Synthetic Biology Journal ›› 2024, Vol. 5 ›› Issue (6): 1461-1484.DOI: 10.12211/2096-8280.2024-052

• Invited Review • Previous Articles Next Articles

Studies on hydrogenases for hydrogen production using in vitro synthetic enzymatic biosystems

LI Yifei1,2,3,4, CHEN Ai1,2,3,4, SUN Junsong1,2, ZHANG Yi-Heng P. Job2,3,4,5

- 1.Low Carbon Biotransformation Group,Shanghai Advanced Research Institute,Chinese Academy of Sciences,Shanghai 201210,China

2.University of Chinese Academy of Sciences,Beijing 100049,China

3.Key Laboratory of Engineering Biology for Low-Carbon Manufacturing,Tianjin Institute of Industrial Biotechnology,Chinese Academy of Sciences,Tianjin 300308,China

4.In Vitro Synthetic Biology Center,Tianjin Institute of Industrial Biotechnology,Chinese Academy of Sciences,Tianjin 300308,China

5.Haihe Laboratory of Synthetic Biology,Tianjin 300308,China

-

Received:2024-07-09Revised:2024-09-25Online:2025-01-10Published:2024-12-31 -

Contact:SUN Junsong, ZHANG Yi-Heng P. Job

体外多酶分子机器产氢应用中的氢酶研究

李怡霏1,2,3,4, 陈艾1,2,3,4, 孙俊松1,2, 张以恒2,3,4,5

- 1.中国科学院上海高等研究院低碳生物转化团队,上海 201210

2.中国科学院大学,北京 100049

3.中国科学院天津工业生物技术研究所低碳合成工程生物学(全国)重点实验室,天津 300308

4.中国科学院天津工业生物技术研究所体外合成生物学中心,天津 300308

5.合成生物学海河实验室,天津 300308

-

通讯作者:孙俊松,张以恒 -

作者简介:李怡霏 (2000—),女,硕士研究生。研究方向为氢酶参与的体外多酶分子机器构建。 E-mail:liyf@sari.ac.cn孙俊松 (1974—),男,博士,研究员。研究方向为氢酶表达、微生物代谢改造及生物合成。 E-mail:sunjs@sari.ac.cn张以恒 (1971—),男,博士,研究员,中国科学院天津工业生物技术研究所低碳合成工程生物学(全国)重点实验室主任,曾任美国弗吉尼亚理工大学终身正教授。研究方向为体外合成生物学、新质生物制造、生物炼制和淀粉储能。 E-mail:zhang_xw@tib.cas.cn -

基金资助:国家重点研发计划“合成生物学”重点专项“糖水氢电系统——体外多酶高效产氢及氢电装置的基础及工程研究”(2022YFA0912000)

CLC Number:

Cite this article

LI Yifei, CHEN Ai, SUN Junsong, ZHANG Yi-Heng P. Job. Studies on hydrogenases for hydrogen production using in vitro synthetic enzymatic biosystems[J]. Synthetic Biology Journal, 2024, 5(6): 1461-1484.

李怡霏, 陈艾, 孙俊松, 张以恒. 体外多酶分子机器产氢应用中的氢酶研究[J]. 合成生物学, 2024, 5(6): 1461-1484.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: https://synbioj.cip.com.cn/EN/10.12211/2096-8280.2024-052

氢酶 Hydrogenase | 表达宿主 Expression host | 成熟蛋白 Maturation protein | 全细胞活性 Whole cell activity | 纯化酶活性 Purified enzyme activity | 参考文献 References |

|---|---|---|---|---|---|

| CacHydA | C. acetobutylicum | Host | NR | 162 ② | [ |

| CacHydA | E. coli | C. acetobutylicum | 96 ① | 75 ② | [ |

| CacHydA | E. coli ∆iscR | C. acetobutylicum | 1.3 ①,* | 96 ② | [ |

| CacHydA | S. elongatus | C. reinhardtii | NR | 0.05 ② | [ |

| CacHydB | E. coli | C. acetobutylicum | NR | 8.6 ② | [ |

| CbuHydA | E. coli | Host | 500 ① | NR | [ |

| CpaHydA | C. pasteurianum | Host | 1681 ① | 1236 ② | [ |

| CpaHydI | E. coli | S. oneidensis | NR | 1087 ② | [ |

| CpaHydI | Synechococcus sp. | Host | NR | 4.6 ② | [ |

| CreHydA1 | C. reinhardtii | Host | 13.8 ②,* | 741 ② | [ |

| CreHydA1 | C. acetobutylicum | Host | NR | 625~760 ② | [ |

| CreHydA1 | E. coli | C. reinhardtii | NR | 0.4 ② | [ |

| CreHydA1 | E. coli | C. acetobutylicum | 61 ① | 150 ② | [ |

| CreHydA1-Fd | E. coli | C. acetobutylicum | NR | 1000 ② | [ |

| CreHydA1 | E. coli | S. oneidensis | NR | 641 ② | [ |

| CreHydA1 | S. oneidensis | Host | NA | 740 ② | [ |

| CreHydA1 | Synechocystis sp. | Host | NR | 0.1 ② | [ |

| CreHydA2 | E. coli | C. acetobutylicum | 108 ① | 116 ② | [ |

| CsuHydA | E. coli | S. oneidensis | NA | 6.5 ② | [ |

| EhaHyd | E. coli | Host | NR | 70 ② | [ |

| EhiHyd | E. coli | Host | NR | 0.04 ② | [ |

| PgrHyd | E. coli | Host | NR | 2131 ② | [ |

| SobHydA1 | C. acetobutylicum | Host | NR | 633 ② | [ |

| SonHydA | Anabaena sp. | S. oneidensis | NR | 0.06 ② | [ |

Table 1 Recombinant [FeFe] hydrogenase activity

氢酶 Hydrogenase | 表达宿主 Expression host | 成熟蛋白 Maturation protein | 全细胞活性 Whole cell activity | 纯化酶活性 Purified enzyme activity | 参考文献 References |

|---|---|---|---|---|---|

| CacHydA | C. acetobutylicum | Host | NR | 162 ② | [ |

| CacHydA | E. coli | C. acetobutylicum | 96 ① | 75 ② | [ |

| CacHydA | E. coli ∆iscR | C. acetobutylicum | 1.3 ①,* | 96 ② | [ |

| CacHydA | S. elongatus | C. reinhardtii | NR | 0.05 ② | [ |

| CacHydB | E. coli | C. acetobutylicum | NR | 8.6 ② | [ |

| CbuHydA | E. coli | Host | 500 ① | NR | [ |

| CpaHydA | C. pasteurianum | Host | 1681 ① | 1236 ② | [ |

| CpaHydI | E. coli | S. oneidensis | NR | 1087 ② | [ |

| CpaHydI | Synechococcus sp. | Host | NR | 4.6 ② | [ |

| CreHydA1 | C. reinhardtii | Host | 13.8 ②,* | 741 ② | [ |

| CreHydA1 | C. acetobutylicum | Host | NR | 625~760 ② | [ |

| CreHydA1 | E. coli | C. reinhardtii | NR | 0.4 ② | [ |

| CreHydA1 | E. coli | C. acetobutylicum | 61 ① | 150 ② | [ |

| CreHydA1-Fd | E. coli | C. acetobutylicum | NR | 1000 ② | [ |

| CreHydA1 | E. coli | S. oneidensis | NR | 641 ② | [ |

| CreHydA1 | S. oneidensis | Host | NA | 740 ② | [ |

| CreHydA1 | Synechocystis sp. | Host | NR | 0.1 ② | [ |

| CreHydA2 | E. coli | C. acetobutylicum | 108 ① | 116 ② | [ |

| CsuHydA | E. coli | S. oneidensis | NA | 6.5 ② | [ |

| EhaHyd | E. coli | Host | NR | 70 ② | [ |

| EhiHyd | E. coli | Host | NR | 0.04 ② | [ |

| PgrHyd | E. coli | Host | NR | 2131 ② | [ |

| SobHydA1 | C. acetobutylicum | Host | NR | 633 ② | [ |

| SonHydA | Anabaena sp. | S. oneidensis | NR | 0.06 ② | [ |

氢酶 Hydrogenase | 表达宿主 Expression host | 成熟蛋白 Maturation protein | 全细胞活性 Whole cell activity | 纯化酶活性 Purified enzyme activity | 参考文献 References |

|---|---|---|---|---|---|

| AmaHynSL | A. macleodi ∆HynSL | Host | 0.03 ①,* | 0.1 ③ | [ |

| AmaHynSL | E. coli | A. macleodii | 3×10-3~70×10-3 ①,* | NR | [ |

| AmaHyaAB | T. roseopersicina | Host, A. macleodii | 5×10-3 ① | NR | [ |

| AflHydSL | E. coli | Host | NA | 77 ① | [ |

| DgiHynAB | D. gigas ∆HynAB | Host | 1.9 ①,* | 91 ① | [ |

| DgiHynAB | D. fructosovorans ∆HynAB | Host | 0.2 ② | NR | [ |

| EcoHyd1 | E. coli ∆Hyd1 | Host | 4×10-2~7×10-2 ①,* | 1×10-2~3×10-2 ① | [ |

| HmaMBH | E. coli | E. coli | 0.07 ①,* | 0.03 ① | [ |

| NpuHupSL | E. coli | E. coli | 208 ① | NR | [ |

| PfuSH | E. coli | P. furiosus | 2.9 ① | 100 ① | [ |

| PfuSHI | T. kodakarensis | Host | 23.6 ④ | 880 ④ | [ |

| ReuMBH | R. Eutropha H16 | Host | 1.0 ③,* | 170 ③ | [ |

| ReuMBH | P. stutzeri | R. eutropha | 17~19 ③,* | NR | [ |

| ReuRH | E. coli | R. eutropha | NR | 0.8 ② | [ |

| ReuRH | E. coli | R. eutropha | 1.2 ②,* | 230 ② | [ |

| RopSH | R. eutropha ∆SH ∆MBH | Host, R. opacus | 5.9 ①,* | NR | [ |

| SynSH | E. coli | Synechocystis sp. | 0.04 ①,* | NR | [ |

Table 2 The activities of the reported recombinant [NiFe] hydrogenases

氢酶 Hydrogenase | 表达宿主 Expression host | 成熟蛋白 Maturation protein | 全细胞活性 Whole cell activity | 纯化酶活性 Purified enzyme activity | 参考文献 References |

|---|---|---|---|---|---|

| AmaHynSL | A. macleodi ∆HynSL | Host | 0.03 ①,* | 0.1 ③ | [ |

| AmaHynSL | E. coli | A. macleodii | 3×10-3~70×10-3 ①,* | NR | [ |

| AmaHyaAB | T. roseopersicina | Host, A. macleodii | 5×10-3 ① | NR | [ |

| AflHydSL | E. coli | Host | NA | 77 ① | [ |

| DgiHynAB | D. gigas ∆HynAB | Host | 1.9 ①,* | 91 ① | [ |

| DgiHynAB | D. fructosovorans ∆HynAB | Host | 0.2 ② | NR | [ |

| EcoHyd1 | E. coli ∆Hyd1 | Host | 4×10-2~7×10-2 ①,* | 1×10-2~3×10-2 ① | [ |

| HmaMBH | E. coli | E. coli | 0.07 ①,* | 0.03 ① | [ |

| NpuHupSL | E. coli | E. coli | 208 ① | NR | [ |

| PfuSH | E. coli | P. furiosus | 2.9 ① | 100 ① | [ |

| PfuSHI | T. kodakarensis | Host | 23.6 ④ | 880 ④ | [ |

| ReuMBH | R. Eutropha H16 | Host | 1.0 ③,* | 170 ③ | [ |

| ReuMBH | P. stutzeri | R. eutropha | 17~19 ③,* | NR | [ |

| ReuRH | E. coli | R. eutropha | NR | 0.8 ② | [ |

| ReuRH | E. coli | R. eutropha | 1.2 ②,* | 230 ② | [ |

| RopSH | R. eutropha ∆SH ∆MBH | Host, R. opacus | 5.9 ①,* | NR | [ |

| SynSH | E. coli | Synechocystis sp. | 0.04 ①,* | NR | [ |

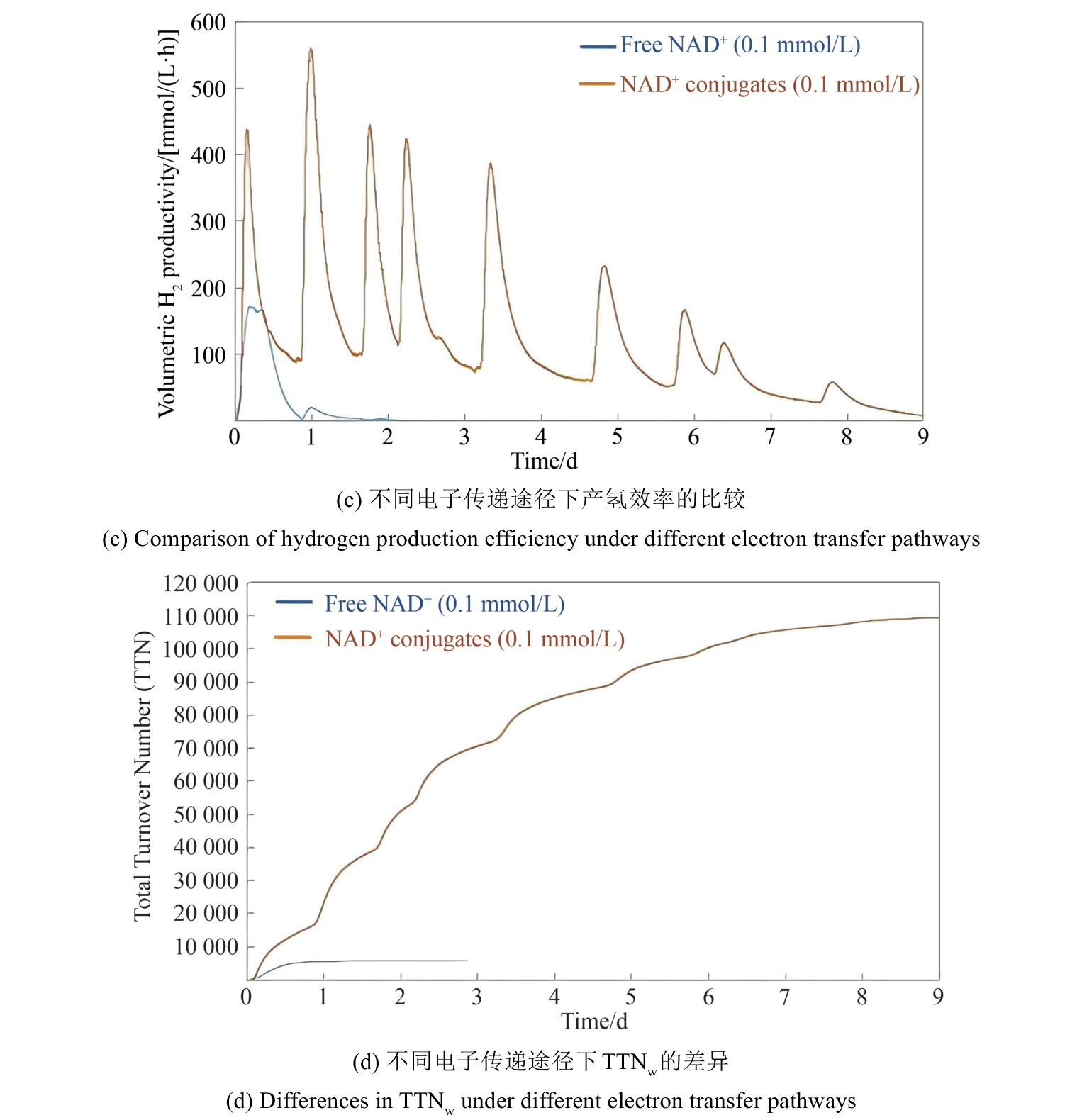

Fig. 6 The application of artificial electron coenzyme to improve the efficiency of electron transport in ivSEB system for hydrogen production(The impact of different artificial electron transfer pathways on the synthesis) G6PDH—Glucose 6-phosphate dehydrogenase; 6PGDH—6-phosphogluconate dehydrogenase; DI—diaphorase; SHⅠ—soluble hydrogenaseⅠ; BCV—the coupled benzyl viologen

| 1 | ARMAROLI N, BALZANI V. The hydrogen issue[J]. ChemSusChem, 2011, 4(1): 21-36. |

| 2 | NIKOLAIDIS P, POULLIKKAS A. A comparative overview of hydrogen production processes[J]. Renewable and Sustainable Energy Reviews, 2017, 67: 597-611. |

| 3 | MIDILLI A, KUCUK H, TOPAL M E, et al. A comprehensive review on hydrogen production from coal gasification: challenges and opportunities[J]. International Journal of Hydrogen Energy, 2021, 46(50): 25385-25412. |

| 4 | HAQ B, SALAHU MUHAMMED N, LIU J S, et al. Enhanced natural gas production using CO2 injection: application to sustainable hydrogen production[J]. Fuel, 2023, 347: 128474. |

| 5 | YANG K, GU Z H, LONG Y H, et al. Hydrogen production via chemical looping reforming of coke oven gas[J]. Green Energy & Environment, 2021, 6(5): 678-692. |

| 6 | ZHANG L N, LI R, ZANG H Y, et al. Advanced hydrogen evolution electrocatalysts promising sustainable hydrogen and chlor-alkali co-production[J]. Energy & Environmental Science, 2021, 14(12): 6191-6210. |

| 7 | NIBLETT D, DELPISHEH M, RAMAKRISHNAN S, et al. Review of next generation hydrogen production from offshore wind using water electrolysis[J]. Journal of Power Sources, 2024, 592: 233904. |

| 8 | WANG S, LU A L, ZHONG C J. Hydrogen production from water electrolysis: role of catalysts[J]. Nano Convergence, 2021, 8(1): 4. |

| 9 | BALAT H, KIRTAY E. Hydrogen from biomass - present scenario and future prospects[J]. International Journal of Hydrogen Energy, 2010, 35(14): 7416-7426. |

| 10 | KIM S H, KUMAR G, CHEN W H, et al. Renewable hydrogen production from biomass and wastes (ReBioH2-2020)[J]. Bioresource Technology, 2021, 331: 125024. |

| 11 | REDDING K E, APPEL J, BOEHM M, et al. Advances and challenges in photosynthetic hydrogen production[J]. Trends in Biotechnology, 2022, 40(11): 1393. |

| 12 | SRIRANGAN K, PYNE M E, CHOU C P. Biochemical and genetic engineering strategies to enhance hydrogen production in photosynthetic algae and cyanobacteria[J]. Bioresource Technology, 2011, 102(18): 8589-8604. |

| 13 | 张以恒. 中国哲学思想“道法术器”对生物制造的启示[J]. 合成生物学, 2023, 5(6):1231-1241. |

| ZHANG Y-H P J. The enlightenment of the Chinese philosophy “Tao-Fa-Shu-Qi” to industrial biomanufacturing [J]. Synthetic Biology Journal, 2023, 5(6):1231-1241. | |

| 14 | SAMBUSITI C, BELLUCCI M, ZABANIOTOU A, et al. Algae as promising feedstocks for fermentative biohydrogen production according to a biorefinery approach: a comprehensive review[J]. Renewable and Sustainable Energy Reviews, 2015, 44: 20-36. |

| 15 | ZHANG T, JIANG D P, ZHANG H, et al. Comparative study on bio-hydrogen production from corn stover: photo-fermentation, dark-fermentation and dark-photo co-fermentation[J]. International Journal of Hydrogen Energy, 2020, 45(6): 3807-3814. |

| 16 | THAUER R K, JUNGERMANN K, DECKER K. Energy conservation in chemotrophic anaerobic bacteria[J]. Bacteriological Reviews, 1977, 41(1): 100-180. |

| 17 | AKAÇIN İ, ERSOY Ş, KESKIN T, et al. Optimizing biohydrogen production yields by employing locally isolated thermophilic bacteria from hot springs[J]. International Journal of Hydrogen Energy, 2024, 52: 502-510. |

| 18 | XING D F, REN N Q, WANG A J, et al. Continuous hydrogen production of auto-aggregative Ethanoligenens harbinense YUAN-3 under non-sterile condition[J]. International Journal of Hydrogen Energy, 2008, 33(5): 1489-1495. |

| 19 | SINGH R, WHITE D, DEMIREL Y, et al. Uncoupling fermentative synthesis of molecular hydrogen from biomass formation in Thermotoga maritima [J]. Applied and Environmental Microbiology, 2018, 84(17): e00998-18. |

| 20 | YE X H, WANG Y R, HOPKINS R C, et al. Spontaneous high-yield production of hydrogen from cellulosic materials and water catalyzed by enzyme cocktails[J]. ChemSusChem, 2009, 2(2): 149-152. |

| 21 | ZHANG Y H, EVANS B R, MIELENZ J R, et al. High-yield hydrogen production from starch and water by a synthetic enzymatic pathway[J]. PLoS One, 2007, 2(5): e456. |

| 22 | ZHANG Y H P. Using extremophile enzymes to generate hydrogen for electricity[J]. Microbe Magazine, 2009, 4(12): 560-565. |

| 23 | Call for views: synthetic biology [OL]. The Royal Society, 2023,6: 2. . |

| 24 | CORREDOR J, HARANKAHAGE D, GLOAGUEN F, et al. Influence of QD photosensitizers in the photocatalytic production of hydrogen with biomimetic[FeFe]-hydrogenase. Comparative performance of CdSe and CdTe[J]. Chemosphere, 2021, 278: 130485. |

| 25 | ZHANG L Y, MORELLO G, CARR S B, et al. Aerobic photocatalytic H2 production by a [NiFe] hydrogenase engineered to place a silver nanocluster in the electron relay[J]. Journal of the American Chemical Society, 2020, 142(29): 12699-12707. |

| 26 | EDWARDES MOORE E, ANDREI V, ZACARIAS S, et al. Integration of a hydrogenase in a lead halide perovskite photoelectrode for tandem solar water splitting[J]. ACS Energy Letters, 2020, 5(1): 232-237. |

| 27 | SAKAI T, MERSCH D, REISNER E. Photocatalytic hydrogen evolution with a hydrogenase in a mediator-free system under high levels of oxygen[J]. Angewandte Chemie International Edition, 2013, 52(47): 12313-12316. |

| 28 | JI H S, WAN L, GAO Y X, et al. Hydrogenase as the basis for green hydrogen production and utilization[J]. Journal of Energy Chemistry, 2023, 85: 348-362. |

| 29 | KIM E J, KIM J E, ZHANG Y H P J. Ultra-rapid rates of water splitting for biohydrogen gas production through in vitro artificial enzymatic pathways[J]. Energy & Environmental Science, 2018, 11(8): 2064-2072. |

| 30 | LUBITZ W, OGATA H, RÜDIGER O, et al. Hydrogenases [J]. Chemical Reviews, 2014, 114(8): 4081-148. |

| 31 | STEPHENSON M, STICKLAND L H. Hydrogenase: a bacterial enzyme activating molecular hydrogen: the properties of the enzyme[J]. Biochemical Journal, 1931, 25(1): 205-214. |

| 32 | FRIEDRICH B, FRITSCH J, LENZ O. Oxygen-tolerant hydrogenases in hydrogen-based technologies[J]. Current Opinion in Biotechnology, 2011, 22(3): 358-364. |

| 33 | ARRIAZA-GALLARDO F J, ZHENG Y C, GEHL M, et al. [Fe]-hydrogenase, cofactor biosynthesis and engineering[J]. ChemBioChem, 2023, 24(20): e202300330. |

| 34 | PICHÉ-CHOQUETTE S, CONSTANT P. Molecular hydrogen, a neglected key driver of soil biogeochemical processes[J]. Applied and Environmental Microbiology, 2019, 85(6): e02418-18. |

| 35 | BEATON S E, EVANS R M, FINNEY A J, et al. The structure of hydrogenase-2 from Escherichia coli: implications for H2-driven proton pumping[J]. Biochemical Journal, 2018, 475(7): 1353-1370. |

| 36 | ROHAC R, MARTIN L, LIU L, et al. Crystal structure of the [FeFe]-hydrogenase maturase HydE bound to complex-B[J]. Journal of the American Chemical Society, 2021, 143(22): 8499-8508. |

| 37 | MAEDA T, SANCHEZ-TORRES V, WOOD T K. Hydrogen production by recombinant Escherichia coli strains[J]. Microbial Biotechnology, 2012, 5(2): 214-225. |

| 38 | ANWAR M, LOU S L, CHEN L, et al. Recent advancement and strategy on bio-hydrogen production from photosynthetic microalgae[J]. Bioresource Technology, 2019, 292: 121972. |

| 39 | VALLE A, CANTERO D, BOLÍVAR J. Metabolic engineering for the optimization of hydrogen production in Escherichia coli: a review[J]. Biotechnology Advances, 2019, 37(5): 616-633. |

| 40 | XUAN J S, HE L L, WEN W, et al. Hydrogenase and nitrogenase: key catalysts in biohydrogen production[J]. Molecules, 2023, 28(3): 1392. |

| 41 | WANG Y M, SONG Y H, MA C L, et al. A heterologously-expressed thermostable Pyrococcus furiosus cytoplasmic [NiFe]-hydrogenaseⅠused as the catalyst of H2/air biofuel cells[J]. International Journal of Hydrogen Energy, 2021, 46(4): 3035-3044. |

| 42 | JENNEY F E JR, ADAMS M W W. Hydrogenases of the model hyperthermophiles[J]. Annals of the New York Academy of Sciences, 2008, 1125: 252-266. |

| 43 | SUN J S, HOPKINS R C, JENNEY F E, et al. Heterologous expression and maturation of an NADP-dependent [NiFe]- hydrogenase: a key enzyme in biofuel production[J]. PLoS One, 2010, 5(5): e10526. |

| 44 | CHANDRAYAN S K, MCTERNAN P M, HOPKINS R C, et al. Engineering hyperthermophilic archaeon Pyrococcus furiosus to overproduce its cytoplasmic [NiFe]-hydrogenase[J]. Journal of Biological Chemistry, 2012, 287(5): 3257-3264. |

| 45 | SONG Y H, LIU M X, XIE L P, et al. A recombinant 12-His tagged Pyrococcus furiosus soluble [NiFe]-hydrogenaseⅠoverexpressed in Thermococcus kodakarensis KOD1 facilitates hydrogen-powered in vitro NADH regeneration[J]. Biotechnology Journal, 2019, 14(4): e1800301. |

| 46 | MEYER J. [FeFe] hydrogenases and their evolution: a genomic perspective[J]. Cellular and Molecular Life Sciences, 2007, 64(9): 1063-1084. |

| 47 | GREENING C, CABOTAJE P R, VALENTIN ALVARADO L E, et al. Minimal and hybrid hydrogenases are active from Archaea[J]. Cell, 2024, 187(13): 3357-3372.e19. |

| 48 | KIM E J, WU C H, ADAMS M W, et al. Exceptionally high rates of biological hydrogen production by biomimetic in vitro synthetic enzymatic pathways[J]. Chemistry, 2016, 22(45): 16047-16051. |

| 49 | KOO J, SHIIGI S, ROHOVIE M, et al. Characterization of [FeFe] hydrogenase O2 sensitivity using a new, physiological approach[J]. Journal of Biological Chemistry, 2016, 291(41): 21563-21570. |

| 50 | SHIMA S, THAUER R K. A third type of hydrogenase catalyzing H2 activation[J]. Chemical Record, 2007, 7(1): 37-46. |

| 51 | LEONE L, SGUEGLIA G, LA GATTA S, et al. Enzymatic and bioinspired systems for hydrogen production[J]. International Journal of Molecular Sciences, 2023, 24(10): 8605. |

| 52 | WEI W, SUN P Q, LI Z, et al. A surface-display biohybrid approach to light-driven hydrogen production in air[J]. Science Advances, 2018, 4(2): eaap9253. |

| 53 | SZCZESNY J, BIRRELL J A, CONZUELO F, et al. Redox-polymer-based high-current-density gas-diffusion H2-oxidation bioanode using [FeFe] hydrogenase from Desulfovibrio desulfuricans in a membrane-free biofuel cell[J]. Angewandte Chemie International Edition, 2020, 59(38): 16506-16510. |

| 54 | AL-SHAMERI A, SIEBERT D L, SUTIONO S, et al. Hydrogenase-based oxidative biocatalysis without oxygen[J]. Nature Communications, 2023, 14: 2693. |

| 55 | LI F, LUTZ P B, PEPELYAYEVA Y, et al. Redox active motifs in selenoproteins[J]. Proceedings of the National Academy of Sciences of the United States of America, 2014, 111(19): 6976-6981. |

| 56 | CHUNG C Z, KRAHN N. The selenocysteine toolbox: a guide to studying the 21st amino acid[J]. Archives of Biochemistry and Biophysics, 2022, 730: 109421. |

| 57 | HONDAL R J, MARINO S M, GLADYSHEV V N. Selenocysteine in thiol/disulfide-like exchange reactions[J]. Antioxidants & Redox Signaling, 2013, 18(13): 1675-1689. |

| 58 | MARQUES M C, TAPIA C, GUTIÉRREZ-SANZ O, et al. The direct role of selenocysteine in [NiFeSe] hydrogenase maturation and catalysis[J]. Nature Chemical Biology, 2017, 13(5): 544-550. |

| 59 | BROOKE E J, EVANS R M, ISLAM S T A, et al. Importance of the active site “canopy” residues in an O2-tolerant [NiFe]-hydrogenase[J]. Biochemistry, 2017, 56(1): 132-142. |

| 60 | MCGUIRE A D, GENET H, LYU Z, et al. Assessing historical and projected carbon balance of Alaska: a synthesis of results and policy/management implications[J]. Ecological Applications, 2018, 28(6): 1396-1412. |

| 61 | PATEL A, MULDER D W, SÖLL D, et al. Harnessing selenocysteine to enhance microbial cell factories for hydrogen production[J]. Frontiers in Catalysis, 2022, 2: 1089176. |

| 62 | ABOU HAMDAN A, BURLAT B, GUTIÉRREZ-SANZ O, et al. O2-independent formation of the inactive states of NiFe hydrogenase[J]. Nature Chemical Biology, 2013, 9(1): 15-17. |

| 63 | FRITSCH J, LENZ O, FRIEDRICH B. Structure, function and biosynthesis of O₂-tolerant hydrogenases[J]. Nature Reviews Microbiology, 2013, 11(2): 106-114. |

| 64 | PANDELIA M E, NITSCHKE W, INFOSSI P, et al. Characterization of a unique [FeS] cluster in the electron transfer chain of the oxygen tolerant [NiFe] hydrogenase from Aquifex aeolicus [J]. Proceedings of the National Academy of Sciences of the United States of America, 2011, 108(15): 6097-6102. |

| 65 | WULFF P, THOMAS C, SARGENT F, et al. How the oxygen tolerance of a [NiFe]-hydrogenase depends on quaternary structure[J]. Journal of Biological Inorganic Chemistry, 2016, 21(1): 121-134. |

| 66 | KUBAS A, ORAIN C, DE SANCHO D, et al. Mechanism of O2 diffusion and reduction in FeFe hydrogenases[J]. Nature Chemistry, 2017, 9(1): 88-95. |

| 67 | STRIPP S T, GOLDET G, BRANDMAYR C, et al. How oxygen attacks [FeFe] hydrogenases from photosynthetic organisms[J]. Proceedings of the National Academy of Sciences of the United States of America, 2009, 106(41): 17331-17336. |

| 68 | VINCENT K A, PARKIN A, LENZ O, et al. Electrochemical definitions of O2 sensitivity and oxidative inactivation in hydrogenases[J]. Journal of the American Chemical Society, 2005, 127(51): 18179-18189. |

| 69 | ORAIN C, SAUJET L, GAUQUELIN C, et al. Electrochemical measurements of the kinetics of inhibition of two FeFe hydrogenases by O2 demonstrate that the reaction is partly reversible[J]. Journal of the American Chemical Society, 2015, 137(39): 12580-12587. |

| 70 | BINGHAM A S, SMITH P R, SWARTZ J R. Evolution of an [FeFe] hydrogenase with decreased oxygen sensitivity[J]. International Journal of Hydrogen Energy, 2012, 37(3): 2965-2976. |

| 71 | FONTECILLA-CAMPS J C, VOLBEDA A, CAVAZZA C, et al. Structure/function relationships of [NiFe]- and [FeFe]-hydrogenases[J]. Chemical Reviews, 2007, 107(10): 4273-4303. |

| 72 | PAPINI C, SOMMER C, PECQUEUR L, et al. Bioinspired artificial [FeFe]-hydrogenase with a synthetic H-cluster[J]. ACS Catalysis, 2019, 9(5): 4495-4501. |

| 73 | LIEBGOTT P P, LEROUX F, BURLAT B, et al. Relating diffusion along the substrate tunnel and oxygen sensitivity in hydrogenase[J]. Nature Chemical Biology, 2010, 6(1): 63-70. |

| 74 | BAFFERT C, DEMUEZ M, COURNAC L, et al. Hydrogen-activating enzymes: activity does not correlate with oxygen sensitivity[J]. Angewandte Chemie International Edition, 2008, 47(11): 2052-2054. |

| 75 | LAMPRET O, DUAN J F, HOFMANN E, et al. The roles of long-range proton-coupled electron transfer in the directionality and efficiency of [FeFe]-hydrogenases[J]. Proceedings of the National Academy of Sciences of the United States of America, 2020, 117(34): 20520-20529. |

| 76 | RUTZ A, DAS C K, FASANO A, et al. Increasing the O2 resistance of the [FeFe]-hydrogenase CbA5H through enhanced protein flexibility[J]. ACS Catalysis, 2023, 13(2): 856-865. |

| 77 | LU Y, KOO J. O2 sensitivity and H2 production activity of hydrogenases - a review[J]. Biotechnology and Bioengineering, 2019, 116(11): 3124-3135. |

| 78 | CRACKNELL J A, WAIT A F, LENZ O, et al. A kinetic and thermodynamic understanding of O2 tolerance in [NiFe]- hydrogenases[J]. Proceedings of the National Academy of Sciences of the United States of America, 2009, 106(49): 20681-20686. |

| 79 | GORIS T, WAIT A F, SAGGU M, et al. A unique iron-sulfur cluster is crucial for oxygen tolerance of a [NiFe]-hydrogenase[J]. Nature Chemical Biology, 2011, 7(5): 310-318. |

| 80 | WULFF P, DAY C C, SARGENT F, et al. How oxygen reacts with oxygen-tolerant respiratory [NiFe]-hydrogenases[J]. Proceedings of the National Academy of Sciences of the United States of America, 2014, 111(18): 6606-6611. |

| 81 | FRIELINGSDORF S, FRITSCH J, SCHMIDT A, et al. Reversible [4Fe-3S]cluster morphing in an O2-tolerant [NiFe] hydrogenase[J]. Nature Chemical Biology, 2014, 10(5): 378-385. |

| 82 | FRITSCH J, SCHEERER P, FRIELINGSDORF S, et al. The crystal structure of an oxygen-tolerant hydrogenase uncovers a novel iron-sulphur centre[J]. Nature, 2011, 479(7372): 249-252. |

| 83 | SIEGBAHN P E M, TYE J W, HALL M B. Computational studies of [NiFe] and [FeFe] hydrogenases[J]. Chemical Reviews, 2007, 107(10): 4414-4435. |

| 84 | SÖDERHJELM P, RYDE U. Combined computational and crystallographic study of the oxidised states of [NiFe] hydrogenase[J]. Journal of Molecular Structure: THEOCHEM, 2006, 770(1/2/3): 199-219. |

| 85 | STEIN M, LUBITZ W. Quantum chemical calculations of [NiFe] hydrogenase[J]. Current Opinion in Chemical Biology, 2002, 6(2): 243-249. |

| 86 | FLANAGAN L A, CHIDWICK H S, WALTON J, et al. Conserved histidine adjacent to the proximal cluster tunes the anaerobic reductive activation of Escherichia coli membrane-bound [NiFe] hydrogenase-1[J]. ChemElectroChem, 2018, 5(6): 855-860. |

| 87 | VOLBEDA A, MOUESCA J M, DARNAULT C, et al. X-ray structural, functional and computational studies of the O2-sensitive E. coli hydrogenase-1 C19G variant reveal an unusual [4Fe-4S] cluster[J]. Chemical Communications, 2018, 54(52): 7175-7178. |

| 88 | RODRÍGUEZ-MACIÁ P, REIJERSE E J, VAN GASTEL M, et al. Sulfide protects [FeFe] hydrogenases from O2 [J]. Journal of the American Chemical Society, 2018, 140(30): 9346-9350. |

| 89 | XIONG W, ZHAO X H, ZHU G X, et al. Silicification-induced cell aggregation for the sustainable production of H2 under aerobic conditions[J]. Angewandte Chemie International Edition, 2015, 54(41): 11961-11965. |

| 90 | PLUMERÉ N, RÜDIGER O, OUGHLI A A, et al. A redox hydrogel protects hydrogenase from high-potential deactivation and oxygen damage[J]. Nature Chemistry, 2014, 6(9): 822-827. |

| 91 | EILENBERG H, WEINER I, BEN-ZVI O, et al. The dual effect of a ferredoxin-hydrogenase fusion protein in vivo: successful divergence of the photosynthetic electron flux towards hydrogen production and elevated oxygen tolerance[J]. Biotechnology for Biofuels, 2016, 9(1): 182. |

| 92 | LI T P, JIANG Q Y, HUANG J F, et al. Reprogramming bacterial protein organelles as a nanoreactor for hydrogen production[J]. Nature Communications, 2020, 11(1): 5448. |

| 93 | GHIRARDI M L. Implementation of photobiological H2 production: the O2 sensitivity of hydrogenases[J]. Photosynthesis Research, 2015, 125(3): 383-393. |

| 94 | WECKER M S A, GHIRARDI M L. High-throughput biosensor discriminates between different algal H2-photoproducing strains[J]. Biotechnology and Bioengineering, 2014, 111(7): 1332-1340. |

| 95 | KOO J, SCHNABEL T, LIONG S, et al. High-throughput screening of catalytic H2 production[J]. Angewandte Chemie International Edition, 2017, 56(4): 1012-1016. |

| 96 | ATTA M, MEYER J. Characterization of the gene encoding the [Fe]-hydrogenase from Megasphaera elsdenii [J]. Biochimica et Biophysica Acta, 2000, 1476(2): 368-371. |

| 97 | VOORDOUW G, HAGEN W R, KRÜSE-WOLTERS K M, et al. Purification and characterization of Desulfovibrio vulgaris (Hildenborough) hydrogenase expressed in Escherichia coli [J]. European Journal of Biochemistry, 1987, 162(1): 31-36. |

| 98 | ASADA Y, KOIKE Y, SCHNACKENBERG J, et al. Heterologous expression of clostridial hydrogenase in the Cyanobacterium synechococcus PCC7942[J]. Biochimica et Biophysica Acta, 2000, 1490(3): 269-278. |

| 99 | GORWA M F, CROUX C, SOUCAILLE P. Molecular characterization and transcriptional analysis of the putative hydrogenase gene of Clostridium acetobutylicum ATCC 824[J]. Journal of Bacteriology, 1996, 178(9): 2668-2675. |

| 100 | DEMUEZ M, COURNAC L, GUERRINI O, et al. Complete activity profile of Clostridium acetobutylicum [FeFe]-hydrogenase and kinetic parameters for endogenous redox partners[J]. FEMS Microbiology Letters, 2007, 275(1): 113-121. |

| 101 | KING P W, POSEWITZ M C, GHIRARDI M L, et al. Functional studies of [FeFe] hydrogenase maturation in an Escherichia coli biosynthetic system[J]. Journal of Bacteriology, 2006, 188(6): 2163-2172. |

| 102 | AKHTAR M K, JONES P R. Deletion of iscR stimulates recombinant clostridial Fe-Fe hydrogenase activity and H2-accumulation in Escherichia coli BL21(DE3)[J]. Applied Microbiology and Biotechnology, 2008, 78(5): 853-862. |

| 103 | DUCAT D C, SACHDEVA G, SILVER P A. Rewiring hydrogenase-dependent redox circuits in cyanobacteria[J]. Proceedings of the National Academy of Sciences of the United States of America, 2011, 108(10): 3941-3946. |

| 104 | SUBUDHI S, LAL B. Fermentative hydrogen production in recombinant Escherichia coli harboring a [FeFe]-hydrogenase gene isolated from Clostridium butyricum [J]. International Journal of Hydrogen Energy, 2011, 36(21): 14024-14030. |

| 105 | ADAMS M W W, MORTENSON L E. The purification of hydrogenase Ⅱ (uptake hydrogenase) from the anaerobic N2-fixing bacterium Clostridium pasteurianum [J]. Biochimica et Biophysica Acta (BBA) - Bioenergetics, 1984, 766(1): 51-61. |

| 106 | KUCHENREUTHER J M, GRADY-SMITH C S, BINGHAM A S, et al. High-yield expression of heterologous [FeFe] hydrogenases in Escherichia coli [J]. PLoS One, 2010, 5(11): e15491. |

| 107 | KAMP C, SILAKOV A, WINKLER M, et al. Isolation and first EPR characterization of the [FeFe]-hydrogenases from green algae[J]. Biochimica et Biophysica Acta, 2008, 1777(5): 410-416. |

| 108 | GIRBAL L, VON ABENDROTH G, WINKLER M, et al. Homologous and heterologous overexpression in Clostridium acetobutylicum and characterization of purified clostridial and algal Fe-only hydrogenases with high specific activities[J]. Applied and Environmental Microbiology, 2005, 71(5): 2777-2781. |

| 109 | VON ABENDROTH G, STRIPP S, SILAKOV A, et al. Optimized over-expression of [FeFe] hydrogenases with high specific activity in Clostridium acetobutylicum [J]. International Journal of Hydrogen Energy, 2008, 33(21): 6076-6081. |

| 110 | POSEWITZ M C, KING P W, SMOLINSKI S L, et al. Discovery of two novel radical S-adenosylmethionine proteins required for the assembly of an active [Fe] hydrogenase[J]. Journal of Biological Chemistry, 2004, 279(24): 25711-25720. |

| 111 | YACOBY I, TEGLER L T, POCHEKAILOV S, et al. Optimized expression and purification for high-activity preparations of algal [FeFe]-hydrogenase[J]. PLoS One, 2012, 7(4): e35886. |

| 112 | SYBIRNA K, ANTOINE T, LINDBERG P, et al. Shewanella oneidensis: a new and efficient system for expression and maturation of heterologous [Fe-Fe] hydrogenase from Chlamydomonas reinhardtii [J]. BMC Biotechnology, 2008, 8: 73. |

| 113 | BERTO P, D’ADAMO S, BERGANTINO E, et al. The Cyanobacterium synechocystis sp. PCC 6803 is able to express an active [FeFe]-hydrogenase without additional maturation proteins[J]. Biochemical and Biophysical Research Communications, 2011, 405(4): 678-683. |

| 114 | KELLY C L, PINSKE C, MURPHY B J, et al. Integration of an [FeFe]-hydrogenase into the anaerobic metabolism of Escherichia coli [J]. Biotechnology Reports, 2015, 8: 94-104. |

| 115 | ZHAO X, XING D F, ZHANG L, et al. Characterization and overexpression of a [FeFe]-hydrogenase gene of a novel hydrogen-producing bacterium Ethanoligenens harbinense [J]. International Journal of Hydrogen Energy, 2010, 35(18): 9598-9602. |

| 116 | NIXON J E, FIELD J, MCARTHUR A G, et al. Iron-dependent hydrogenases of Entamoeba histolytica and Giardia lamblia: activity of the recombinant entamoebic enzyme and evidence for lateral gene transfer[J]. The Biological Bulletin, 2003, 204(1): 1-9. |

| 117 | INOUE J I, SAITA K, KUDO T, et al. Hydrogen production by termite gut protists: characterization of iron hydrogenases of parabasalian symbionts of the termite Coptotermes formosanus [J]. Eukaryotic Cell, 2007, 6(10): 1925-1932. |

| 118 | GÄRTNER K, LECHNO-YOSSEF S, CORNISH A J, et al. Expression of Shewanella oneidensis MR-1[FeFe]- hydrogenase genes in Anabaena sp. strain PCC 7120[J]. Applied and Environmental Microbiology, 2012, 78(24): 8579-8586. |

| 119 | VARGAS W A, WEYMAN P D, TONG Y K, et al. [NiFe] hydrogenase from Alteromonas macleodii with unusual stability in the presence of oxygen and high temperature[J]. Applied and Environmental Microbiology, 2011, 77(6): 1990-1998. |

| 120 | WEYMAN P D, VARGAS W A, CHUANG R Y, et al. Heterologous expression of Alteromonas macleodii and Thiocapsa roseopersicina [NiFe] hydrogenases in Escherichia coli [J]. Microbiology, 2011, 157(Pt 5): 1363-1374. |

| 121 | YONEMOTO I T, MATTERI C W, NGUYEN T A, et al. Dual organism design cycle reveals small subunit substitutions that improve [NiFe] hydrogenase hydrogen evolution[J]. Journal of Biological Engineering, 2013, 7(1): 17. |

| 122 | MARÓTI G, TONG Y K, YOOSEPH S, et al. Discovery of [NiFe] hydrogenase genes in metagenomic DNA cloning and heterologous expression in Thiocapsa roseopersicina [J]. Applied and Environmental Microbiology, 2009, 75(18): 5821-5830. |

| 123 | MURA G M, PEDRONI P, PRATESI C, et al. The [Ni-Fe] hydrogenase from the thermophilic bacterium Acetomicrobium flavidum [J]. Microbiology, 1996, 142( Pt 4): 829-836. |

| 124 | HATCHIKIAN E C, BRUSCHI M, LE GALL J. Characterization of the periplasmic hydrogenase from Desulfovibrio gigas [J]. Biochemical and Biophysical Research Communications, 1978, 82(2): 451-461. |

| 125 | ROUSSET M, MAGRO V, FORGET N, et al. Heterologous expression of the Desulfovibrio gigas [NiFe] hydrogenase in Desulfovibrio fructosovorans MR400[J]. Journal of Bacteriology, 1998, 180(18): 4982-4986. |

| 126 | KIM J Y H, JO B H, CHA H J. Production of biohydrogen by recombinant expression of [NiFe]-hydrogenase 1 in Escherichia coli [J]. Microbial Cell Factories, 2010, 9: 54. |

| 127 | KIM J Y H, JO B H, CHA H J. Production of biohydrogen by heterologous expression of oxygen-tolerant Hydrogenovibrio marinus [NiFe]-hydrogenase in Escherichia coli [J]. Journal of Biotechnology, 2011, 155(3): 312-319. |

| 128 | RALEIRAS P, KHANNA N, MIRANDA H, et al. Turning around the electron flow in an uptake hydrogenase. EPR spectroscopy and in vivo activity of a designed mutant in HupSL from Nostoc punctiforme [J]. Energy & Environmental Science, 2016, 9(2): 581-594. |

| 129 | SCHINK B, SCHLEGEL H G. The membrane-bound hydrogenase of Alcaligenes eutrophus.Ⅰ. Solubilization, purification, and biochemical properties[J]. Biochimica et Biophysica Acta, 1979, 567(2): 315-324. |

| 130 | LENZ O, GLEICHE A, STRACK A, et al. Requirements for heterologous production of a complex metalloenzyme: the membrane-bound [NiFe] hydrogenase[J]. Journal of Bacteriology, 2005, 187(18): 6590-6595. |

| 131 | BUHRKE T, LENZ O, KRAUSS N, et al. Oxygen tolerance of the H2-sensing [NiFe] hydrogenase from Ralstonia eutropha H16 is based on limited access of oxygen to the active site[J]. Journal of Biological Chemistry, 2005, 280(25): 23791-23796. |

| 132 | SCHIFFELS J, PINKENBURG O, SCHELDEN M, et al. An innovative cloning platform enables large-scale production and maturation of an oxygen-tolerant [NiFe]-hydrogenase from Cupriavidus necator in Escherichia coli [J]. PLoS One, 2013, 8(7): e68812. |

| 133 | PORTHUN A, BERNHARD M, FRIEDRICH B. Expression of a functional NAD-reducing [NiFe] hydrogenase from the gram-positive Rhodococcus opacus in the Gram-negative Ralstonia eutropha [J]. Archives of Microbiology, 2002, 177(2): 159-166. |

| 134 | WELLS M A, MERCER J, MOTT R A, et al. Engineering a non-native hydrogen production pathway into Escherichia coli via a cyanobacterial [NiFe] hydrogenase[J]. Metabolic Engineering, 2011, 13(4): 445-453. |

| 135 | PREISSLER J, WAHLEFELD S, LORENT C, et al. Enzymatic and spectroscopic properties of a thermostable [NiFe]- hydrogenase performing H2-driven NAD+-reduction in the presence of O2 [J]. Biochimica et Biophysica Acta Bioenergetics, 2018, 1859(1): 8-18. |

| 136 | RIECKENBERG F, GÖTZ K, HILTERHAUS L, et al. Strategies for reliable and improved large-scale production of Pyrococcus furiosus with integrated purification of hydrogenaseⅠ[J]. Bioprocess and Biosystems Engineering, 2014, 37(12): 2475-2482. |

| 137 | SOBOH B, LINDENSTRAUSS U, GRANICH C, et al. [NiFe]-hydrogenase maturation in vitro: analysis of the roles of the HybG and HypD accessory proteins 1[J]. Biochemical Journal, 2014, 464(2): 169-177. |

| 138 | PAGNIER A, BALCI B, SHEPARD E M, et al. [FeFe]- hydrogenase in vitro maturation[J]. Angewandte Chemie International Edition, 2022, 61(49): e202212074. |

| 139 | KÖHLER V, WILSON Y M, DÜRRENBERGER M, et al. Synthetic cascades are enabled by combining biocatalysts with artificial metalloenzymes[J]. Nature Chemistry, 2013, 5(2): 93-99. |

| 140 | MAITY B, TAHER M, MAZUMDAR S, et al. Artificial metalloenzymes based on protein assembly[J]. Coordination Chemistry Reviews, 2022, 469: 214593. |

| 141 | ONODA A, HAYASHI T. Artificial hydrogenase: biomimetic approaches controlling active molecular catalysts[J]. Current Opinion in Chemical Biology, 2015, 25: 133-140. |

| 142 | VOLBEDA A, CHARON M H, PIRAS C, et al. Crystal structure of the nickel-iron hydrogenase from Desulfovibrio gigas [J]. Nature, 1995, 373(6515): 580-587. |

| 143 | DARAOSHEH A Q, ABUL-FUTOUH H, MURAKAMI N, et al. Novel [FeFe]-hydrogenase mimics: unexpected course of the reaction of ferrocenyl α-thienyl thioketone with Fe3(CO)12 [J]. Materials, 2022, 15(8): 2867. |

| 144 | LAND H, SENGER M, BERGGREN G, et al. Current state of [FeFe]-hydrogenase research: biodiversity and spectroscopic investigations[J]. ACS Catalysis, 2020, 10(13): 7069-7086. |

| 145 | 石婷, 宋展, 宋世怡, 等. 体外生物转化(ivBT):生物制造的新前沿 [J]. 合成生物学, 2024, 5(6):1437-1460. |

| SHI T, SONG Z, SONG S Y, et al. In vitro BioTransformation (ivBT): a new frontier of industrial biomanufacturing [J]. Synthetic Biology Journal, 2024, 5(6):1437-1460. | |

| 146 | KIM J E, KIM E J, CHEN H, et al. Advanced water splitting for green hydrogen gas production through complete oxidation of starch by in vitro metabolic engineering[J]. Metabolic Engineering, 2017, 44: 246-252. |

| 147 | BOMMARIUS A S, PAYE M F. Stabilizing biocatalysts[J]. Chemical Society Reviews, 2013, 42(15): 6534-6565. |

| 148 | ZHANG Y H P. Production of biocommodities and bioelectricity by cell-free synthetic enzymatic pathway biotransformations: challenges and opportunities[J]. Biotechnology and Bioengineering, 2010, 105(4): 663-677. |

| 149 | ROLLIN J A, MARTIN DEL CAMPO J, MYUNG S, et al. High-yield hydrogen production from biomass by in vitro metabolic engineering: mixed sugars coutilization and kinetic modeling[J]. Proceedings of the National Academy of Sciences of the United States of America, 2015, 112(16): 4964-4969. |

| 150 | 雷航彬, 何宁, 李斐煊,等. 氢化酶固定化研究进展 [J]. 合成生物学, 2024, 5(6):1485-1497. |

| LEI H B, HE N, LI F X, et al. Advance in the immobilization of hydrogenases [J]. Synthetic Biology Journal, 2024, 5(6):1485-1497. | |

| 151 | ROSANO G L, MORALES E S, CECCARELLI E A. New tools for recombinant protein production in Escherichia coli: a 5-year update[J]. Protein Science, 2019, 28(8): 1412-1422. |

| 152 | ZHOU Y L, LU Z H, WANG X, et al. Genetic engineering modification and fermentation optimization for extracellular production of recombinant proteins using Escherichia coli [J]. Applied Microbiology and Biotechnology, 2018, 102(4): 1545-1556. |

| 153 | LIU J H, LI H L, ZHAO G R, et al. Redox cofactor engineering in industrial microorganisms: strategies, recent applications and future directions[J]. Journal of Industrial Microbiology & Biotechnology, 2018, 45(5): 313-327. |

| 154 | COVARRUBIAS A J, PERRONE R, GROZIO A, et al. NAD+ metabolism and its roles in cellular processes during ageing[J]. Nature Reviews Molecular Cell Biology, 2021, 22(2): 119-141. |

| 155 | ESTRELLA M A, DU J, CHEN L, et al. The metabolites NADP+ and NADPH are the targets of the circadian protein Nocturnin (Curled)[J]. Nature Communications, 2019, 10(1): 2367. |

| 156 | HOLM A K, BLANK L M, OLDIGES M, et al. Metabolic and transcriptional response to cofactor perturbations in Escherichia coli [J]. Journal of Biological Chemistry, 2010, 285(23): 17498-17506. |

| 157 | ANDERSON B M, KAPLAN N O. Enzymatic studies with analogues of diphosphopyridine nucleotide[J]. Journal of Biological Chemistry, 1959, 234(5): 1226-1232. |

| 158 | LIU Y X, LI Q, WANG L, et al. Engineering D-lactate dehydrogenase to favor an non-natural cofactor nicotinamide cytosine dinucleotide[J]. ChemBioChem, 2020, 21(14): 1972-1975. |

| 159 | GUO X J, LIU Y X, WANG Q, et al. Non-natural cofactor and formate-driven reductive carboxylation of pyruvate[J]. Angewandte Chemie International Edition, 2020, 59(8): 3143-3146. |

| 160 | NOWAK C, PICK A, LOMMES P, et al. Enzymatic reduction of nicotinamide biomimetic cofactors using an engineered glucose dehydrogenase: providing a regeneration system for artificial cofactors[J]. ACS Catalysis, 2017, 7(8): 5202-5208. |

| 161 | YOU C, HUANG R, WEI X L, et al. Protein engineering of oxidoreductases utilizing nicotinamide-based coenzymes, with applications in synthetic biology[J]. Synthetic and Systems Biotechnology, 2017, 2(3): 208-218. |

| 162 | BLACK W B, ZHANG L Y, MAK W S, et al. Engineering a nicotinamide mononucleotide redox cofactor system for biocatalysis[J]. Nature Chemical Biology, 2020, 16(1): 87-94. |

| 163 | HUANG R, CHEN H, UPP D M, et al. A high-throughput method for directed evolution of NAD(P)+-dependent dehydrogenases for the reduction of biomimetic nicotinamide analogues[J]. ACS Catalysis, 2019, 9(12): 11709-11719. |

| 164 | ZACHOS I, NOWAK C, SIEBER V. Biomimetic cofactors and methods for their recycling[J]. Current Opinion in Chemical Biology, 2019, 49: 59-66. |

| 165 | JI D B, WANG L, HOU S H, et al. Creation of bioorthogonal redox systems depending on nicotinamide flucytosine dinucleotide[J]. Journal of the American Chemical Society, 2011, 133(51): 20857-20862. |

| 166 | SHOJI S, YAMAJI T, MAKINO H, et al. Metabolic design for selective production of nicotinamide mononucleotide from glucose and nicotinamide[J]. Metabolic Engineering, 2021, 65: 167-177. |

| 167 | ZHANG P, YULY J L, LUBNER C E, et al. Electron bifurcation: thermodynamics and kinetics of two-electron brokering in biological redox chemistry[J]. Accounts of Chemical Research, 2017, 50(9): 2410-2417. |

| 168 | KANAI T, ITO S, IMANAKA T. Characterization of a cytosolic NiFe-hydrogenase from the hyperthermophilic archaeon Thermococcus kodakaraensis KOD1[J]. Journal of Bacteriology, 2003, 185(5): 1705-1711. |

| [1] | LEI Hangbin, HE Ning, LI Feixuan, DONG Lingling, WANG Shizhen. Advance in the immobilization of hydrogenases [J]. Synthetic Biology Journal, 2024, 5(6): 1485-1497. |

| [2] | LIU Xiangshi, WU Yilu, ZHAN Peng, HUANG Tianhao, CAI Di, QIN Peiyong. State-of-the-art for alcohol dehydrogenase development and the prospect of its applications in bio-based furan compounds valorization [J]. Synthetic Biology Journal, 2023, 4(6): 1122-1139. |

| [3] | LIU Weisong, ZHANG Kuncheng, CUI Huijuan, ZHU Zhiguang, ZHANG Yiheng, ZHANG Lingling. Electro-assisted carbon dioxide biotransformation [J]. Synthetic Biology Journal, 2023, 4(6): 1191-1222. |

| [4] | WANG Junting, GUO Xiaojia, LI Qing, WAN Li, ZHAO Zongbao. Creation of non-natural cofactor-dependent methanol dehydrogenase [J]. Synthetic Biology Journal, 2021, 2(4): 651-661. |

| [5] | LIU Meixia, LI Qiangzi, MENG Dongdong, WEI Xinlei, YOU Chun. Protein engineering of nicotinamide coenzyme-dependent oxidoreductases for coenzyme preference and its application in synthetic biology [J]. Synthetic Biology Journal, 2020, 1(5): 570-582. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||