|

|||||||||||||||||||||||||||||||||||||||

|

Applications of protein engineering in pharmaceutical industry

Synthetic Biology Journal

2025, 6 (1):

65-86.

DOI: 10.12211/2096-8280.2024-061

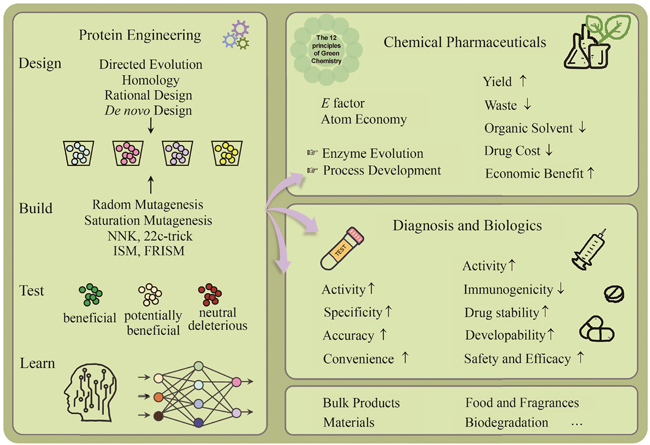

Protein engineering performs specific designs and modifications on proteins through directed evolution, semi-rational or rational design, computer-assisted design, and so on. The engineered proteins, with improved properties, have significant applications in food, medicine, fuel, and material industries. For the chemical and pharmaceutical industry, engineered enzymes can serve as efficient biocatalysts for the synthesis of active pharmaceutical ingredients (API) and their intermediates, aligning with the concepts and principles of green chemistry and manufacturing. For the biopharmaceutical industry, the engineering of peptide or protein modifying enzymes can boost the efficiency in preparing drug candidates, while engineered diagnostic enzymes can make detection more accurate and sensitive. Moreover, protein engineering can improve the bioactivities of biological drugs such as therapeutic enzymes and antibodies, increase stability, and mitigate immunogenic response for their safety and efficacy. Here, we review the tremendous progress in protein engineering, elucidate its importance in the research and development of chemically derived drugs and biologics, and provide examples of its applications. These examples encompass the discovery of enzymes or antibodies, the process of protein engineering, and the subsequent economic advantages. We aim to showcase the practical implementation of protein engineering in the pharmaceutical industry and facilitate technology transfer, thereby fostering seamless integration between research, development, and industrial production. Furthermore, we discuss challenges such as cost-effectiveness and market changes in the synthesis of API, and multi-target optimization, long cycle and high risk in the discovery and development of biopharmaceuticals. Finally, we look forward to the prospects of protein engineering in pharmaceutical industry. In the future, automated pipelines consisting artificial intelligence and self-driving laboratories will accelerate the design-build-test-learn cycle, leading to rapid progress in molecular design and discovery.

Table 1

Applications of protein engineering in the synthesis of active pharmaceutical ingredients

Extracts from the Article

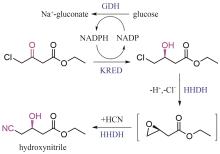

综上,在E因子和原子经济性概念以及绿色化学12项原则的指导下,生物催化的价值已被制药公司广泛认可,工程化酶在化学原料药及高附加值产品合成中取得的各项成果振奋人心[101]。在酶改造的同时关注工艺优化,可以获得与生产工艺相匹配的优良生物催化剂,增加化学原料及其中间体的产量,减少废弃物,减少有机溶剂使用,降低了药物生产成本,既减轻了患者的用药负担,又提高了制药企业的经济效益(表1)。除了前文提到的CodeEvolver?平台之外,近年来国内企业建立的BioEngine?和ZymeEditorTM等蛋白质改造平台在行业内占有举足轻重的地位。这些平台将高通量筛选、理性设计与人工智能有机结合,实现了高效和系统的蛋白质工程,为小分子药物绿色生物制造的快速发展提供了保障。

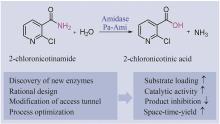

活性↑,稳定性↑,收率↑ ... Structure-guided semi-rational design of an imine reductase for enantio-complementary synthesis of pyrrolidinamine 1 2023 ... 亚胺还原酶(imine reductase,IRED)是一类NAD(P)H依赖的氧化还原酶,可催化前手性亚胺的不对称还原合成手性胺[ Biocatalytic reductive aminations with NAD(P)H-dependent enzymes: enzyme discovery, engineering and synthetic applications 1 2024 ... 亚胺还原酶(imine reductase,IRED)是一类NAD(P)H依赖的氧化还原酶,可催化前手性亚胺的不对称还原合成手性胺[ 亚胺还原酶在手性胺合成中的应用 1 2022 ... 亚胺还原酶(imine reductase,IRED)是一类NAD(P)H依赖的氧化还原酶,可催化前手性亚胺的不对称还原合成手性胺[ Application of imine reductase in the synthesis of chiral amines 1 2022 ... 亚胺还原酶(imine reductase,IRED)是一类NAD(P)H依赖的氧化还原酶,可催化前手性亚胺的不对称还原合成手性胺[ 甾体化合物绿色生物制造: 从生物转化到微生物从头合成 1 2021 ... 魏东芝团队[ Green biomanufacturing of steroids: from biotransformation to de novo synthesis by microorganisms 1 2021 ... 魏东芝团队[ 多酶催化体系在医药化学品合成中的应用 1 2021 ... 随着越来越多的生物催化剂被整合进化学转化过程,多酶级联反应[ Application of multi-enzyme catalytic system in the synthesis of pharmaceutical chemicals 1 2021 ... 随着越来越多的生物催化剂被整合进化学转化过程,多酶级联反应[ Green chemistry challenge: 2022 greener synthetic pathways award 1 ... 随着越来越多的生物催化剂被整合进化学转化过程,多酶级联反应[ Enzyme-mediated synthesis of molnupiravir: paving the way for the application of biocatalysis in pharmaceutical industry 0 2022 Streamlined chemo-enzymatic synthesis of molnupiravir via lipase catalyst 1 2024 ... 随着越来越多的生物催化剂被整合进化学转化过程,多酶级联反应[ Engineered enzymes for the synthesis of pharmaceuticals and other high-value products 1 2024 ... 综上,在E因子和原子经济性概念以及绿色化学12项原则的指导下,生物催化的价值已被制药公司广泛认可,工程化酶在化学原料药及高附加值产品合成中取得的各项成果振奋人心[ Therapeutic peptides: current applications and future directions 1 2022 ... 近年来,生物药(biopharmaceuticals)如重组蛋白和多肽[ Peptide-based drug discovery: current status and recent advances 0 2023 Peptides as therapeutic agents: challenges and opportunities in the green transition era 1 2023 ... 近年来,生物药(biopharmaceuticals)如重组蛋白和多肽[ FDA approves 100th monoclonal antibody product 2 2021 ... 近年来,生物药(biopharmaceuticals)如重组蛋白和多肽[

Other Images/Table from this Article

|