|

||

|

Price to Cost-of-raw-materials Ratio (PC) of biomanufacturing: definition and application

Synthetic Biology Journal

2025, 6 (1):

8-17.

DOI: 10.12211/2096-8280.2024-072

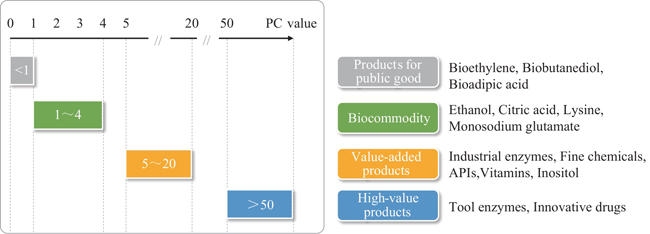

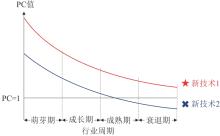

Biomanufacturing is one of the strategic emerging industries in China during the “14th Five-Year Plan” period. The author once proposed “Tao-Fa-Shu-Qi” for the industrial biomanufacturing and provided its philosophical guideline. Focusing on the “Fa” of biological manufacturing and further analyzing the concept of “Fa as rules” in biomanufacturing, the author first proposed the concept of “Price to Cost-of-raw-materials Ratio” (PC value), which is the ratio of product market price to cost with raw materials. Biomanufactured products can be categorized by PC value into high-value products, value-added products, biocommodity, and products for public good. The PC value is a key indicator for evaluating the technological capability and economic viability of biomanufactured products. It is simple, transparent, and publicly accessible, offering a new approach for categorizing biomanufactured products. This indicator aids in guiding new technologies towards pathways of efficiency enhancement and cost reduction, forecasting future manufacturing costs and market prices for bioproducts, and assessing the industrialization potential of emerging biotechnologies. This article focuses on the biomanufacturing of fructose syrup, fructose solution, crystalline fructose, allulose, myo-inositol, and tagatose as examples, analyzing pathways for developing new technologies and predicting their economic feasibility. The calculation and analysis of the PC value could provide a new methodological tool for the top-level strategic design of the future development of emerging biomanufacturing industries, and could effectively facilitate the high-quality development of the bioeconomy.

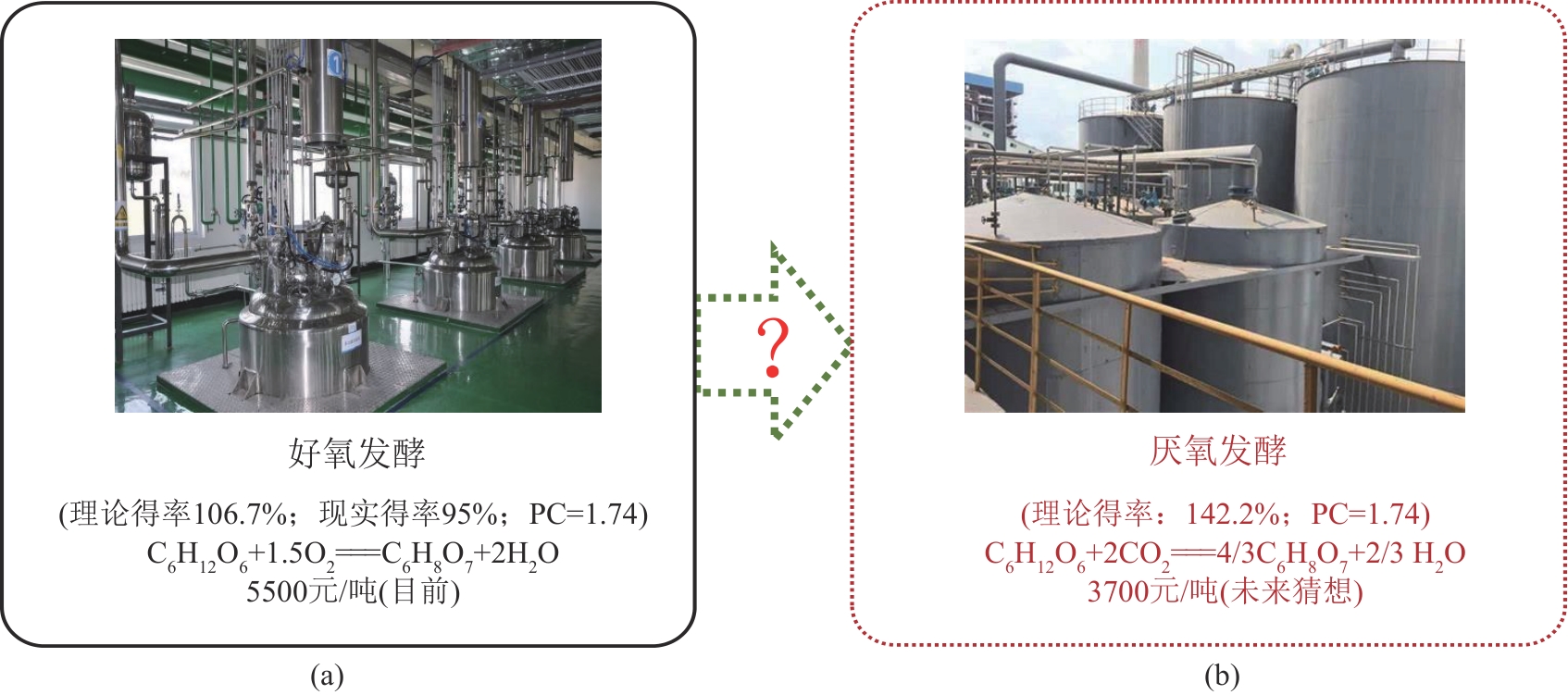

Fig. 3

Comparison of citric acid production with current production method (aerobic fermentation) (a) and hypothetical production method (anaerobic carbon fixation fermentation) (b) and their estimated manufacturing costs

Extracts from the Article

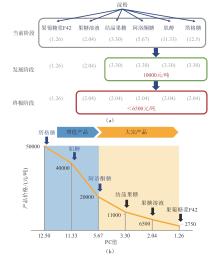

以有百年发酵历史的柠檬酸发酵为例。第一次世界大战阻止了意大利的柠檬出口,科学家开始研究霉菌发酵生产柠檬酸,其中黑曲霉的产酸能力最强。1923年,美国辉瑞公司建造了世界上第一家以黑曲霉浅盘发酵法生产柠檬酸的工厂,柠檬酸发酵法从此在产业上逐渐替代柑橘提取法。1952年,美国公司进一步开发深层好氧发酵法(类似青霉素发酵新方法)生产柠檬酸,发酵周期短、产率高、占地面积小,再次改变了柠檬酸的产业格局。目前,以淀粉为原料,深层好氧发酵法生产柠檬酸仍是最好的生物制造办法,理论得率是106.7%(即1 mol葡萄糖生产1 mol柠檬酸),考虑到合成其他杂酸与菌体生长消耗因素,实际得率约为95%,柠檬酸PC值是1.74[图3(a)],好氧发酵及产品分离制备工艺几乎接近完美,增效空间有限。

作者创新性地提出了一种柠檬酸生物合成的新方法——厌氧固碳发酵技术。该方法利用3 mol葡萄糖和6 mol二氧化碳,经过一系列生化反应,最后合成4 mol柠檬酸,理论得率可以提升至142%,PC值为2.6,相较现有水平提升了49%。在当前市场的产品价格体系下,这一技术有望显著提升利润空间。即便面对行业竞争加剧,PC值可能再度下探至1.74,柠檬酸市场价格降低到约3700元/吨[图3(b)],仍可维持合理利润。厌氧固碳发酵技术可能彻底颠覆现有柠檬酸生物制造产业,引领行业向更高效、更经济、更环保的生产方式迈进。

Other Images/Table from this Article

|