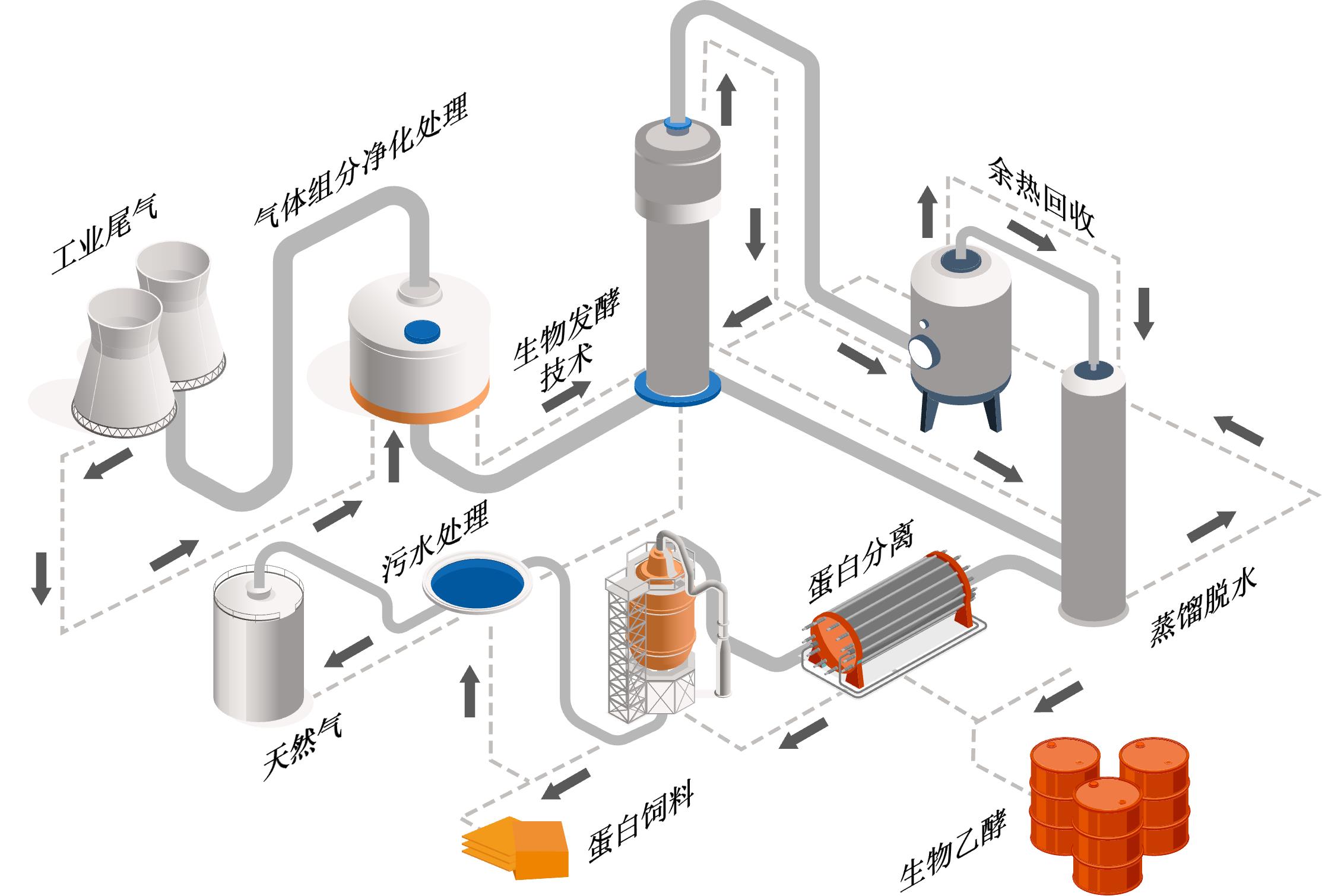

Research on the equipment, process, and commercialization progress of syngas fermentation

Xue BAI1, Nan LIANG1, Xinqi LI1, Zhipeng MO1, Shuhuan TONG1, Meiqi YUE1, Xiaojing JIA1, Kang REN1, Xiaojie XI2, Wei CHAO1

- 1.Beijing Shougang LangzaTech Technology Co. ,Ltd,Beijing 100049,China

2.Hebei Shoulang New Energy Technology Co. ,Ltd,Tangshan 063200,Hebei,China

-

Received:2025-01-02Revised:2025-02-21Published:2025-02-24 -

Contact:Wei CHAO

合成气发酵装备、工艺及商业化进展研究

白雪1, 梁楠1, 李欣启1, 莫志朋1, 佟淑环1, 岳美琪1, 贾晓静1, 任康1, 息晓杰2, 晁伟1

- 1.北京首钢朗泽科技股份有限公司,北京 100043

2.河北首朗新能源科技有限公司,河北 唐山 063200

-

通讯作者:晁伟 -

作者简介:白雪 (1989—),女,博士。研究方向为乙醇梭菌的遗传改造与代谢工程,并开发适用于乙醇梭菌筛选的高通量设备及方法,促进其工业化应用。E-mail:baixue@sgltne.com晁伟 (1982—),男,博士,高级工程师。研究方向为工业尾气生物转化制乙醇、蛋白和产业化应用。E-mail:chaowei@sgltne.com -

基金资助:国家重点研发计划(2024YFA0918100)

CLC Number:

Cite this article

Xue BAI, Nan LIANG, Xinqi LI, Zhipeng MO, Shuhuan TONG, Meiqi YUE, Xiaojing JIA, Kang REN, Xiaojie XI, Wei CHAO. Research on the equipment, process, and commercialization progress of syngas fermentation[J]. Synthetic Biology Journal, DOI: 10.12211/2096-8280.2025-001.

白雪, 梁楠, 李欣启, 莫志朋, 佟淑环, 岳美琪, 贾晓静, 任康, 息晓杰, 晁伟. 合成气发酵装备、工艺及商业化进展研究[J]. 合成生物学, DOI: 10.12211/2096-8280.2025-001.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: https://synbioj.cip.com.cn/EN/10.12211/2096-8280.2025-001

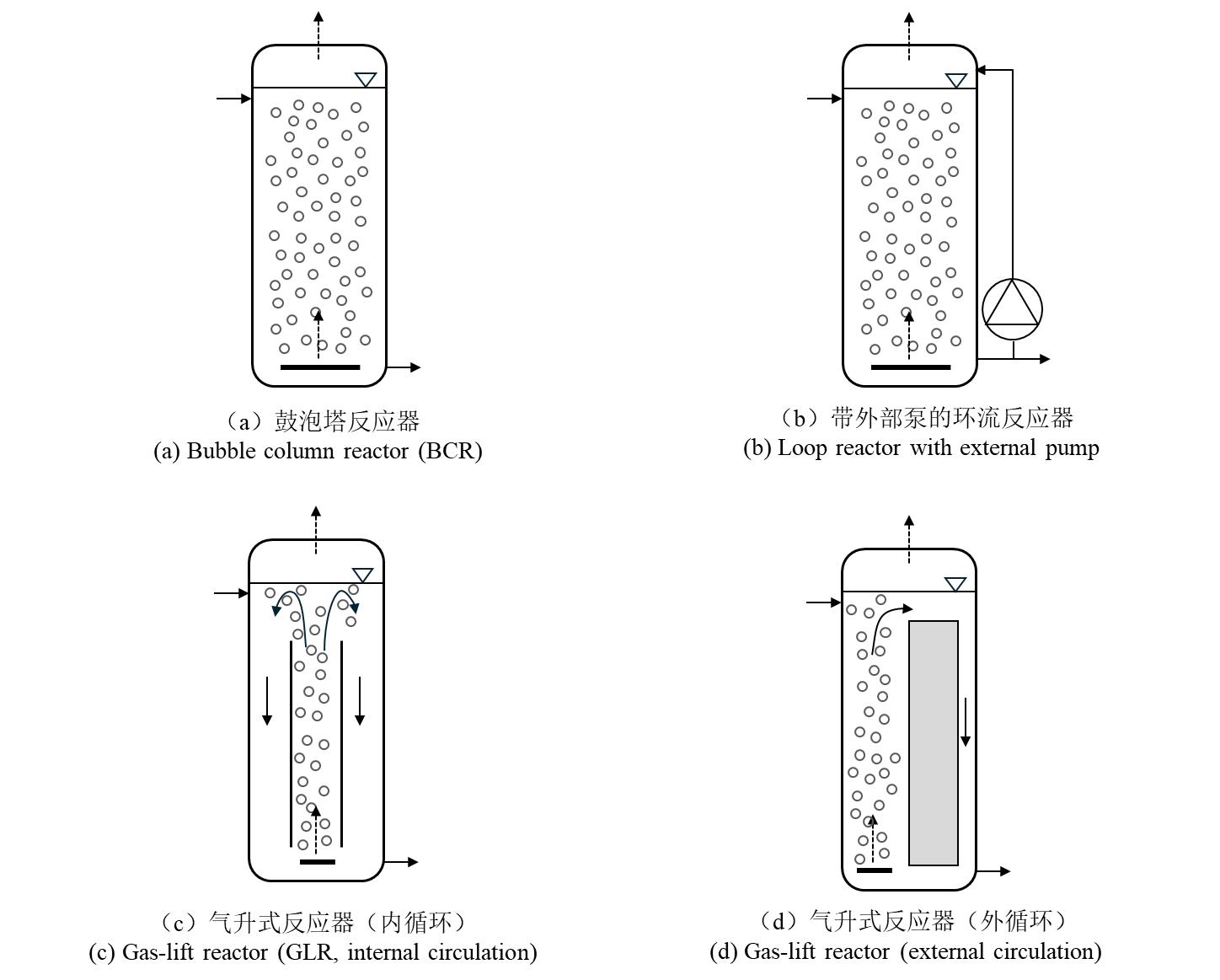

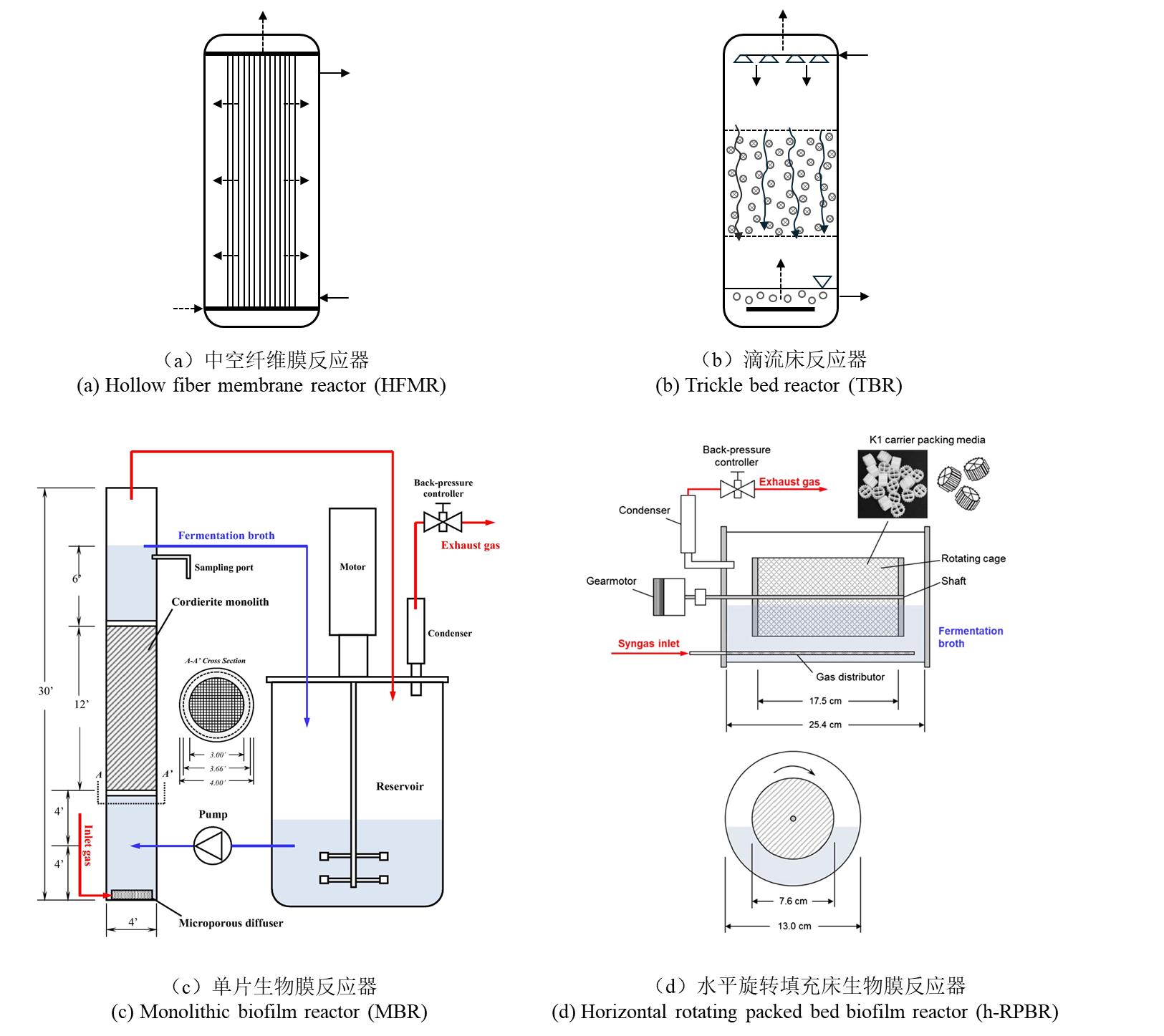

| 反应器类型 | 菌种 | 底物 | KLa(h-1) | 产物(g/L) | |

|---|---|---|---|---|---|

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇 1.17 丁醇0.56[ | |

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2,H2 | 未报道 | 乙醇 1.3 丁醇 0.5[ | |

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇 1.15 丁醇 0.74[ | |

| 鼓泡塔反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇0.16 wt% 乙酸0.03 wt% 丁醇0.11 wt%[ | |

| 鼓泡塔反应器 | M. thermoacetica | CO,CO2,H2 | 未报道 | 乙酸 32.3[ | |

| 气升式反应器 | C. carboxidivorans | CO,CO2 | 23.8-153.6(CO) 19.0-122.2(H2) | 乙醇 1.5丁醇 0.5[ | |

| 膜反应器 | Clostridium ragsdale | CO | 未报道 | 乙醇 1.4 乙酸 0.2[ | |

| 中空纤维膜反应器 | Eubacterium limosum | CO | 63.72-135.72(CO) | 乙酸 1.8[ | |

| 中空纤维膜反应器 | C. carboxidivorans | CO,CO2,H2 | 400-1096.2(CO) | 乙醇 23.93[ | |

| 滴流床反应器 | C. ragsdalei | CO,CO2,H2 | 未报道 | 乙醇 13.2 [ | |

| 单片生物膜反应器 | C. carboxidivorans | CO,CO2,H2 | 50-450(CO) | 乙醇 4.89 乙酸 2.35[ | |

| 水平旋转填充床反应器 | C. carboxidivorans | CO,CO2,H2 | 10-70(CO) | 乙醇 7.0[ | |

Table 1 Reactors applied to syngas fermentation and their fermentation performance

| 反应器类型 | 菌种 | 底物 | KLa(h-1) | 产物(g/L) | |

|---|---|---|---|---|---|

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇 1.17 丁醇0.56[ | |

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2,H2 | 未报道 | 乙醇 1.3 丁醇 0.5[ | |

| 连续搅拌反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇 1.15 丁醇 0.74[ | |

| 鼓泡塔反应器 | C. carboxidivorans | CO,CO2 | 未报道 | 乙醇0.16 wt% 乙酸0.03 wt% 丁醇0.11 wt%[ | |

| 鼓泡塔反应器 | M. thermoacetica | CO,CO2,H2 | 未报道 | 乙酸 32.3[ | |

| 气升式反应器 | C. carboxidivorans | CO,CO2 | 23.8-153.6(CO) 19.0-122.2(H2) | 乙醇 1.5丁醇 0.5[ | |

| 膜反应器 | Clostridium ragsdale | CO | 未报道 | 乙醇 1.4 乙酸 0.2[ | |

| 中空纤维膜反应器 | Eubacterium limosum | CO | 63.72-135.72(CO) | 乙酸 1.8[ | |

| 中空纤维膜反应器 | C. carboxidivorans | CO,CO2,H2 | 400-1096.2(CO) | 乙醇 23.93[ | |

| 滴流床反应器 | C. ragsdalei | CO,CO2,H2 | 未报道 | 乙醇 13.2 [ | |

| 单片生物膜反应器 | C. carboxidivorans | CO,CO2,H2 | 50-450(CO) | 乙醇 4.89 乙酸 2.35[ | |

| 水平旋转填充床反应器 | C. carboxidivorans | CO,CO2,H2 | 10-70(CO) | 乙醇 7.0[ | |

Fig. 4 Different reactor types(The schematic diagram (a) and (b) of reactor is reproduced from reference [67], the schematic diagram (c) and (d) of reactor is reproduced from references [65] and [66], respectively)

| 93 | HURST K M, LEWIS R S. Carbon monoxide partial pressure effects on the metabolic process of syngas fermentation[J]. Biochemical Engineering Journal, 2010, 48(2): 159-165. |

| 94 | OSWALD F, STOLL I K, ZWICK M, et al. Formic acid formation by Clostridium ljungdahlii at elevated pressures of carbon dioxide and hydrogen[J]. Frontiers in Bioengineering and Biotechnology, 2018, 6: 6. |

| 95 | MAKSIMOV P, LAARI A, RUUSKANEN V, et al. Gas phase methanol synthesis with Raman spectroscopy for gas composition monitoring[J]. RSC Advances, 2020, 10(40): 23690-23701. |

| 96 | METCALFE G D, SMITH T W, HIPPLER M. On-line analysis and in situ pH monitoring of mixed acid fermentation by Escherichia coli using combined FTIR and Raman techniques[J]. Analytical and Bioanalytical Chemistry, 2020, 412(26): 7307-7319. |

| 97 | DANG J, WANG N, ATIYEH H K. Review of dissolved CO and H2 measurement methods for syngas fermentation[J]. Sensors, 2021, 21(6): 2165. |

| 98 | PUIMAN L, BENALCÁZAR E A, PICIOREANU C, et al. Downscaling industrial-scale syngas fermentation to simulate frequent and irregular dissolved gas concentration shocks[J]. Bioengineering, 2023, 10(5): 518. |

| 99 | RICHTER H, MARTIN M, ANGENENT L. A two-stage continuous fermentation system for conversion of syngas into ethanol[J]. Energies, 2013, 6(8): 3987-4000. |

| 100 | ROBLES-IGLESIAS R, NAVEIRA-PAZOS C, NICAUD J M, et al. Two-stage syngas fermentation into microbial oils and β-carotene with Clostridium carboxidivorans and engineered Yarrowia lipolytica [J]. Journal of CO2 Utilization, 2023, 76: 102593. |

| 101 | SIVALINGAM V, AHMADI V, BABAFEMI O, et al. Integrating syngas fermentation into a single-cell microbial electrosynthesis (MES) reactor[J]. Catalysts, 2020, 11(1): 40. |

| 102 | PU Y, WANG Y, WU G, et al. Tandem acidic CO2 electrolysis coupled with syngas fermentation: a two-stage process for producing medium-chain fatty acids[J]. Environmental Science & Technology, 2024, 58(17): 7445-7456. |

| 103 | VERBEECK K, GILDEMYN S, RABAEY K. Membrane electrolysis assisted gas fermentation for enhanced acetic acid production[J]. Frontiers in Energy Research, 2018, 6: 88. |

| 104 | KUTTASSERY F, KUMAGAI H, KAMATA R, et al. Supramolecular photocatalysts fixed on the inside of the polypyrrole layer in dye sensitized molecular photocathodes: application to photocatalytic CO2 reduction coupled with water oxidation [J]. Chemical Science, 2021, 12(39): 13216-13232. |

| 105 | VERMA P, STEWART D J, RAJA R. Recent advances in photocatalytic CO2 utilisation over multifunctional metal–organic frameworks[J]. Catalysts, 2020, 10(10): 1176. |

| 106 | JANKOVIĆ T, STRAATHOF A J J, MCGREGOR I R, et al. Bioethanol separation by a new pass-through distillation process[J]. Separation and Purification Technology, 2024, 336: 126292. |

| 107 | ZENTOU H, ABIDIN Z Z, YUNUS R, et al. Overview of alternative ethanol removal techniques for enhancing bioethanol recovery from fermentation broth[J]. Processes, 2019, 7(7): 458. |

| 108 | DEVI N B, PUGAZHENTHI G, PAKSHIRAJAN K. Synthetic biology approaches and bioseparations in syngas fermentation[J]. Trends in Biotechnology, 2025, 43(1): 111-130. |

| 109 | HUANG T Y, HO J S, GOH S, et al. Ethanol recovery from dilute aqueous solution by perstraction using supported ionic liquid membrane (SILM)[J]. Journal of Cleaner Production, 2021, 298: 126811. |

| 110 | DIMITRIJEVIĆ D, BÖSENHOFER M, HARASEK M. Liquid–liquid phase separation of two non-dissolving liquids—A mini review[J]. Processes, 2023, 11(4): 1145. |

| 111 | REDL S, SUKUMARA S, PLOEGER T, et al. Thermodynamics and economic feasibility of acetone production from syngas using the thermophilic production host Moorella thermoacetica [J]. Biotechnology for Biofuels, 2017, 10(1): 150. |

| 112 | JEAN A B, BROWN R C. Techno-economic analysis of gas fermentation for the production of single cell protein[J]. Environmental Science & Technology, 2024, 58(8): 3823-3829. |

| 113 | VLAEMINCK E, UITTERHAEGEN E, QUATAERT K, et al. Single-cell protein production from industrial off-gas through acetate: Techno-economic analysis for a coupled fermentation approach[J]. Fermentation, 2023, 9(8): 771. |

| 114 | ANEKWE I M S, NYEMBE N, NQAKALA L C, et al. Sustainable fuels: Lower alcohols perspective[J]. Environmental Progress & Sustainable Energy, 2023, 42(6). |

| 115 | KNITTEL C R, MEISELMAN B S, STOCK J H. The pass-through of rin prices to wholesale and retail fuels under the renewable fuel standard[J]. Journal of the Association of Environmental and Resource Economists, 2017, 4(4): 1081-1119. |

| 116 | EGGERT H, GREAKER M. Promoting second generation biofuels: does the first generation pave the road? [J]. Energies, 2014, 7(7): 4430-4445. |

| 117 | DANIELL J, KÖPKE M, SIMPSON S. Commercial biomass syngas fermentation[J]. Energies, 2012, 5(12): 5372-5417. |

| 118 | 巨鹏生物发展历史[EB/OL]. . |

| 119 | 塞纳达生物01[EB/OL]. . |

| 120 | 食气生化[EB/OL]. . |

| 121 | 郭姝媛, 王博, 于涛, 等. 微生物中一碳代谢网络构建的进展与挑战[J]. 合成生物学, 2022, 3(1): 116-137. |

| GUO S Y, WANG B, YU T, et al. Developing C1-based metabolic network in methylotrophy for biotransformation[J]. Synthetic Biology Journal, 2022, 3(1): 116-137. | |

| 122 | 禹伟, 高教琪, 周雍进. 一碳生物转化合成有机酸的研究进展[J]. 合成生物学, 2024, 5(5): 1169-1188. |

| YU W, GAO J Q, ZHOU Y J. Bioconversion of one carbon feedstocks for producing organic acids[J]. Synthetic Biology Journal, 2024, 5(5): 1169-1188. | |

| 123 | 赵亮, 李福利, 刘自勇, 等. 生物转化一碳化合物原料产油脂与单细胞蛋白研究进展[J]. 合成生物学, 2024, 5(6): 1300-1318. |

| ZHAO L, LI F L, LIU Z Y. Progress in biomanufacturing of lipids and single cell protein from one-carbon compounds[J]. Synthetic Biology Journal, 2024, 5(6): 1300-1318. | |

| 124 | 叶伟, 姜卫红, 顾阳. 二氧化碳微生物转化与体外酶催化体系研究进展[J]. 合成生物学, 2023, 4(6): 1223-1245. |

| YE W, JIANG W H, GU Y. Microbial conversion and in vitro enzymatic catalysis for carbon dioxide utilization: a review[J]. Synthetic Biology Journal, 2023, 4(6): 1223-1245. | |

| 1 | CHU H, HUANG Z, ZHANG Z, et al. Integration of carbon emission reduction policies and technologies: Research progress on carbon capture, utilization and storage technologies[J]. Separation and Purification Technology, 2024, 343: 127153. |

| 2 | DAVOODI S, AL-SHARGABI M, WOOD D A, et al. Review of technological progress in carbon dioxide capture, storage, and utilization[J]. Gas Science and Engineering, 2023, 117: 205070. |

| 3 | JATAIN I, DUBEY K K, SHARMA M, et al. Synthetic biology potential for carbon sequestration into biocommodities[J]. Journal of Cleaner Production, 2021, 323: 129176. |

| 4 | LIU X, LUO H, YU D, et al. Synthetic biology promotes the capture of CO2 to produce fatty acid derivatives in microbial cell factories[J]. Bioresources and Bioprocessing, 2022, 9(1): 124. |

| 5 | DELISI C, PATRINOS A, MACCRACKEN M, et al. The role of synthetic biology in atmospheric greenhouse gas reduction: prospects and challenges[J]. Biodesign Research, 2020, 2020: 1016207. |

| 6 | FACKLER N, HEIJSTRA B D, RASOR B J, et al. Stepping on the gas to a circular economy: Accelerating development of carbon-negative chemical production from gas fermentation[J]. Annual Review of Chemical and Biomolecular Engineering, 2021, 12(1): 1-32. |

| 7 | CALVO D C, LUNA H J, ARANGO J A, et al. Determining global trends in syngas fermentation research through a bibliometric analysis[J]. Journal of Environmental Management, 2022, 307: 114522. |

| 8 | RAGSDALE S W. Enzymology of the Wood–Ljungdahl pathway of acetogenesis[J]. Annals of the New York Academy of Sciences, 2008, 1125(1): 129-136. |

| 9 | LIEW F, HENSTRA A M, KӦPKE M, et al. Metabolic engineering of Clostridium autoethanogenum for selective alcohol production[J]. Metabolic Engineering, 2017, 40: 104-114. |

| 10 | LAUER I, PHILIPPS G, JENNEWEIN S. Metabolic engineering of Clostridium ljungdahlii for the production of hexanol and butanol from CO2 and H2 [J]. Microbial Cell Factories, 2022, 21(1): 85. |

| 11 | ARSLAN K, SCHOCH T, HÖFELE F, et al. Engineering Acetobacterium woodii for the production of isopropanol and acetone from carbon dioxide and hydrogen[J]. Biotechnology Journal, 2022, 17(5): e2100515. |

| 12 | MOON J, POEHLEIN A, DANIEL R, et al. Redirecting electron flow in Acetobacterium woodii enables growth on CO and improves growth on formate[J]. Nature Communications, 2024, 15(1): 5424. |

| 13 | JIA D, DENG W, HU P, et al. Thermophilic Moorella thermoacetica as a platform microorganism for C1 gas utilization: Physiology, engineering, and applications[J]. Bioresources and Bioprocessing, 2023, 10(1): 61. |

| 14 | SUN X, ATIYEH H K, HUHNKE R L, et al. Syngas fermentation process development for production of biofuels and chemicals: A review[J]. Bioresource Technology Reports, 2019, 7: 100279. |

| 15 | BENEVENUTI C, AMARAL P, FERREIRA T, et al. Impacts of syngas composition on anaerobic fermentation[J]. Reactions, 2021, 2(4): 391-407. |

| 16 | MUNASINGHE P C, KHANAL S K. Biomass-derived syngas fermentation into biofuels: Opportunities and challenges[J]. Bioresource Technology, 2010, 101(13): 5013-5022. |

| 17 | OWOADE A, ALSHAMI A S, LEVIN D, et al. Progress and development of syngas fermentation processes toward commercial bioethanol production[J]. Biofuels, Bioproducts and Biorefining, 2023, 17(5): 1328-1342. |

| 18 | BALEEIRO F C F, KLEINSTEUBER S, NEUMANN A, et al. Syngas-aided anaerobic fermentation for medium-chain carboxylate and alcohol production: The case for microbial communities[J]. Applied Microbiology and Biotechnology, 2019, 103(21-22): 8689-8709. |

| 19 | MOLITOR B, MARCELLIN E, ANGENENT L T. Overcoming the energetic limitations of syngas fermentation[J]. Current Opinion in Chemical Biology, 2017, 41: 84-92. |

| 20 | BENGELSDORF F R, STRAUB M, DÜRRE P. Bacterial synthesis gas (syngas) fermentation[J]. Environmental Technology, 2013, 34(13-16): 1639-1651. |

| 21 | NETO A S, WAINAINA S, CHANDOLIAS K, et al. Exploring the potential of syngas fermentation for recovery of high-value resources: A comprehensive review[J]. Current Pollution Reports, 2024, 11(1): 7. |

| 22 | WAINAINA S, HORVÁTH I S, TAHERZADEH M J. Biochemicals from food waste and recalcitrant biomass via syngas fermentation: A review[J]. Bioresource Technology, 2018, 248(Pt A): 113-121. |

| 23 | KIM J Y, LEE M, OH S, et al. Acetogen and acetogenesis for biological syngas valorization[J]. Bioresource Technology, 2023, 384: 129368. |

| 24 | LEE J. Lessons from clostridial genetics: Toward engineering acetogenic bacteria[J]. Biotechnology and Bioprocess Engineering, 2021, 26(6): 841-858. |

| 25 | ENRIQUEZ F A, AHRING B K. Strategies to overcome mass transfer limitations of hydrogen during anaerobic gaseous fermentations: A comprehensive review[J]. Bioresource Technology, 2023, 377: 128948. |

| 26 | PUIMAN L, ELISIÁRIO M P, CRASBORN L M L, et al. Gas mass transfer in syngas fermentation broths is enhanced by ethanol[J]. Biochemical Engineering Journal, 2022, 185: 108505. |

| 27 | YOU M, ZHAO Q, LIU Y, et al. Insights into lignocellulose degradation: Comparative genomics of anaerobic and cellulolytic ruminiclostridium-type species[J]. Frontiers in Microbiology, 2023, 14: 1288286. |

| 28 | STARK C, MÜNSSINGER S, ROSENAU F, et al. The potential of sequential fermentations in converting C1 substrates to higher-value products[J]. Frontiers in Microbiology, 2022, 13: 907577. |

| 29 | WHITE H, HUBER C, FEICHT R, et al. On a reversible molybdenum-containing aldehyde oxidoreductase from Clostridium formicoaceticum [J]. Archives of Microbiology, 1993, 159(3): 244-249. |

| 30 | FAST A G, PAPOUTSAKIS E T. Stoichiometric and energetic analyses of non-photosynthetic CO2-fixation pathways to support synthetic biology strategies for production of fuels and chemicals[J]. Current Opinion in Chemical Engineering, 2012, 1(4): 380-395. |

| 31 | YAMAMOTO I, SAIKI T, LIU S M, et al. Purification and properties of NADP-dependent formate dehydrogenase from Clostridium thermoaceticum, a tungsten-selenium-iron protein[J]. Journal of Biological Chemistry, 1983, 258(3): 1826-1832. |

| 32 | MOON M, PARK G W, LEE J P, et al. Recombinant expression and characterization of formate dehydrogenase from Clostridium ljungdahlii (ClFDH) as CO2 reductase for converting CO2 to formate[J]. Journal of CO2 Utilization, 2022, 57: 101876. |

| 33 | NAGARAJU S, DAVIES N K, WALKER D J F, et al. Genome editing of Clostridium autoethanogenum using CRISPR/Cas9[J]. Biotechnology for Biofuels, 2016, 9(1): 219. |

| 34 | FACKLER N, HEFFERNAN J, JUMINAGA A, et al. Transcriptional control of Clostridium autoethanogenum using CRISPRi[J]. Synthetic Biology, 2021, 6(1): ysab008. |

| 35 | POULALIER-DELAVELLE M, BAKER J P, MILLARD J, et al. Endogenous CRISPR/Cas systems for genome engineering in the acetogens Acetobacterium woodii and Clostridium autoethanogenum [J]. Frontiers in Bioengineering and Biotechnology, 2023, 11: 1213236. |

| 36 | CHARUBIN K, STREETT H, PAPOUTSAKIS E T. Development of strong anaerobic fluorescent reporters for Clostridium acetobutylicum and Clostridium ljungdahlii using HaloTag and SNAP-tag proteins[J]. Applied and Environmental Microbiology, 2020, 86(20): e01271-20. |

| 37 | STREETT H E, KALIS K M, PAPOUTSAKIS E T. A Strongly fluorescing anaerobic reporter and protein-tagging system for Clostridium organisms based on the fluorescence-activating and absorption-shifting tag protein (FAST)[J]. Applied and Environmental Microbiology, 2019, 85(14): e00622-19. |

| 38 | KWON K K, LEE J, KIM H, et al. Advancing high-throughput screening systems for synthetic biology and biofoundry[J]. Current Opinion in Systems Biology, 2024, 37: 100487. |

| 39 | ZENG W, GUO L, XU S, et al. High-throughput screening technology in industrial biotechnology[J]. Trends in Biotechnology, 2020, 38(8): 888-906. |

| 40 | WANG Y, LI S, XUE N, et al. Modulating sensitivity of an erythromycin biosensor for precise high-throughput screening of strains with different characteristics[J]. ACS Synthetic Biology, 2023, 12(6): 1761-1771. |

| 41 | WONG B G, MANCUSO C P, KIRIAKOV S, et al. Precise, automated control of conditions for high-throughput growth of yeast and bacteria with eVOLVER[J]. Nature Biotechnology, 2018, 36(7): 614-623. |

| 42 | SUNDSTROM E R, CRIDDLE C S. Optimization of methanotrophic growth and production of poly(3-hydroxybutyrate) in a high-throughput microbioreactor system[J]. Applied and Environmental Microbiology, 2015, 81(14): 4767-4773. |

| 43 | KÖPKE M, SIMPSON S D. Pollution to products: recycling of 'above ground' carbon by gas fermentation[J]. Current Opinion in Biotechnology, 2020, 65: 180-189. |

| 44 | TU R, ZHANG Y, HUA E, et al. Droplet-based microfluidic platform for high-throughput screening of Streptomyces [J]. Communications Biology, 2021, 4(1): 647. |

| 45 | CHAO R, MISHRA S, SI T, et al. Engineering biological systems using automated biofoundries[J]. Metabolic Engineering, 2017, 42: 98-108. |

| 46 | MUNASINGHE P C, KHANAL S K. Syngas fermentation to biofuel: Evaluation of carbon monoxide mass transfer coefficient (KLa) in different reactor configurations[J]. Biotechnology Progress, 2010, 26(6): 1616-1621. |

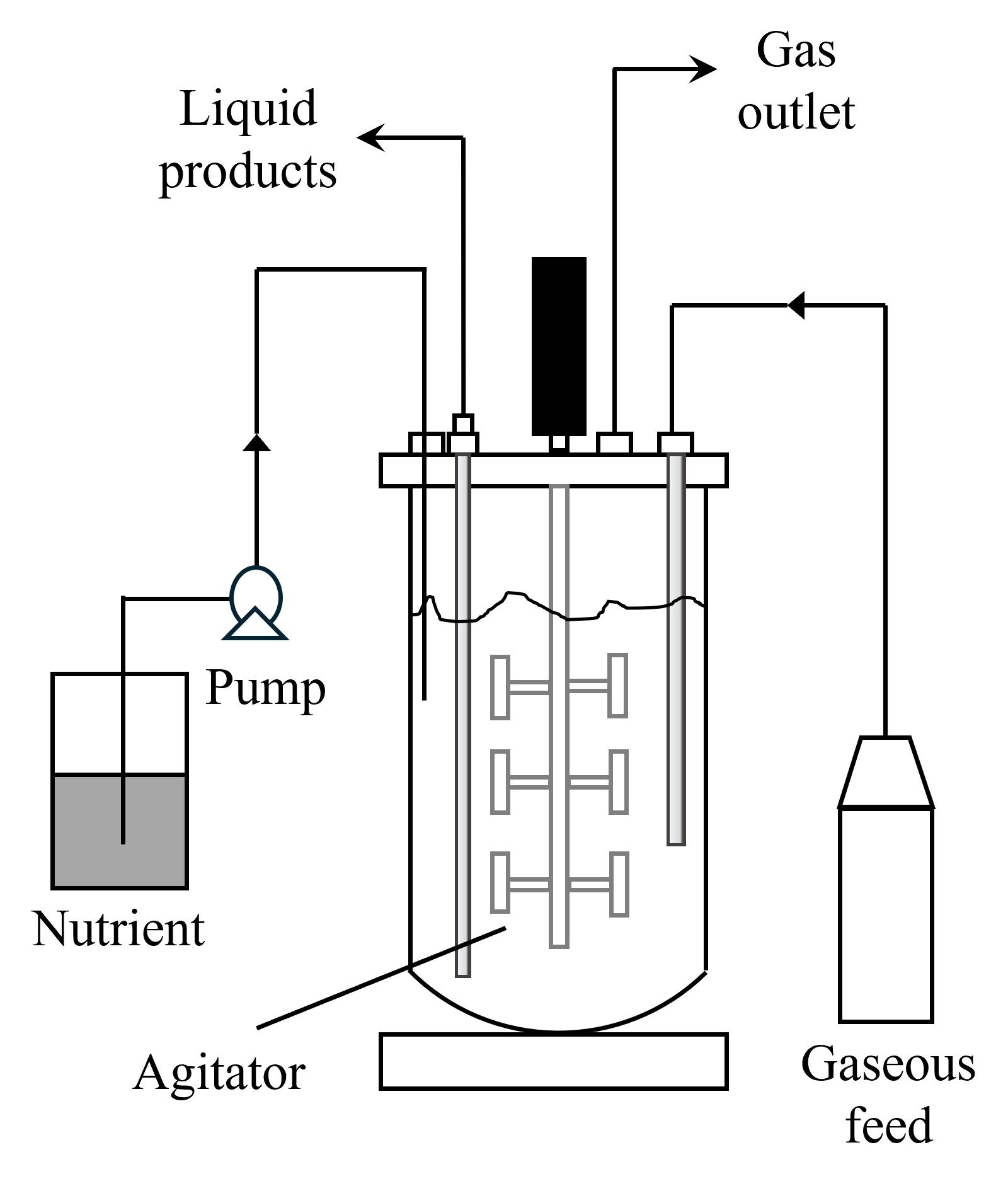

| 47 | UNGERMAN A J, HEINDEL T J. Carbon monoxide mass transfer for syngas fermentation in a stirred tank reactor with dual impeller configurations[J]. Biotechnology Progress, 2007, 23(3): 613-620. |

| 48 | ASIMAKOPOULOS K, GAVALA H N, SKIADAS I V. Reactor systems for syngas fermentation processes: A review[J]. Chemical Engineering Journal, 2018, 348: 732-744. |

| 49 | RIGGS S S, HEINDEL T J. Measuring carbon monoxide gas—liquid mass transfer in a stirred tank reactor for syngas fermentation[J]. Biotechnology Progress, 2006, 22(3): 903-906. |

| 50 | BREDWELL, SRIVASTAVA, WORDEN. Reactor design issues for synthesis-gas fermentations[J]. Biotechnology Progress, 1999, 15(5): 834-844. |

| 51 | ABUBACKAR H N, VEIGA M C, KENNES C. Biological conversion of carbon monoxide: Rich syngas or waste gases to bioethanol[J]. Biofuels, Bioproducts and Biorefining, 2011, 5(1): 93-114. |

| 52 | KANTARCI N, BORAK F, ULGEN K O. Bubble column reactors[J]. Process Biochemistry, 2005, 40(7): 2263-2283. |

| 53 | RAJAGOPALAN S, DATAR R P, LEWIS R S. Formation of ethanol from carbon monoxide via a new microbial catalyst[J]. Biomass and Bioenergy, 2002, 23(6): 487-493. |

| 54 | XU X, ZHANG Y. Hydrodynamics and mass transfer in an airlift loop reactor: Comparison between using two kinds of spargers[J]. Processes, 2023, 12(1): 35. |

| 55 | KOMMAREDDY A, ANDERSON G. Analysis of currents and mixing in a modified bubble column reactor[J]. 2004, Ottawa, Canada August 1 - 4, 2004, 2004. |

| 56 | FADAVI A, CHISTI Y. Gas–liquid mass transfer in a novel forced circulation loop reactor[J]. Chemical Engineering Journal, 2005, 112(1-3): 73-80. |

| 57 | RÜCKEL A, HANNEMANN J, MAIERHOFER C, et al. Studies on syngas fermentation with Clostridium carboxidivorans in stirred-tank reactors with defined gas impurities[J]. Frontiers in Microbiology, 2021, 12: 655390. |

| 58 | RÜCKEL A, OPPELT A, LEUTER P, et al. Conversion of syngas from entrained flow gasification of biogenic residues with Clostridium carboxidivorans and Clostridium autoethanogenum [J]. Fermentation, 2022, 8(9): 465. |

| 59 | RIEGLER P, CHRUSCIEL T, MAYER A, et al. Reversible retrofitting of a stirred-tank bioreactor for gas-lift operation to perform synthesis gas fermentation studies[J]. Biochemical Engineering Journal, 2019, 141: 89-101. |

| 60 | ZHANG L, HU P, PAN J, et al. Immobilization of trophic anaerobic acetogen for semi-continuous syngas fermentation[J]. Chinese Journal of Chemical Engineering, 2021, 29: 311-316. |

| 61 | SERTKAYA S, GUNDOGDU T K, KENNES C, et al. Bioethanol production through syngas fermentation by a novel immobilized bioreactor using Clostridium ragsdalei [J]. Icontech International Journal, 2021, 5(3): 13-20. |

| 62 | YASIN M, PARK S, JEONG Y, et al. Effect of internal pressure and gas/liquid interface area on the CO mass transfer coefficient using hollow fibre membranes as a high mass transfer gas diffusing system for microbial syngas fermentation[J]. Bioresource Technology, 2014, 169: 637-643. |

| 63 | SHEN Y, BROWN R, WEN Z. Syngas fermentation of Clostridium carboxidivoran P7 in a hollow fiber membrane biofilm reactor: Evaluating the mass transfer coefficient and ethanol production performance[J]. Biochemical Engineering Journal, 2014, 85: 21-29. |

| 64 | DEVARAPALLI M, LEWIS R S, ATIYEH H K. Continuous ethanol production from synthesis gas by Clostridium ragsdalei in a trickle-bed reactor[J]. Fermentation, 2017, 3(2): 23. |

| 65 | SHEN Y, BROWN R, WEN Z. Enhancing mass transfer and ethanol production in syngas fermentation of Clostridium carboxidivorans P7 through a monolithic biofilm reactor[J]. Applied Energy, 2014, 136: 68-76. |

| 66 | SHEN Y, BROWN R C, WEN Z. Syngas fermentation by Clostridium carboxidivorans P7 in a horizontal rotating packed bed biofilm reactor with enhanced ethanol production[J]. Applied Energy, 2017, 187: 585-594. |

| 67 | STOLL I K, BOUKIS N, SAUER J. Syngas fermentation to alcohols: Reactor technology and application perspective[J]. Chemie Ingenieur Technik, 2020, 92(1-2): 125-136. |

| 68 | CHEN J, GOMEZ J A, HÖFFNER K, et al. Metabolic modeling of synthesis gas fermentation in bubble column reactors[J]. Biotechnology for Biofuels, 2015, 8(1): 89. |

| 69 | BENALCÁZAR E A, NOORMAN H, FILHO R M, et al. Modeling ethanol production through gas fermentation: A biothermodynamics and mass transfer-based hybrid model for microbial growth in a large-scale bubble column bioreactor[J]. Biotechnology for Biofuels, 2020, 13(1): 59. |

| 70 | LEE M, YASIN M, JANG N, et al. A simultaneous gas feeding and cell-recycled reaction (SGCR) system to achieve biomass boosting and high acetate titer in microbial carbon monoxide fermentation[J]. Bioresource Technology, 2020, 298: 122549. |

| 71 | LEE P H, NI S Q, CHANG S Y, et al. Enhancement of carbon monoxide mass transfer using an innovative external hollow fiber membrane (HFM) diffuser for syngas fermentation: Experimental studies and model development[J]. Chemical Engineering Journal, 2012, 184: 268-277. |

| 72 | LU C, CHENG W, LI Z, et al. Influence of Aeration rates on oxygen mass transfer and flow- field in a microporous aeration system[J]. Polish Journal of Environmental Studies, 2021, 30(4): 3727-3739. |

| 73 | AHMED T, SEMMENS M J. Use of sealed end hollow fibers for bubbleless membrane aeration: experimental studies[J]. Journal of Membrane Science, 1992, 69(1-2): 1-10. |

| 74 | JENSEN M B, OTTOSEN L D M, KOFOED M V W. H2 gas-liquid mass transfer: A key element in biological Power-to-Gas methanation[J]. Renewable and Sustainable Energy Reviews, 2021, 147: 111209. |

| 75 | EBRAHIMI S, KLEEREBEZEM R, KREUTZER M T, et al. Potential application of monolith packed columns as bioreactors, control of biofilm formation[J]. Biotechnology and Bioengineering, 2006, 93(2): 238-245. |

| 76 | EBRAHIMI S, PICIOREANU C, XAVIER J B, et al. Biofilm growth pattern in honeycomb monolith packings: Effect of shear rate and substrate transport limitations[J]. Catalysis Today, 2005, 105(3-4): 448-454. |

| 77 | BEYGMOHAMMDI F, KAZEROUNI H N, JAFARZADEH Y, et al. Preparation and characterization of PVDF/PVP-GO membranes to be used in MBR system[J]. Chemical Engineering Research and Design, 2020, 154: 232-240. |

| 78 | DJAMEL G. New configurations and techniques for controlling membrane bioreactor (MBR) fouling[J]. Open Access Library Journal, 2020, 07(07): 1-18. |

| 79 | E M de MEDEIROS, NOORMAN H, FILHO R M, et al. Production of ethanol fuel via syngas fermentation: Optimization of economic performance and energy efficiency[J]. Chemical Engineering Science: X, 2020, 5: 100056. |

| 80 | TAKORS R, KOPF M, MAMPEL J, et al. Using gas mixtures of CO, CO2 and H2 as microbial substrates: The do's and don'ts of successful technology transfer from laboratory to production scale[J]. Microbial Biotechnology, 2018, 11(4): 606-625. |

| 81 | ELISIÁRIO M P, WEVER H D, HECKE W V, et al. Membrane bioreactors for syngas permeation and fermentation[J]. Critical Reviews in Biotechnology, 2022, 42(6): 856-872. |

| 82 | KURT E, QIN J, WILLIAMS A, et al. Perspectives for using CO2 as a feedstock for biomanufacturing of fuels and chemicals[J]. Bioengineering, 2023, 10(12): 1357. |

| 83 | OSWALD F, ZWICK M, OMAR O, et al. Growth and product formation of Clostridium ljungdahlii in presence of cyanide[J]. Frontiers in Microbiology, 2018, 9: 1213. |

| 84 | FRILUND C, KOTILAINEN M, LORENZO J B, et al. Steel manufacturing EAF dust as a potential adsorbent for hydrogen sulfide removal[J]. Energy & Fuels, 2022, 36(7): 3695-3703. |

| 85 | CILIBERTI C, BIUNDO A, ALBERGO R, et al. Syngas derived from lignocellulosic biomass gasification as an alternative resource for innovative bioprocesses[J]. Processes, 2020, 8(12): 1567. |

| 86 | LÓPEZ P A, REBECCHI S, VLAEMINCK E, et al. Demonstrating pilot-scale gas fermentation for acetate production from biomass-derived syngas streams[J]. Fermentation, 2024, 10(6): 285. |

| 87 | HARAHAP B M, AHRING B K. Acetate production from syngas produced from lignocellulosic biomass materials along with gaseous fermentation of the syngas: A review[J]. Microorganisms, 2023, 11(4): 995. |

| 88 | SAXENA J, TANNER R S. Optimization of a corn steep medium for production of ethanol from synthesis gas fermentation by Clostridium ragsdalei [J]. World Journal of Microbiology and Biotechnology, 2012, 28(4): 1553-1561. |

| 89 | ABUBACKAR H N, VEIGA M C, KENNES C. Carbon monoxide fermentation to ethanol by Clostridium autoethanogenum in a bioreactor with no accumulation of acetic acid[J]. Bioresource Technology, 2015, 186: 122-127. |

| 90 | LI D, MENG C, WU G, et al. Effects of zinc on the production of alcohol by Clostridium carboxidivorans P7 using model syngas[J]. Journal of Industrial Microbiology & Biotechnology, 2018, 45(1): 61-69. |

| 91 | SHEN S, WANG G, ZHANG M, et al. Effect of temperature and surfactant on biomass growth and higher-alcohol production during syngas fermentation by Clostridium carboxidivorans P7[J]. Bioresources and Bioprocessing, 2020, 7(1): 56. |

| 92 | LIU C, LUO G, WANG W, et al. The effects of pH and temperature on the acetate production and microbial community compositions by syngas fermentation[J]. Fuel, 2018, 224: 537-544. |

| [1] | Xiaojie GUO, Xingjin JIAN, Liyan WANG, Chong ZHANG, Xinhui XING. Progress in bioreactors and instruments for phenotype testing with synthetic biology research [J]. Synthetic Biology Journal, 2024, 5(1): 16-37. |

| [2] | Yujuan LI, Xiongfei FU, Li DU. Regulating the commercialization of cell-cultured meat: practices in selected jurisdictions and their implications for China [J]. Synthetic Biology Journal, 2022, 3(1): 209-223. |

| [3] | Zhiguo SU. Great impact of Professor Daniel I.C. Wang and BPEC on development of biochemical engineering [J]. Synthetic Biology Journal, 2021, 2(4): 470-481. |

| [4] | Li DU, Meng WANG. The legal issues about commercialization of food products employing synthetic biology strategies [J]. Synthetic Biology Journal, 2020, 1(5): 593-608. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||