Advances in electro-microbial synergistic systems for value-added conversion of carbon dioxide

HAN Lin1, GUO Yuman2, LI Yan2, CAO Hengheng2, LI Jiajing2, YANG Minghao2, WANG Mengmeng2, LI Jinping1, LV Yongqin1,2

- 1.State Key Laboratory of Organic-Inorganic Composites,Beijing Advanced Innovation Center for Soft Matter Science and Engineering,Beijing University of Chemical Technology,Beijing,100029,China

2.National Energy R&D Center for Biorefinery,Beijing Key Laboratory of Green Chemicals Biomanufacturing,Beijing Synthetic Bio-manufacturing Technology Innovation Center,College of Life Science and Technology,Beijing University of Chemical Technology,Beijing 100029,China

-

Received:2025-07-01Revised:2025-10-01Published:2025-10-10 -

Contact:HAN Lin, LV Yongqin

电-微生物协同系统用于CO2高值转化的研究进展

韩林1, 郭禹曼2, 李燕2, 曹珩珩2, 李嘉婧2, 杨明浩2, 汪萌萌2, 李晋萍1, 吕永琴1,2

- 1.有机无机复合材料全国重点实验室,北京软物质科学与工程高精尖创新中心,北京化工大学,北京 100029

2.国家能源生物炼制研发中心,教育部生物能源国际合作联合实验室,绿色化学品生物制造北京市重点实验室,生命科学与技术学院,北京化工大学,北京 100029

-

通讯作者:韩林,吕永琴 -

作者简介:韩林 (1995—),男,博士研究生。研究方向为异位耦合电生物固碳。E-mail:mzkd1314@qq.com郭禹曼 (1999—),女,博士研究生。研究方向为光/电驱动生物固碳。E-mail:2023400321@buct.edu.cn吕永琴 (1983—),女,博士,教授,博士生导师。研究方向为光电驱动生物固碳,酶的分子改造和固定化,仿生抗体工程。国家重点研发计划首席科学家,国家优秀青年基金获得者。相关研究成果在PNAS、J. Am. Chem. Soc.、Matter、Adv. Energy Mater.、Adv. Sci.、Prog. Energ. Combust.等期刊发表SCI论文80余篇,申请发明专利三十余项。获侯德榜化工科学技术奖青年奖、教育部自然科学奖二等奖、石油化工联合会技术发明奖一等奖等奖项。先后主持了国家重点研发计划项目/课题、国家自然科学基金优秀青年基金项目、联合基金重点项目、国际合作项目等10余项。担任中国生物工程学会一碳生物技术专委会委员、中国化工学会青年工作委员会委员、中国生物工程学会生物催化专业委员会委员、中国化工学会女科技工作者委员会委员、中国微生物学会微生物代谢与生物制造专业委员会委员。担任5本SCI期刊的客座编辑和编委。E-mail:lvyq@mail.buct.edu.cn -

基金资助:国家重点研发计划(2024YFB4206300);国家自然科学基金(U22A20426);国家自然科学基金(22408017);国家自然科学基金(22122801);北京市自然科学基金(2244075)

CLC Number:

Cite this article

HAN Lin, GUO Yuman, LI Yan, CAO Hengheng, LI Jiajing, YANG Minghao, WANG Mengmeng, LI Jinping, LV Yongqin. Advances in electro-microbial synergistic systems for value-added conversion of carbon dioxide[J]. Synthetic Biology Journal, DOI: 10.12211/2096-8280.2025-070.

韩林, 郭禹曼, 李燕, 曹珩珩, 李嘉婧, 杨明浩, 汪萌萌, 李晋萍, 吕永琴. 电-微生物协同系统用于CO2高值转化的研究进展[J]. 合成生物学, DOI: 10.12211/2096-8280.2025-070.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: https://synbioj.cip.com.cn/EN/10.12211/2096-8280.2025-070

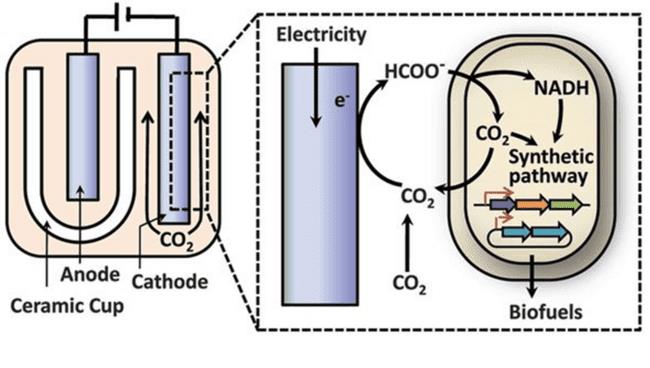

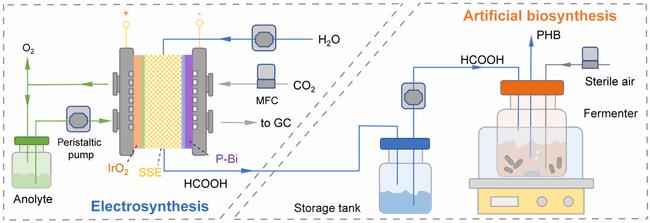

Fig. 8 Construction of an artificial photosynthesis system by integrating a photoelectrochemical system with genetically engineered cells expressing rhodopsin and an outer-membrane conduit MtrCAB[95]

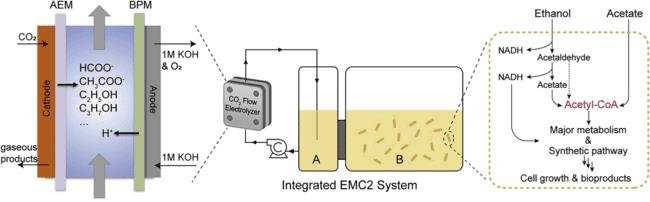

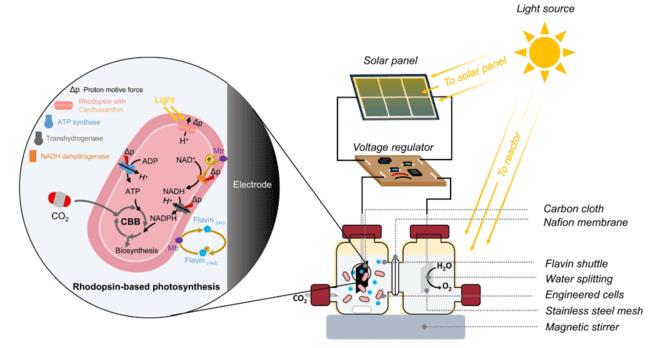

Fig. 14 Schematic of the spatially separated electrochemical CO2 reduction reaction (CO2RR) and microbial fermentation process for efficient β-farnesene synthesis from CO2[98]

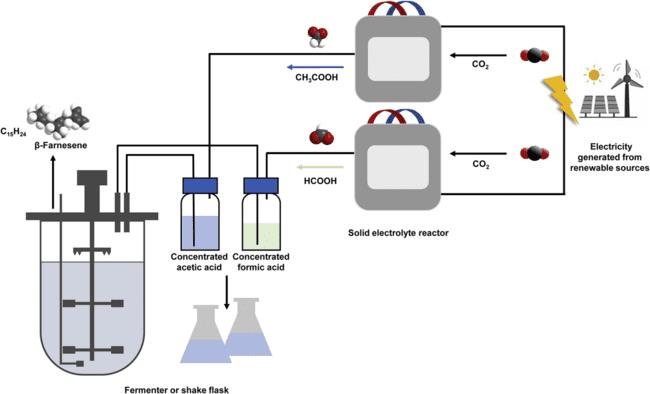

Fig. 16 Schematic illustration of L-tyrosine synthesis from CO2 using a blended nexus molecular system based on an abiotic/biotic cascade catalysis[105]

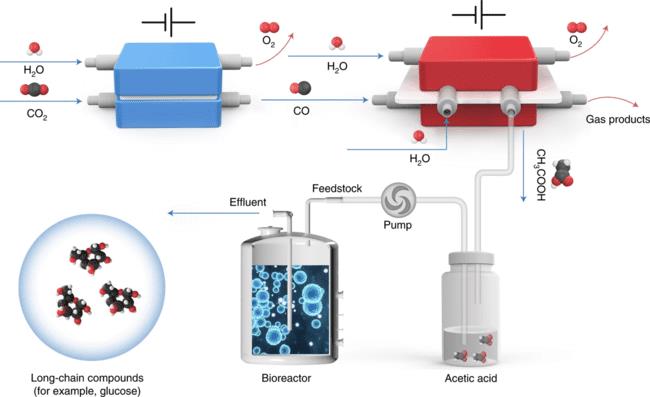

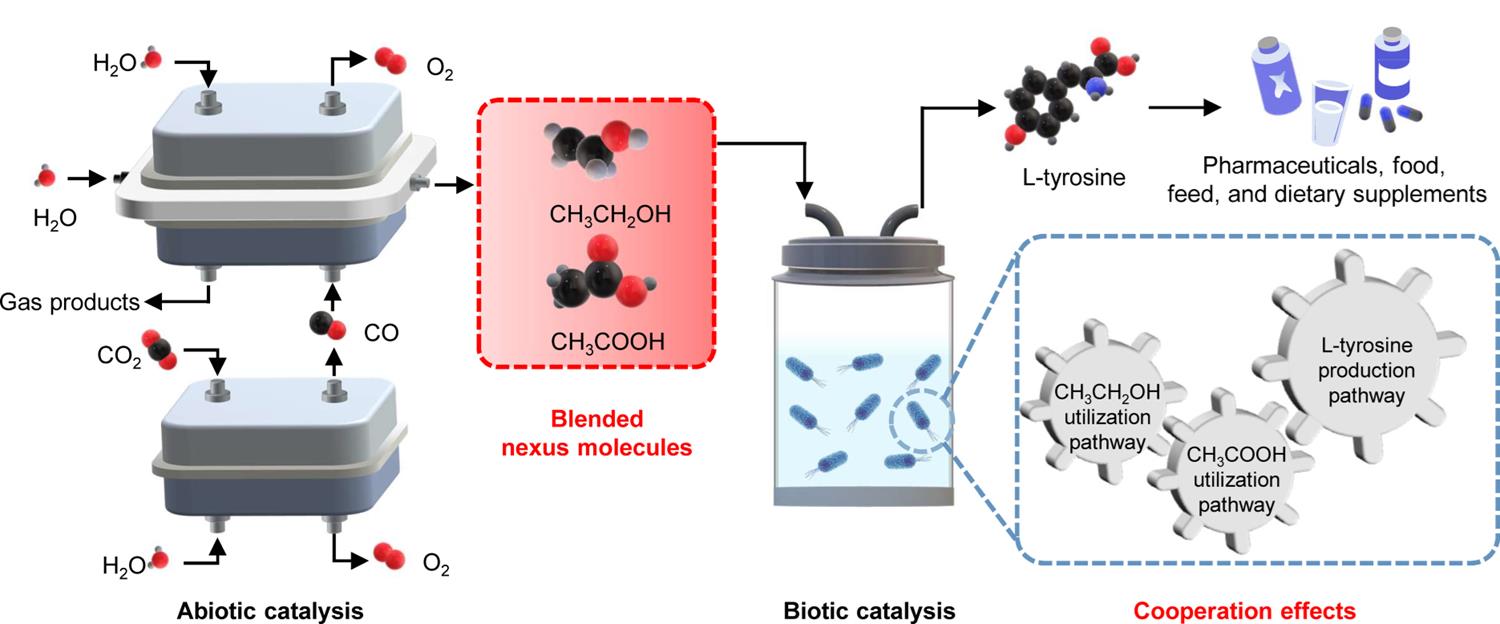

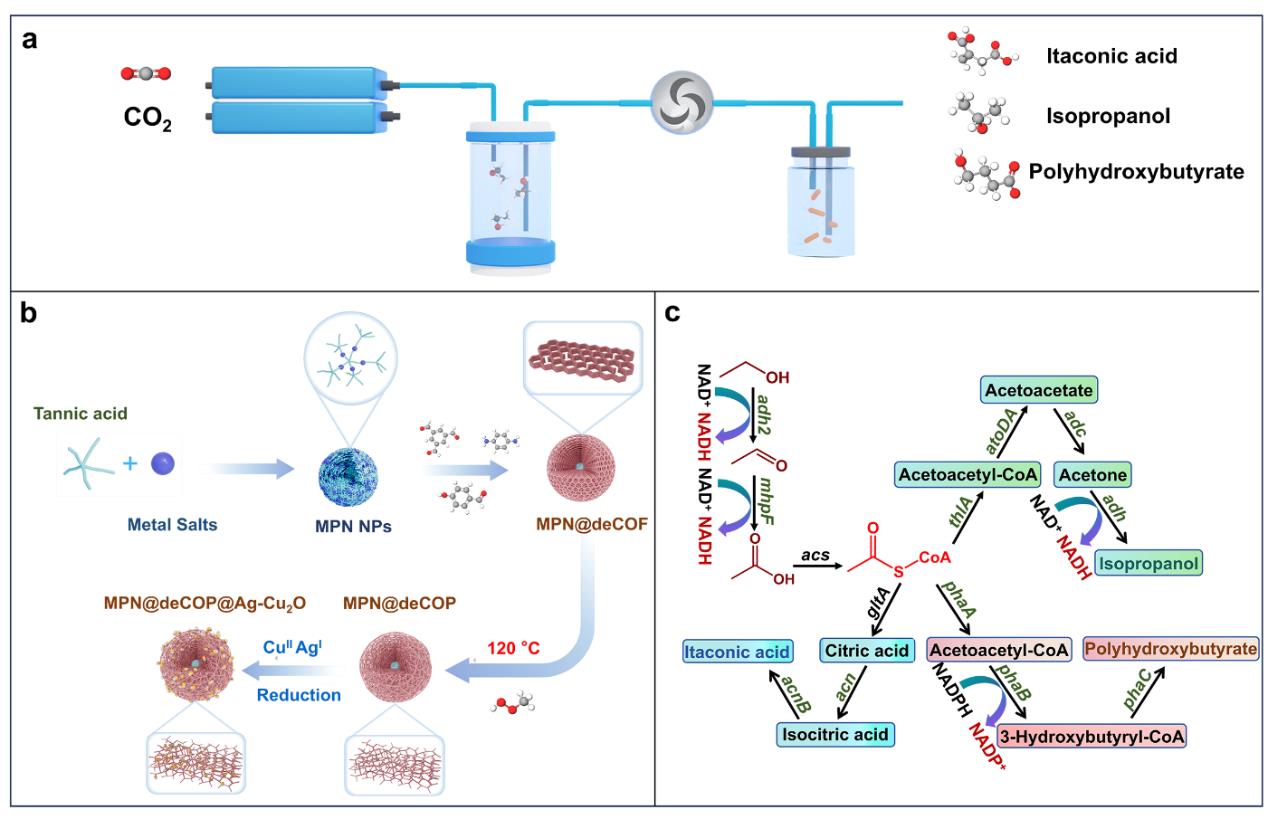

Fig. 17 Schematic diagram of the carbon dioxide electrocatalytic platform and microbial conversion for long-chain compound synthesis. a) Schematic illustration of the integrated electrocatalytic/biocatalytic platform system for the synthesis of long-chain compounds from CO2. b) Schematic depiction of the fabrication process of the MPN@deCOP@Ag-Cu2O electrocatalytic platform. c) Construction of the ethanol utilization pathway[106].

| 产物种类 | 电极材料或者催化剂种类 | 细菌种类 | 产量 | 生成速率 | 参考文献 | |

|---|---|---|---|---|---|---|

| 原位耦合体系 | 甲烷 | Co-N4@Co-NP | 电活性产甲烷混菌 | —— | 3860 mmol/(m2·day) | [ |

| C2+ | CNTs增强的中空纤维膜 | 活性污泥中的微生物种群(Macellibacteroides为) | 乙酸产量达230 mg/L,乙醇最高浓度达7.05 mg/L | —— | [ | |

PHB | 亲水导电聚合物络合物涂敷的碳毡 | —— | [ | |||

| 异丙醇 | 钴基催化剂 | R. eutropha | 216 | 43.2 | [ | |

| 乙酸 | 大孔网状玻璃碳电极 | Acetoanaerobium, Hydrogenophaga, Methanobrevibacter, one New Reference_OTU | —— | 1330 g/(m2·d) | [ | |

| 番茄红素 | —— | C. necator | 1.73 mg/L | —— | [ | |

| α-石竹烯 | —— | R. eutropha | 10.8 ± 2.5 mg/L | 0.08 ± 0.01 mg/(L·h) | [ | |

| 甲酸 | —— | S. oneidensis | —— | 3.50 mmol/(L·μg protein) | [ | |

| 异位耦合体系 | 高级醇(异丁醇和3-甲基-1-丁醇) | Pt阴极 | R. eutropha | 846 mg/L异丁醇和570 mg/L 3-甲基-1-丁醇 | —— | [ |

| PHA | Cu/PTFE | P. putida | 556.2 mg/L | 2.75 g/L DCW | [ | |

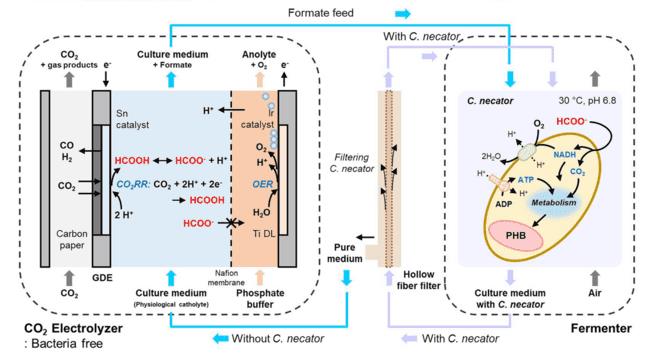

| PHB | Sn | Cupriavidus | 1.38 g | 11.5 mg/h | [ | |

| β-法尼烯 | Ni-N-C | Y. lipolytica | —— | 14.8±0.23 g/L | [ | |

| PHB | Bi2O3纳米片 | R. eutropha | —— | 99.6 mg/(L·d) | [ |

Table 1 Representative work: in situ vs ex situ coupling

| 产物种类 | 电极材料或者催化剂种类 | 细菌种类 | 产量 | 生成速率 | 参考文献 | |

|---|---|---|---|---|---|---|

| 原位耦合体系 | 甲烷 | Co-N4@Co-NP | 电活性产甲烷混菌 | —— | 3860 mmol/(m2·day) | [ |

| C2+ | CNTs增强的中空纤维膜 | 活性污泥中的微生物种群(Macellibacteroides为) | 乙酸产量达230 mg/L,乙醇最高浓度达7.05 mg/L | —— | [ | |

PHB | 亲水导电聚合物络合物涂敷的碳毡 | —— | [ | |||

| 异丙醇 | 钴基催化剂 | R. eutropha | 216 | 43.2 | [ | |

| 乙酸 | 大孔网状玻璃碳电极 | Acetoanaerobium, Hydrogenophaga, Methanobrevibacter, one New Reference_OTU | —— | 1330 g/(m2·d) | [ | |

| 番茄红素 | —— | C. necator | 1.73 mg/L | —— | [ | |

| α-石竹烯 | —— | R. eutropha | 10.8 ± 2.5 mg/L | 0.08 ± 0.01 mg/(L·h) | [ | |

| 甲酸 | —— | S. oneidensis | —— | 3.50 mmol/(L·μg protein) | [ | |

| 异位耦合体系 | 高级醇(异丁醇和3-甲基-1-丁醇) | Pt阴极 | R. eutropha | 846 mg/L异丁醇和570 mg/L 3-甲基-1-丁醇 | —— | [ |

| PHA | Cu/PTFE | P. putida | 556.2 mg/L | 2.75 g/L DCW | [ | |

| PHB | Sn | Cupriavidus | 1.38 g | 11.5 mg/h | [ | |

| β-法尼烯 | Ni-N-C | Y. lipolytica | —— | 14.8±0.23 g/L | [ | |

| PHB | Bi2O3纳米片 | R. eutropha | —— | 99.6 mg/(L·d) | [ |

| 原位耦合系统 | 异位耦合系统 | |

|---|---|---|

| 固碳位点 | 微生物胞内 | 人工电极表面 |

| 生物-非生物偶联方式 | 直接/间接电子转移 | 通过含碳中间体转移 |

| 产物选择性 | 较高 | 较高 |

| 运行稳定性 | 较差 | 较好 |

| 放大可行性 | 较难 | 较易 |

Table 2 Comparative analysis of in situ and ex situ coupling systems

| 原位耦合系统 | 异位耦合系统 | |

|---|---|---|

| 固碳位点 | 微生物胞内 | 人工电极表面 |

| 生物-非生物偶联方式 | 直接/间接电子转移 | 通过含碳中间体转移 |

| 产物选择性 | 较高 | 较高 |

| 运行稳定性 | 较差 | 较好 |

| 放大可行性 | 较难 | 较易 |

| [1] | YAN T X, CHEN X Y, KUMARI L, et al. Multiscale CO2 electrocatalysis to C2+ products: Reaction mechanisms, catalyst design, and device fabrication [J]. Chemical Reviews, 2023, 123(17): 10530-10583. |

| [2] | NAGARAJAN P, AUGUSTINE I J, ROSS M B. Strategies for multi-step carbon dioxide upgrading and valorization [J]. Cell Reports Physical Science, 2023, 4(7): 101472. |

| [3] | WANG Q, ZHANG J F, DAI Q L, et al. When green carbon plants meet synthetic biology [J]. Modern Agriculture, 2023, 1(2): 98-111. |

| [4] | QIAO J L, LIU Y Y, HONG F, et al. A review of catalysts for the electroreduction of carbon dioxide to produce low-carbon fuels [J]. Chemical Society Reviews, 2014, 43(2): 631-675. |

| [5] | NITOPI S, BERTHEUSSEN E, SCOTT B S, et al. Progress and perspectives of electrochemical CO2 reduction on copper in aqueous electrolyte [J]. Chemical Reviews, 2019, 119(12): 7610-7672. |

| [6] | SUN Y, LUO Z H, QIU J S. Breakthrough in CO2 electroreduction to multi‐carbon products at ampere‐level enabled by active sites engineering [J]. Angewandte Chemie International Edition, 2024, 136(38): e202406879. |

| [7] | SHUBA E S, KIFLE D. Microalgae to biofuels: 'Promising' alternative and renewable energy, review [J]. Renewable and Sustainable Energy Reviews, 2018, 81: 743-755. |

| [8] | POUREBRAHIMI S, PIROOZ M, AHMADI S, et al. Nanoengineering of metal-based electrocatalysts for carbon dioxide (CO2) reduction: A critical review [J]. Materials Today Physics, 2023, 38: 101250. |

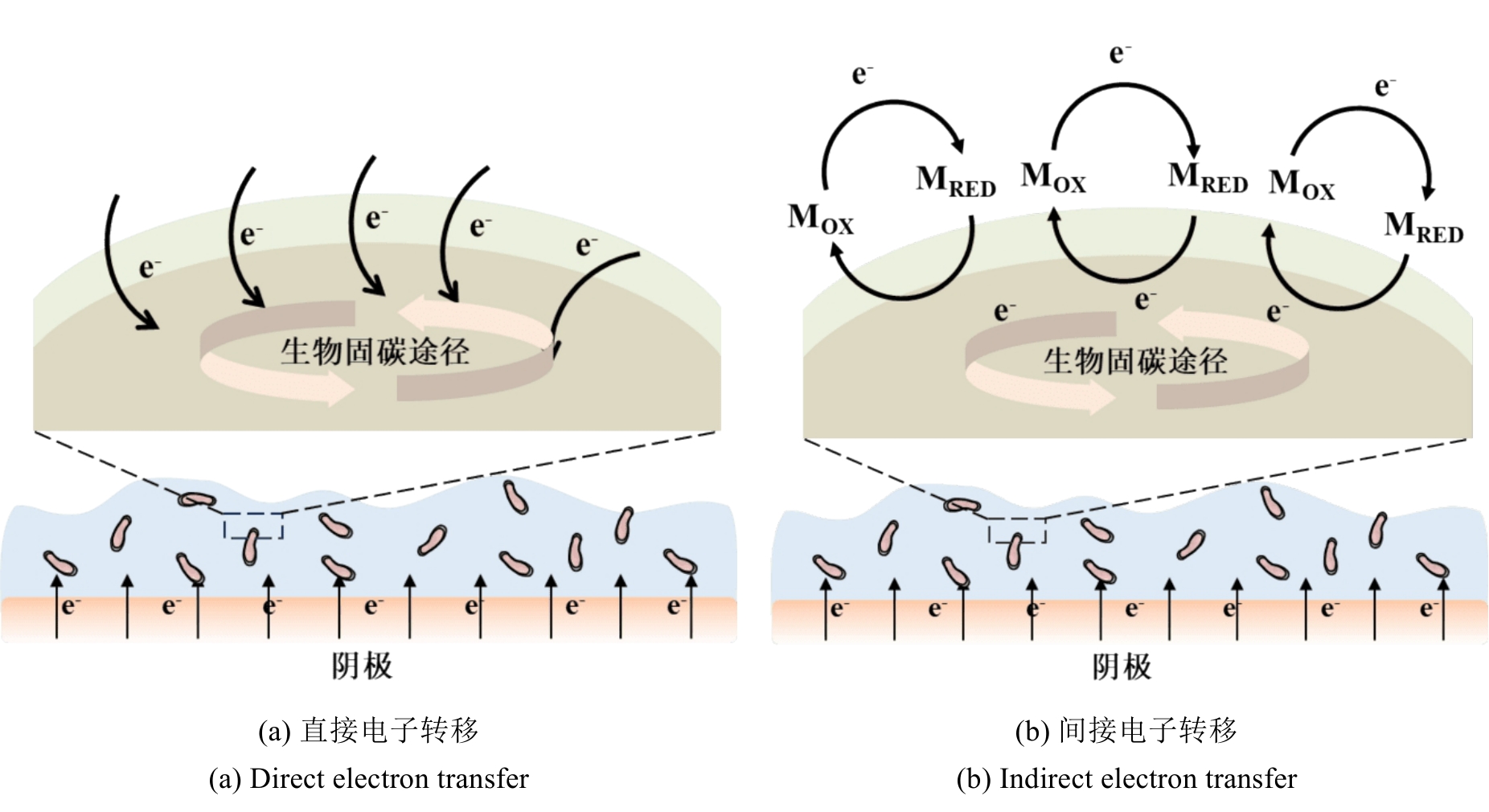

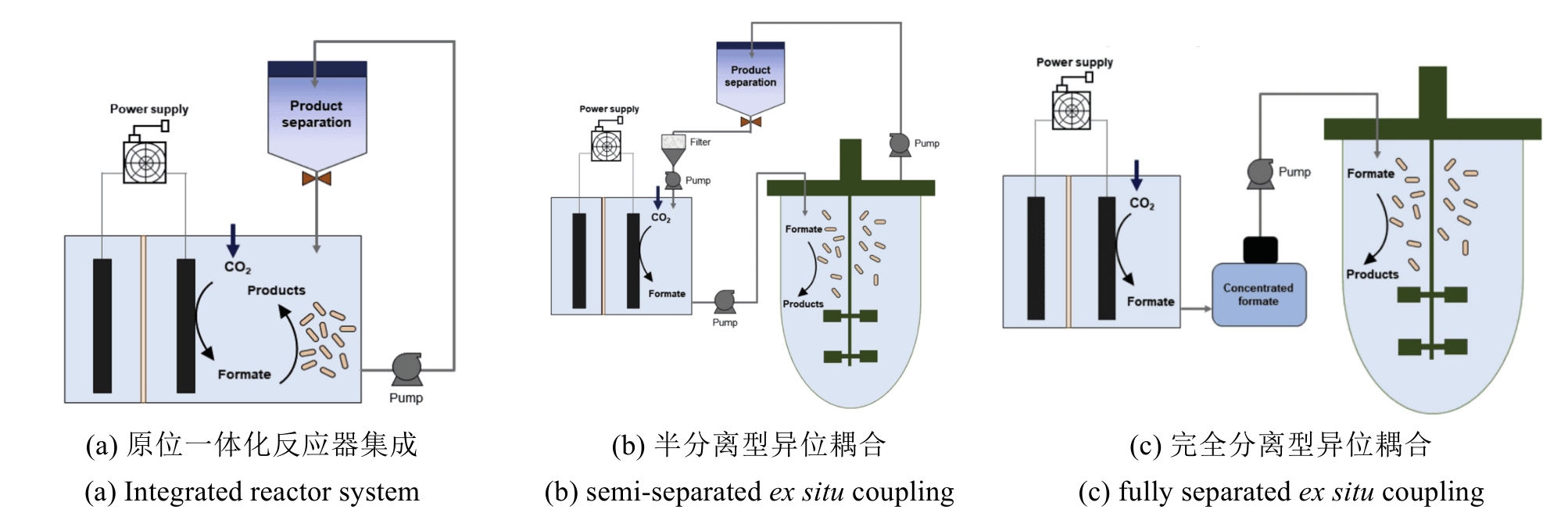

| [9] | IZADI P, HARNISCH F. Microbial | electrochemical CO2 reduction: To integrate or not to integrate? [J]. Joule, 2022, 6(5): 935-940. |

| [10] | TAN X Y, NIELSEN J. The integration of bio-catalysis and electrocatalysis to produce fuels and chemicals from carbon dioxide [J]. Chemical Society Reviews, 2022, 51(11): 4763-4785. |

| [11] | ZHANG S X, JIANG J W, WANG H N, et al. A review of microbial electrosynthesis applied to carbon dioxide capture and conversion: The basic principles, electrode materials, and bioproducts [J]. Journal of CO2 Utilization, 2021, 51: 101640. |

| [12] | MOSCOVIZ R, TOLEDO-ALARCóN J, TRABLY E, et al. Electro-fermentation: How to drive fermentation using electrochemical systems [J]. Trends in Biotechnology, 2016, 34(11): 856-865. |

| [13] | LUAN L K, JI X L, GUO B X, et al. Bioelectrocatalysis for CO2 reduction: recent advances and challenges to develop a sustainable system for CO2 utilization [J]. Biotechnology Advances, 2023, 63: 108098. |

| [14] | MAUREIRA D, ROMERO O, ILLANES A, et al. Industrial bioelectrochemistry for waste valorization: State of the art and challenges [J]. Biotechnology Advances, 2023, 64: 108123. |

| [15] | YU Y Y, WANG Y Z, FANG Z, et al. Single cell electron collectors for highly efficient wiring-up electronic abiotic/biotic interfaces [J]. Nature Communication, 2020, 11(1): 4087. |

| [16] | RABAEY K, ROZENDAL R A. Microbial electrosynthesis-revisiting the electrical route for microbial production [J]. Nature Review Microbiology, 2010, 8(10): 706-716. |

| [17] | FLEXER V, JOURDIN L. Purposely designed hierarchical porous electrodes for high rate microbial electrosynthesis of acetate from carbon dioxide [J]. Accounts of Chemical Research, 2020, 53(2): 311-321. |

| [18] | TAHIR K, MIRAN W, JANG J, et al. MXene-coated biochar as potential biocathode for improved microbial electrosynthesis system [J]. Science of The Total Environment, 2021, 773: 145677. |

| [19] | NIE H R, ZHANG T, CUI M M, et al. Improved cathode for high efficient microbial-catalyzed reduction in microbial electrosynthesis cells [J]. Physical Chemistry Chemical Physics, 2013, 15(34): 14290. |

| [20] | CUI M M, NIE H R, ZHANG T, et al. Three-dimensional hierarchical metal oxide-carbon electrode materials for highly efficient microbial electrosynthesis [J]. Sustainable Energy & Fuels, 2017, 1(5): 1171-1176. |

| [21] | XIA R X, CHENG J, CHEN Z, et al. Tailoring interfacial microbiome and charge dynamics via a rationally designed atomic-nanoparticle bridge for bio-electrochemical CO2-fixation [J]. Energy & Environmental Science, 2023, 16(3): 1176-1186. |

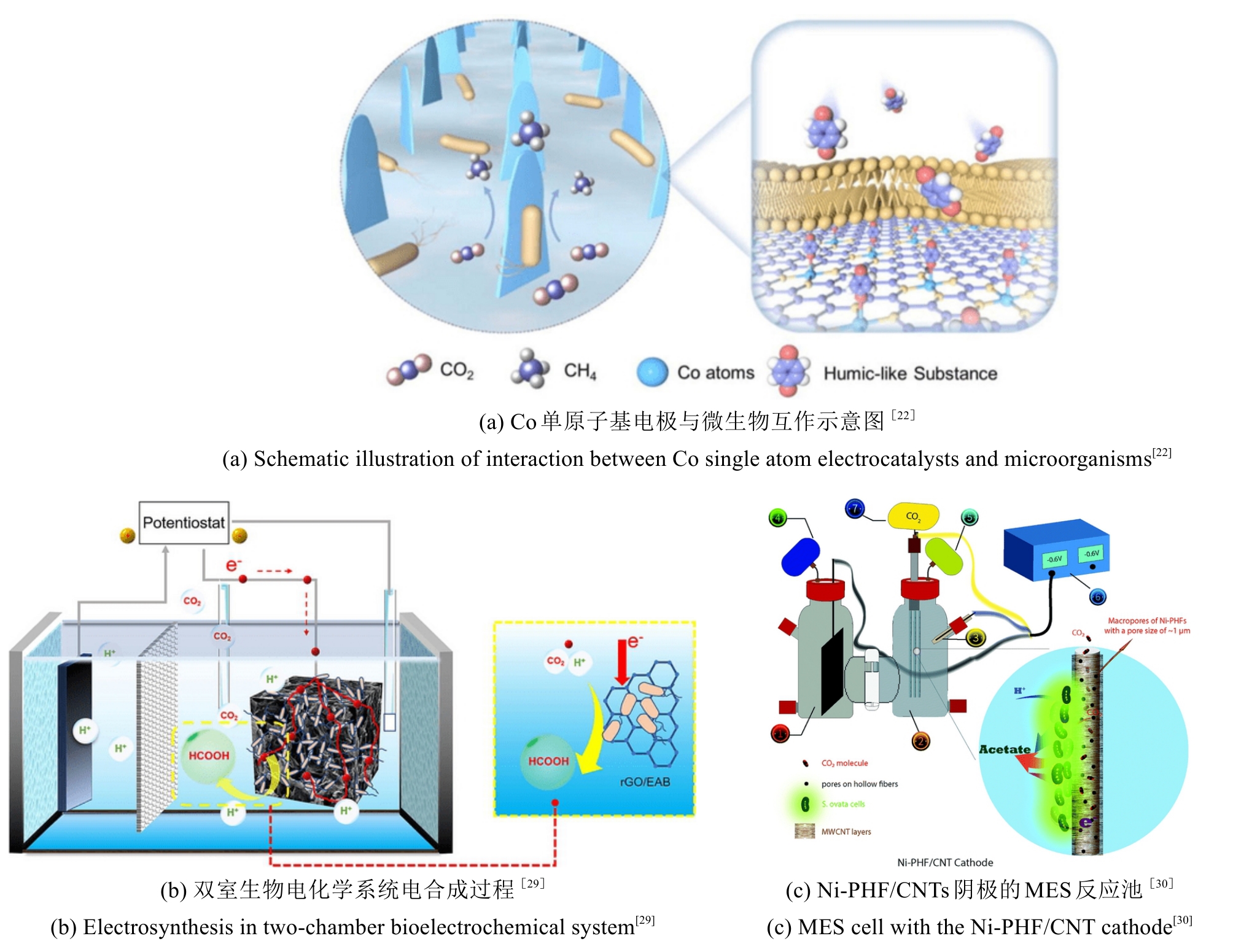

| [22] | XIA R X, FANG Y S, CHEN Z, et al. Manipulating electron extraction efficiency in microbial electrochemical carbon fixation via single-atom engineering [J]. Materials Today, 2023, 68: 51-61. |

| [23] | XIA R X, CHENG J, CHEN Z, et al. Revealing Co-N4@Co-NP bridge-enabled fast charge transfer and active intracellular methanogenesis in bio-electrochemical CO2-conversion with Methanosarcina Barkeri [J]. Advanced Materials, 2023, 35(52): 2304920. |

| [24] | ARYAL N, HALDER A, P-L TREMBLAY, et al. Enhanced microbial electrosynthesis with three-dimensional graphene functionalized cathodes fabricated via solvothermal synthesis [J]. Electrochimica Acta, 2016, 217: 117-122. |

| [25] | LI Q, FU Q, KOBAYASHI H, et al. GO/PEDOT modified biocathodes promoting CO2 reduction to CH4 in microbial electrosynthesis [J]. Sustainable Energy & Fuels, 2020, 4(6): 2987-2997. |

| [26] | JOURDIN L, GRIEGER T, MONETTI J, et al. High acetic acid production rate obtained by microbial electrosynthesis from carbon dioxide [J]. Environmental Science & Technology, 2015, 49(22): 13566-13574. |

| [27] | YU L P, YUAN Y, TANG J H, et al. Thermophilic Moorella thermoautotrophica-immobilized cathode enhanced microbial electrosynthesis of acetate and formate from CO2 [J]. Bioelectrochemistry, 2017, 117: 23-28. |

| [28] | ZHANG T, NIE H R, BAIN T S, et al. Improved cathode materials for microbial electrosynthesis [J]. Energy & Environmental Science, 2013, 6(1): 217-224. |

| [29] | CHEN H, LI J W, FAN Q C, et al. A feasible strategy for microbial electrocatalytic CO2 reduction via whole-cell-packed and exogenous-mediator-free rGO/Shewanella biohydrogel [J]. Chemical Engineering Journal, 2023, 460: 141863. |

| [30] | BIAN B, ALQAHTANI M F, KATURI K P, et al. Porous nickel hollow fiber cathodes coated with CNTs for efficient microbial electrosynthesis of acetate from CO2 using Sporomusa ovata [J]. Journal of Materials Chemistry A, 2018, 6(35): 17201-17211. |

| [31] | FU S F, ANGELIDAKI I, ZHANG Y F. In situ biogas upgrading by CO2-to-CH4 bioconversion [J]. Trends in Biotechnology, 2021, 39(4): 336-347. |

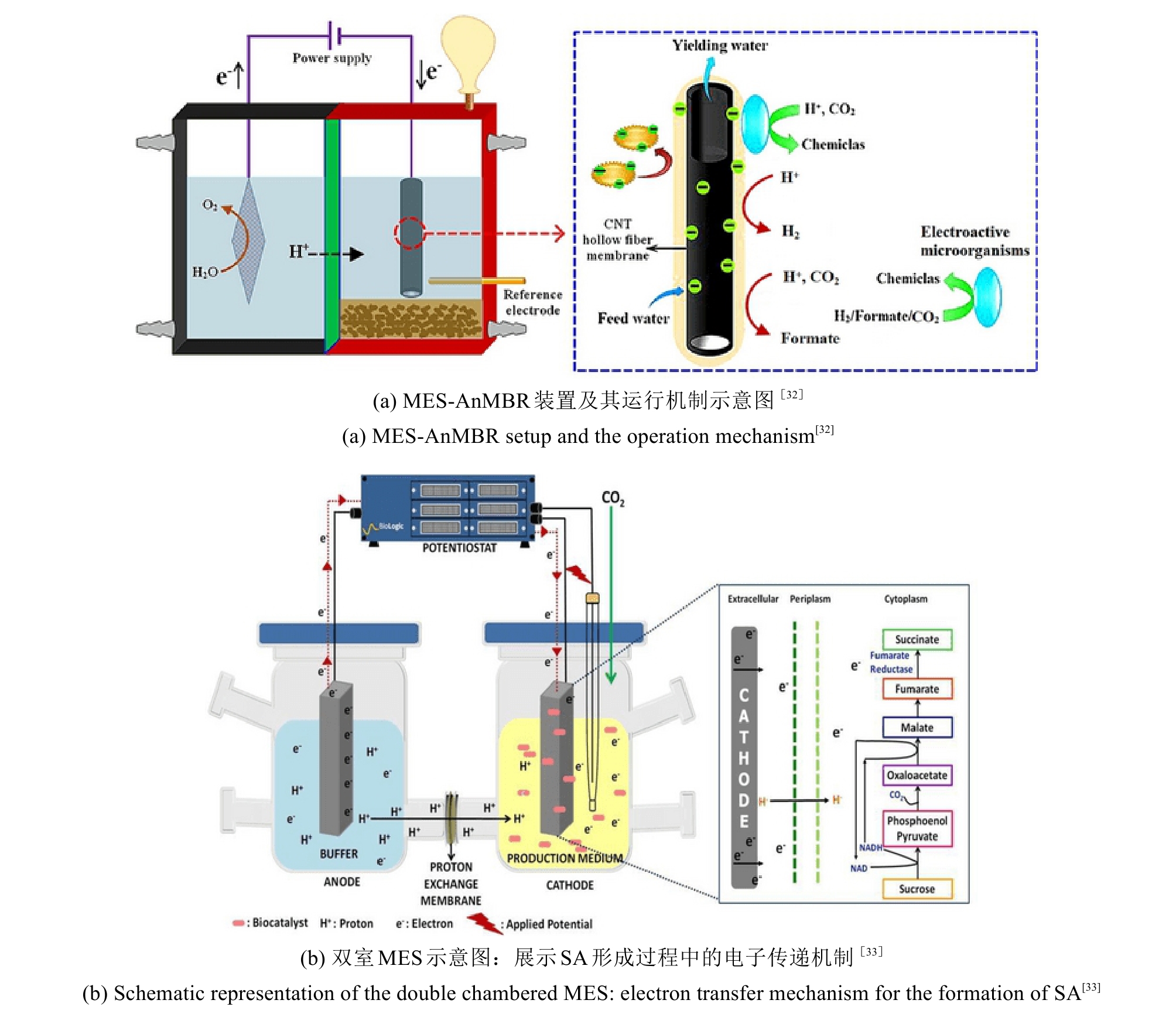

| [32] | YANG Y, JI Z X, ZHOU J T, et al. Production of C2+ products in novel microbial electrosynthesis coupled with anaerobic membrane bioreactor [J]. Chemical Engineering Journal, 2023, 476: 146328. |

| [33] | AMULYA K, VENKATA MOHAN S. Augmenting succinic acid production by bioelectrochemical synthesis: Influence of applied potential and CO2 availability [J]. Chemical Engineering Journal, 2021, 411: 128377. |

| [34] | NEVIN K P, WOODARD T L, FRANKS A E, et al. Microbial electrosynthesis: Feeding microbes electricity to convert carbon dioxide and water to multicarbon extracellular organic compounds [J]. mBio, 2010, 1(2): e00103-10. |

| [35] | ARYAL N, P-L TREMBLAY, LIZAK D M, et al. Performance of different Sporomusa species for the microbial electrosynthesis of acetate from carbon dioxide [J]. Bioresource Technology, 2017, 233: 184-90. |

| [36] | LABELLE E V, MARSHALL C W, MAY H D. Microbiome for the electrosynthesis of chemicals from carbon dioxide [J]. Accounts of Chemical Research, 2020, 53(1): 62-71. |

| [37] | THARAK A, KATAKOJWALA R, KAJLA S, et al. Chemolithoautotrophic reduction of CO2 to acetic acid in gas and gas-electro fermentation systems: Enrichment, microbial dynamics, and sustainability assessment [J]. Chemical Engineering Journal, 2023, 454: 140200. |

| [38] | MAYER F, ENZMANN F, LOPEZ A M, et al. Performance of different methanogenic species for the microbial electrosynthesis of methane from carbon dioxide [J]. Bioresource Technology, 2019, 289: 121706. |

| [39] | LIU C Q, XIAO J W, LI H Y, et al. High efficiency in-situ biogas upgrading in a bioelectrochemical system with low energy input [J]. Water Research, 2021, 197: 117055. |

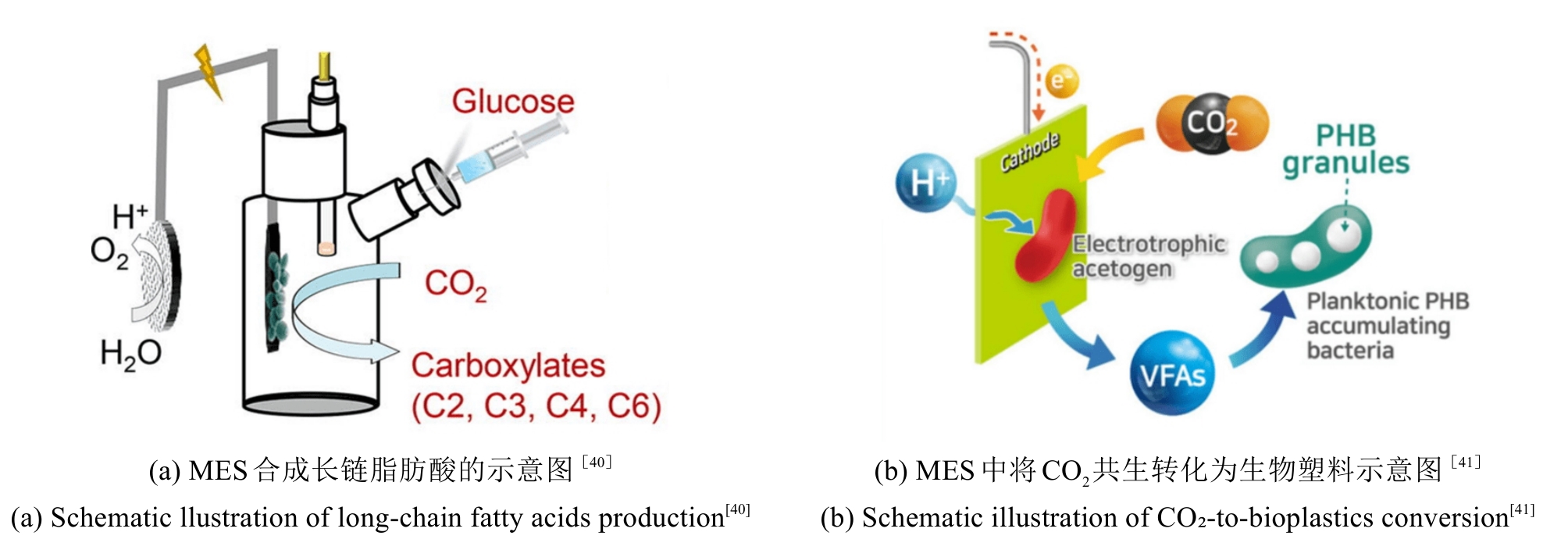

| [40] | WANG D L, LIANG Q J, CHU N, et al. Deciphering mixotrophic microbial electrosynthesis with shifting product spectrum by genome-centric metagenomics [J]. Chemical Engineering Journal, 2023, 451: 139010. |

| [41] | LE G T H, MOHAMED H O, KIM H, et al. Microbial symbiotic electrobioconversion of carbon dioxide to biopolymer (poly (3-hydroxybutyrate)) via single-step microbial electrosynthesis cell [J]. Chemical Engineering Journal, 2024, 500: 156635. |

| [42] | SHI X C, TREMBLAY P L, WAN L L, et al. Improved robustness of microbial electrosynthesis by adaptation of a strict anaerobic microbial catalyst to molecular oxygen [J]. Science of The Total Environment, 2021, 754: 142440. |

| [43] | ROSENBAUM M, AULENTA F, VILLANO M, et al. Cathodes as electron donors for microbial metabolism: which extracellular electron transfer mechanisms are involved? [J]. Bioresource Technology, 2011, 102(1): 324-333. |

| [44] | JIANG Y, ZENG R J. Expanding the product spectrum of value added chemicals in microbial electrosynthesis through integrated process design-A review [J]. Bioresource Technology, 2018, 269: 503-512. |

| [45] | FENG Y H, XU M Y, P-L TREMBLAY, et al. The one-pot synthesis of a ZnSe/ZnS photocatalyst for H2 evolution and microbial bioproduction [J]. International Journal of Hydrogen Energy, 2021, 46(42): 21901-21911. |

| [46] | NICHOLS E M, GALLAGHER J J, LIU C, et al. Hybrid bioinorganic approach to solar-to-chemical conversion [J]. Proceedings of the National Academy of Sciences, 2015, 112(37): 11461-11466. |

| [47] | P-L TREMBLAY, XU M Y, CHEN Y M, et al. Nonmetallic abiotic-biological hybrid photocatalyst for visible water splitting and carbon dioxide reduction [J]. iScience, 2020, 23(1): 100784. |

| [48] | TIAN S H, WANG H Q, DONG Z W, et al. Mo2C-induced hydrogen production enhances microbial electrosynthesis of acetate from CO2 reduction [J]. Biotechnology for Biofuels, 2019, 12(1): 71. |

| [49] | TORELLA J P, GAGLIARDI C J, CHEN J S, et al. Efficient solar-to-fuels production from a hybrid microbial-water-splitting catalyst system [J]. Proceedings of the National Academy of Sciences, 2015, 112(8): 2337-2342. |

| [50] | CHONG LIU, COLóN B C, ZIESACK M, et al. Water splitting-biosynthetic system with CO2 reduction efficiencies exceeding photosynthesis [J]. Science, 2016, 352(6290): 1210-1213. |

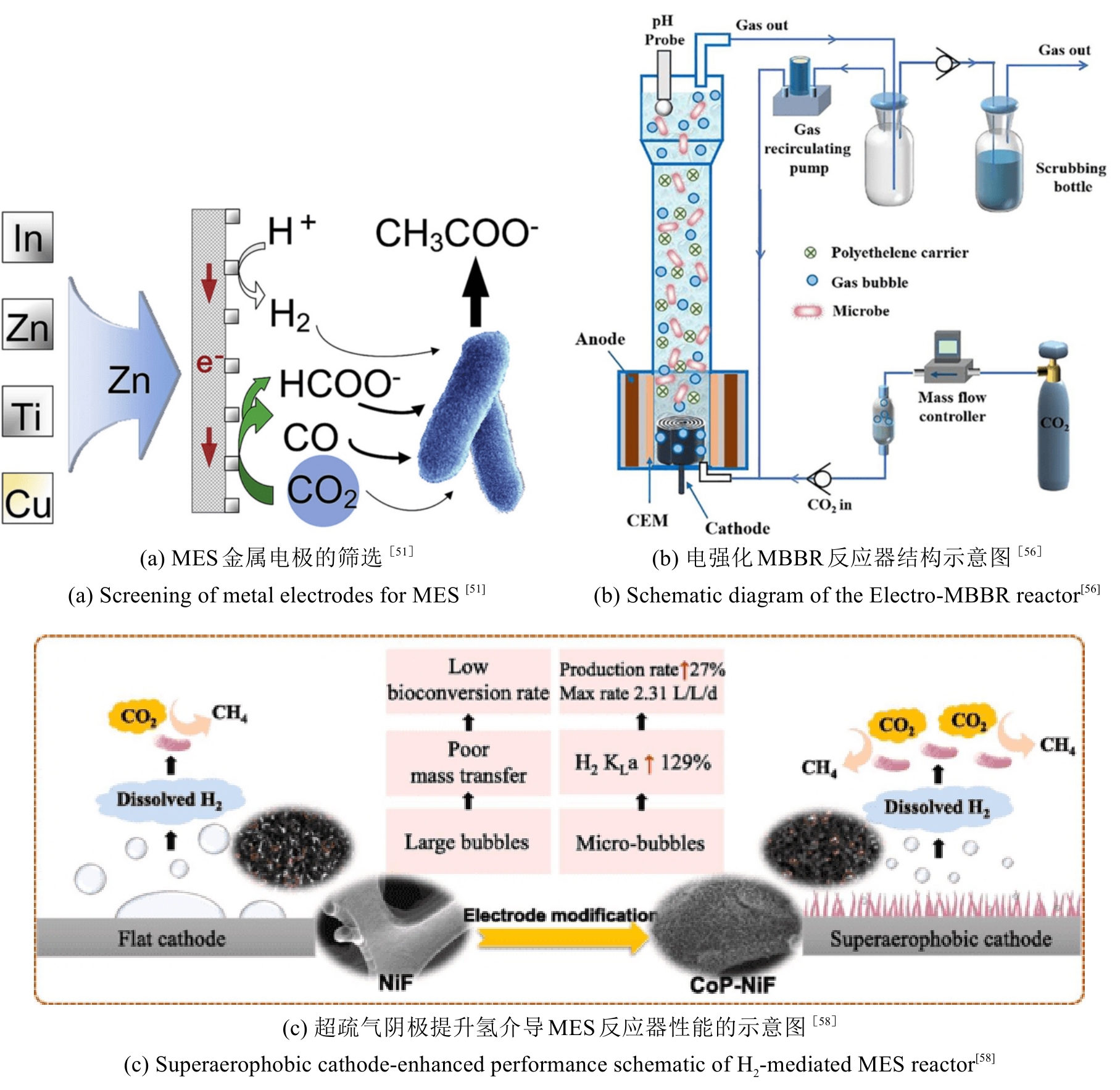

| [51] | JIANG Y, CHU N, ZHANG W, et al. Zinc: A promising material for electrocatalyst-assisted microbial electrosynthesis of carboxylic acids from carbon dioxide [J]. Water Research, 2019, 159: 87-94. |

| [52] | IZADI P, J-M FONTMORIN, LIM S S, et al. Enhanced bio-production from CO2 by microbial electrosynthesis (MES) with continuous operational mode [J]. Faraday Discussions, 2021, 230: 344-359. |

| [53] | ARYAL N, WAN L L, OVERGAARD M H, et al. Increased carbon dioxide reduction to acetate in a microbial electrosynthesis reactor with a reduced graphene oxide-coated copper foam composite cathode [J]. Bioelectrochemistry, 2019, 128: 83-93. |

| [54] | JIANG Y, LIANG Q J, CHU N, et al. A slurry electrode integrated with membrane electrolysis for high-performance acetate production in microbial electrosynthesis [J]. Science of The Total Environment, 2020, 741: 140198. |

| [55] | ROHBOHM N, SUN T, BLASCO-GóMEZ R, et al. Carbon oxidation with sacrificial anodes to inhibit O2 evolution in membrane-less bioelectrochemical systems for microbial electrosynthesis [J]. EES Catalysis, 2023, 1(6): 972-986. |

| [56] | CAI W F, CUI K, LIU Z Z, et al. An electrolytic-hydrogen-fed moving bed biofilm reactor for efficient microbial electrosynthesis of methane from CO2 [J]. Chemical Engineering Journal, 2022, 428: 132093. |

| [57] | BAJRACHARYA S, KRIGE A, MATSAKAS L, et al. Dual cathode configuration and headspace gas recirculation for enhancing microbial electrosynthesis using Sporomusa ovata [J]. Chemosphere, 2022, 287: 132188. |

| [58] | GAO J Y, CAI W F, BAI J R, et al. Strengthening H2 gas-liquid mass transfer using superaerophobic cathodes for enhanced methane production from CO2 in H2-mediated microbial electrosynthesis system [J]. Bioresource Technology, 2025, 417: 131850. |

| [59] | RODRIGUES R M, GUAN X, IñIGUEZ J A, et al. Perfluorocarbon nanoemulsion promotes the delivery of reducing equivalents for electricity-driven microbial CO2 reduction [J]. Nature Catalysis, 2019, 2(5): 407-414. |

| [60] | BAJRACHARYA S, HEIJNE A TER, DOMINGUEZ BENETTON X, et al. Carbon dioxide reduction by mixed and pure cultures in microbial electrosynthesis using an assembly of graphite felt and stainless steel as a cathode [J]. Bioresource Technology, 2015, 195: 14-24. |

| [61] | BAJRACHARYA S, VANBROEKHOVEN K, BUISMAN C J N, et al. Bioelectrochemical conversion of CO2 to chemicals: CO2 as a next generation feedstock for electricity-driven bioproduction in batch and continuous modes [J]. Faraday Discussions, 2017, 202: 433-449. |

| [62] | VELVIZHI G, SARKAR O, ROVIRA-ALSINA L, et al. Conversion of carbon dioxide to value added products through anaerobic fermentation and electro fermentation: A comparative approach [J]. International Journal of Hydrogen Energy, 2022, 47(34): 15442-15455. |

| [63] | CHU W J, WU Z Y, LI X H, et al. Reduction short-chain volatile fatty acids and CO2 into alcohols in microbial electrosynthesis system [J]. Renewable Energy, 2024, 237: 121751. |

| [64] | BATLLE-VILANOVA P, PUIG S, GONZALEZ-OLMOS R, et al. Continuous acetate production through microbial electrosynthesis from CO2 with microbial mixed culture [J]. Journal of Chemical Technology & Biotechnology, 2015, 91(4): 921-927. |

| [65] | XIAO S, FU Q, XIONG K R, et al. Parametric study of biocathodes in microbial electrosynthesis for CO2 reduction to CH4 with a direct electron transfer pathway [J]. Renewable Energy, 2020, 162: 438-446. |

| [66] | BLANCHET E, DUQUENNE F, RAFRAFI Y, et al. Importance of the hydrogen route in up-scaling electrosynthesis for microbial CO2 reduction [J]. Energy & Environmental Science, 2015, 8(12): 3731-3744. |

| [67] | JOURDIN L, FREGUIA S, FLEXER V, et al. Bringing high-rate, CO2-based microbial electrosynthesis closer to practical implementation through improved electrode design and operating conditions [J]. Environmental Science & Technology, 2016, 50(4): 1982-1989. |

| [68] | ROY M, YADAV R, CHIRANJEEVI P, et al. Direct utilization of industrial carbon dioxide with low impurities for acetate production via microbial electrosynthesis [J]. Bioresource Technology, 2021, 320: 124289. |

| [69] | AMMAM F, P-L TREMBLAY, LIZAK D M, et al. Effect of tungstate on acetate and ethanol production by the electrosynthetic bacterium Sporomusa ovata [J]. Biotechnology for Biofuels, 2016, 9(1): 163. |

| [70] | VILLANO M, AULENTA F, CIUCCI C, et al. Bioelectrochemical reduction of CO2 to CH4 via direct and indirect extracellular electron transfer by a hydrogenophilic methanogenic culture [J]. Bioresource Technology, 2010, 101(9): 3085-3090. |

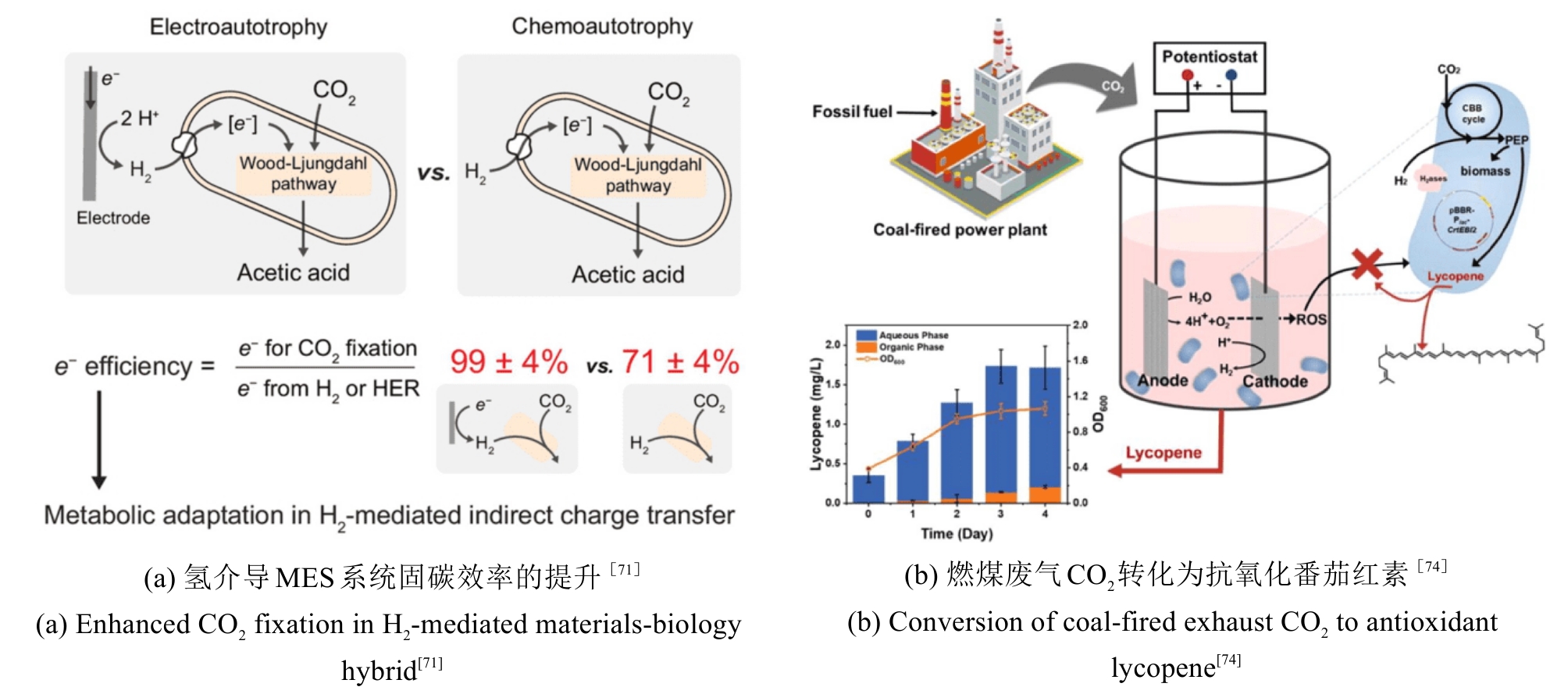

| [71] | XIE Y C, ERŞAN S, GUAN X, et al. Unexpected metabolic rewiring of CO2 fixation in H2-mediated materials-biology hybrids [J]. Proceedings of the National Academy of Sciences, 2023, 120(42): e2308373120. |

| [72] | BOLOGNESI S, BAñERAS L, PERONA-VICO E, et al. Carbon dioxide to bio-oil in a bioelectrochemical system-assisted microalgae biorefinery process [J]. Sustainable Energy & Fuels, 2022, 6(1): 150-161. |

| [73] | DI STADIO G, ORITA I, NAKAMURA R, et al. Gas fermentation combined with water electrolysis for production of polyhydroxyalkanoate copolymer from carbon dioxide by engineered Ralstonia eutropha [J]. Bioresource Technology, 2024, 394: 130266. |

| [74] | WU H L, PAN H J, LI Z J, et al. Efficient production of lycopene from CO2 via microbial electrosynthesis [J]. Chemical Engineering Journal, 2022, 430: 132943. |

| [75] | KRIEG T, SYDOW A, FAUST S, et al. CO2 to terpenes: autotrophic and electroautotrophic α-humulene production with Cupriavidus necator [J]. Angewandte Chemie International Edition, 2018, 57(7): 1879-1882. |

| [76] | STEINBUSCH K J J, HAMELERS H V M, SCHAAP J D, et al. Bioelectrochemical ethanol production through mediated acetate reduction by mixed cultures [J]. Environmental Science & Technology, 2010, 44(1): 513-517. |

| [77] | SONG J, KIM Y, LIM M, et al. Microbes as electrochemical CO2 conversion catalysts [J]. ChemSusChem, 2011, 4(5): 587-590. |

| [78] | SEELAJAROEN H, HABERBAUER M, HEMMELMAIR C, et al. Enhanced bio-electrochemical reduction of carbon dioxide by using neutral red as a redox mediator [J]. ChemBioChem, 2019, 20(9): 1196-1205. |

| [79] | SONG Y E, KIM C, BAEK J, et al. Increased CODH activity in a bioelectrochemical system improves microbial electrosynthesis with CO [J]. Sustainable Energy & Fuels, 2020, 4(12): 5952-5957. |

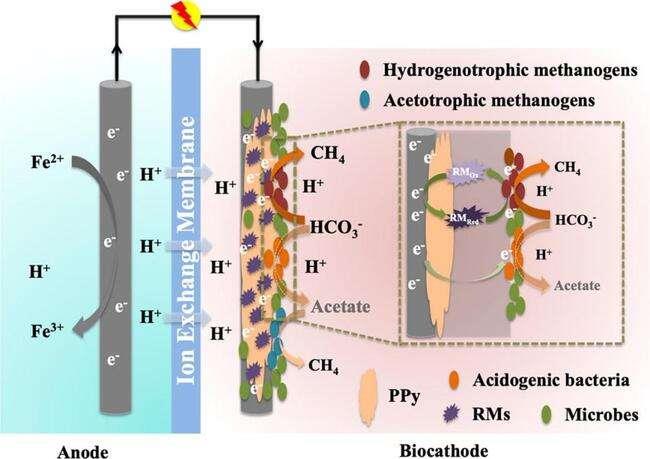

| [80] | YANG H Y, WANG Y X, HE C S, et al. Redox mediator-modified biocathode enables highly efficient microbial electro-synthesis of methane from carbon dioxide [J]. Applied Energy, 2020, 274: 115292. |

| [81] | CHEN H, SIMOSKA O, LIM K, et al. Fundamentals, applications, and future directions of bioelectrocatalysis [J]. Chemical Reviews, 2020, 120(23): 12903-12993. |

| [82] | LUO H P, QI J X, ZHOU M Z, et al. Enhanced electron transfer on microbial electrosynthesis biocathode by polypyrrole-coated acetogens [J]. Bioresource Technology, 2020, 309: 123322. |

| [83] | JOURDIN L, FREGUIA S, DONOSE B C, et al. A novel carbon nanotube modified scaffold as an efficient biocathode material for improved microbial electrosynthesis [J]. Journal of Materials Chemistry A, 2014, 2(32): 13093-13102. |

| [84] | HAN S, LIU H, ZHOU C, et al. Growth of carbon nanotubes on graphene as 3D biocathode for NAD+/NADH balance model and high-rate production in microbial electrochemical synthesis from CO2 [J]. Journal of Materials Chemistry A, 2019, 7(3): 1115-1123. |

| [85] | MA Z S, YANG Z L, LAI W C, et al. CO2 electroreduction to multicarbon products in strongly acidic electrolyte via synergistically modulating the local microenvironment [J]. Nature Communications, 2022, 13(1): 7596. |

| [86] | SONG T S, ZHANG H, LIU H, et al. High efficiency microbial electrosynthesis of acetate from carbon dioxide by a self-assembled electroactive biofilm [J]. Bioresource Technology, 2017, 243: 573-582. |

| [87] | XIA R X, CHENG J, CHEN Z, et al. Atomic pyridinic nitrogen as highly active metal-free coordination sites at the biotic-abiotic interface for bio-electrochemical CO2 reduction [J]. Small, 2023, 20(18): 2306331. |

| [88] | LIU X, HUANG L Y, RENSING C, et al. Syntrophic interspecies electron transfer drives carbon fixation and growth by Rhodopseudomonas palustris under dark, anoxic conditions [J]. Science Advances, 2017, 7: eabh1852. |

| [89] | VU M T, NOORI M T, MIN B. Conductive magnetite nanoparticles trigger syntrophic methane production in single chamber microbial electrochemical systems [J]. Bioresource Technology, 2020, 296: 122265. |

| [90] | LI H, OPGENORTH P H, WERNICK D G, et al. Integrated electromicrobial conversion of CO2 to higher alcohols [J]. Science, 2012, 335(6076): 1596. |

| [91] | CHEN X Y, FENG Q Y, CAI Q H, et al. Mn3O4 nanozyme coating accelerates nitrate reduction and decreases N2O emission during photoelectrotrophic denitrification by Thiobacillus denitrificans-CdS [J]. Environmental Science & Technology, 2020, 54(17): 10820-10830. |

| [92] | CHEN K, MA C L, CHENG X L, et al. Construction of Cupriavidus necator displayed with superoxide dismutases for enhanced growth in bioelectrochemical systems [J]. Bioresources and Bioprocessing, 2023, 10(1): 36. |

| [93] | IM C, VALGEPEA K, MODIN O, et al. Clostridium ljungdahlii as a biocatalyst in microbial electrosynthesis--Effect of culture conditions on product formation [J]. Bioresource Technology Reports, 2022, 19: 101156. |

| [94] | LI Y X, LUO Q L, SU J Y, et al. Metabolic regulation of Shewanella oneidensis for microbial electrosynthesis: From extracellular to intracellular [J]. Metabolic Engineering, 2023, 80: 1-11. |

| [95] | TU W M, XU J B, THOMPSON I P, et al. Engineering artificial photosynthesis based on rhodopsin for CO2 fixation [J]. Nature Communications, 2023, 14(1): 8012. |

| [96] | ZHANG P, CHEN K N, XU B, et al. Chem-bio interface design for rapid conversion of CO2 to bioplastics in an integrated system [J]. Chem, 2022, 8(12): 3363-3381. |

| [97] | LIU X J, ZHANG K, SUN Y D, et al. Upgrading CO2 into acetate on Bi2O3@carbon felt integrated electrode via coupling electrocatalysis with microbial synthesis [J]. Susmat, 2023, 3(2): 235-247. |

| [98] | BI H R, WANG K, XU C C, et al. Biofuel synthesis from carbon dioxide via a bio-electrocatalysis system [J]. Chem Catalysis, 2023, 3(3): 100557. |

| [99] | ZHANG M, CAO A H, XIANG Y C, et al. Strongly coupled Ag/Sn-SnO2 nanosheets toward CO2 electroreduction to pure HCOOH solutions at ampere‑level current [J]. Nano-Micro Letters, 2024, 16: 50. |

| [100] | HAN J Y, BIN T, AN P F, et al. Structuring Cu membrane electrode for maximizing ethylene yield from CO2 electroreduction [J]. Advanced Materials, 2024, 36(21): 2313926. |

| [101] | CUI H J, LIU W S, MA C L, et al. Converting CO2 to single-cell protein via an integrated electrocatalytic-biosynthetic system [J]. Applied Catalysis B: Environment and Energy, 2024, 350: 123946. |

| [102] | LIM J, CHOI S Y, LEE J W, et al. Biohybrid CO2 electrolysis for the direct synthesis of polyesters from CO2 [J]. Proceedings of the National Academy of Sciences, 2023, 120(14): e2221438120. |

| [103] | ZHENG T T, ZHANG M L, WU L H, et al. Upcycling CO2 into energy-rich long-chain compounds via electrochemical and metabolic engineering [J]. Nature Catalysis, 2022, 5(5): 388-396. |

| [104] | ZHANG G R, JI N, LYU S, et al. Artificial synthesis of polyesters at ambient condition via consecutive CO2 electrolysis and fermentation [J]. Nano Research, 2024, 17: 6016-6025. |

| [105] | FAN L, ZHU Z H, ZHAO S Y, et al. Blended nexus molecules promote CO2 to L-tyrosine conversion [J]. Science Advances, 2024, 10(36): eado1352. |

| [106] | HAN L, LI Y, WANG X Y, et al. Spatially Decoupled Electro-Biosystem for Efficient CO2-to-Chemicals Conversion via Tandem Catalysis [J]. Advanced Energy Materials, 2025. |

| [107] | LI C B, GUO M M, YANG B, et al. Efficient and scalable upcycling of oceanic carbon sources into bioplastic monomers [J]. Nature Catalysis, 2025. |

| [1] | HUANG Yuqing, WU Han, LI Xiaobin, LIU Junyu, MA Shaohua, GE Jun, XING Xinhui, ZHANG Canyang. Recent advancements in non-biological component-augmented synthetic bio-hybrid systems [J]. Synthetic Biology Journal, 2025, 6(4): 764-788. |

| [2] | LEI Hangbin, HE Ning, LI Feixuan, DONG Lingling, WANG Shizhen. Advance in the immobilization of hydrogenases [J]. Synthetic Biology Journal, 2024, 5(6): 1485-1497. |

| [3] | HUI Zhen, TANG Xiaoyu. Applications of the CRISPR/Cas9 editing system in the study of microbial natural products [J]. Synthetic Biology Journal, 2024, 5(3): 658-671. |

| [4] | ZHOU Qiang, ZHOU Dawei, SUN Jingxiang, WANG Jingnan, JIANG Wankui, ZHANG Wenming, JIANG Yujia, XIN Fengxue, JIANG Min. Research progress in synthesis of astaxanthin by microbial fermentation [J]. Synthetic Biology Journal, 2024, 5(1): 126-143. |

| [5] | ZHANG Chenyue, MA Yingqun, WANG Xing, FU Rongzhan, HUANG Jiwei, HUA Xiufu, FAN Daidi, FEI Qiang. Progress in the bioconversion of biogas into sustainable aviation fuel [J]. Synthetic Biology Journal, 2023, 4(6): 1246-1258. |

| [6] | LIU Weisong, ZHANG Kuncheng, CUI Huijuan, ZHU Zhiguang, ZHANG Yiheng, ZHANG Lingling. Electro-assisted carbon dioxide biotransformation [J]. Synthetic Biology Journal, 2023, 4(6): 1191-1222. |

| [7] | CHEN Yaru, CAO Yingxiu, SONG Hao. Advances and applications of gene editing and transcriptional regulation in electroactive microorganisms [J]. Synthetic Biology Journal, 2023, 4(6): 1281-1299. |

| [8] | ZHAO Guomiao, YANG Xin, ZHANG Yuan, WANG Jing, TAN Jian, WEI Chao, ZHOU Nana, LI Fan, WANG Xiaoyan. Biofoundry and its industrial application [J]. Synthetic Biology Journal, 2023, 4(5): 892-903. |

| [9] | WANG Yannan, SUN Yuhui. Base editing technology and its application in microbial synthetic biology [J]. Synthetic Biology Journal, 2023, 4(4): 720-737. |

| [10] | CHENG Zhenzhen, ZHANG Jian, GAO Cong, LIU Liming, CHEN Xiulai. Progress in metabolic engineering of microorganisms for the utilization of formate [J]. Synthetic Biology Journal, 2023, 4(4): 756-778. |

| [11] | GAO Xianyun, NIU Lingxue, JIAN Ni, GUAN Ningzi. Applications of microbial synthetic biology in the diagnosis and treatment of diseases [J]. Synthetic Biology Journal, 2023, 4(2): 263-282. |

| [12] | LIU Jianming, ZENG Anping. Cell-free multi-enzyme machines for CO2 capture, utilization and its associated challenges [J]. Synthetic Biology Journal, 2022, 3(5): 825-832. |

| [13] | CUI Xinyu, WU Ranran, WANG Yuanming, ZHU Zhiguang. Construction and enhancement of enzymatic bioelectrocatalytic systems [J]. Synthetic Biology Journal, 2022, 3(5): 1006-1030. |

| [14] | YOU Zixuan, LI Feng, SONG Hao. Design and construction of electroactive cells by synthetic biology strategies [J]. Synthetic Biology Journal, 2022, 3(5): 1031-1059. |

| [15] | ZHAO Quanyu. Research progress in carbon neutrality oriented adaptive laboratory evolution of microalgae [J]. Synthetic Biology Journal, 2022, 3(5): 901-914. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||