution, crystalline fructose, allulose, myo-inositol, and tagatose as examples, analyzing pathways for developing new technologies and predicting their economic feasibility. The calculation and analysis of the PC value could provide a new methodological tool for the top-level strategic design of the future development of emerging biomanufacturing industries, and could effectively facilitate the high-quality development of the bioeconomy.

Table 2

Speculations on future manufacturing technologies and costs for biocommodity

Extracts from the Article

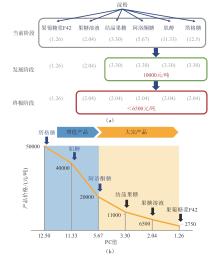

关于增效技术,以淀粉为原料生产果葡糖浆F42(70%)、果糖溶液、结晶果糖、阿洛酮糖、肌醇以及塔格糖为例,它们都是葡萄糖的同分异构体。目前,果葡糖浆F42(70%)、果糖溶液、结晶果糖、阿洛酮糖、肌醇以及塔格糖的价格约为每吨2750元、6500元、11000元、20000元、40000元、50000元,对应PC值分别是1.26、2.04、3.30、5.67、11.33、12.50(表2)。果葡糖浆F42(70%)、果糖溶液、结晶果糖属于低PC值的大宗产品,制造工艺十分完善,增效技术空间有限,价格利润空间很小;阿洛酮糖、肌醇以及塔格糖则属于增值产品,其增效潜力十分乐观。阿洛酮糖、肌醇和塔格糖具有广泛的应用场景,市场规模的增长潜力足以支持市场价格持续下探,随着制造技术持续进步,这些产品有望从增值产品转型为大宗产品。我们猜测,阿洛酮糖、肌醇和塔格糖的市场达到结晶果糖发展阶段时(PC= 3.30),价格能够降低到10000元/吨以下;发展到果糖溶液的成熟阶段时(PC = 2.04),终极价格甚至能降到6500元/吨以下(图2和表2)。

降本技术可能颠覆增效技术已经近乎完美的产品,具体包括廉价原料的替换、产品得率的提升等方式。以塔格糖生物制造技术发展历程为例:1992年,卡夫食品有限公司(Kraft Foods Inc.)首次提出了以半乳糖为原料,通过阿拉伯糖异构酶催化异构生产塔格糖[12],但由于原料价格昂贵,塔格糖市场价格居高不下;2013年,三养集团(Samyang Corp.)开发了以果糖为原料,通过果糖4-差向异构酶催化异构生产塔格糖的方法[13];2015年,作者提出以淀粉或其衍生物作为底物,经多酶级联催化方法制备塔格糖的体外多酶分子机器合成途径[14]。目前,塔格糖市场价格约5万元/吨,乳糖、果糖、淀粉的原料价格分别为12000元/吨、11000元/吨、3000元/吨,乳糖制塔格糖PC值为2.86,技术已基本成熟,降价空间很小;果糖制塔格糖的理论PC值最高7.69,淀粉制塔格糖目前PC值为12.5(表2),显然这两个新兴技术发展潜力较大,具有明显的市场价格竞争力,目前已成为生物制造投资领域关注的热点。

Other Images/Table from this Article

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||