Synthetic Biology Journal ›› 2022, Vol. 3 ›› Issue (4): 795-809.DOI: 10.12211/2096-8280.2022-026

• Invited Review • Previous Articles Next Articles

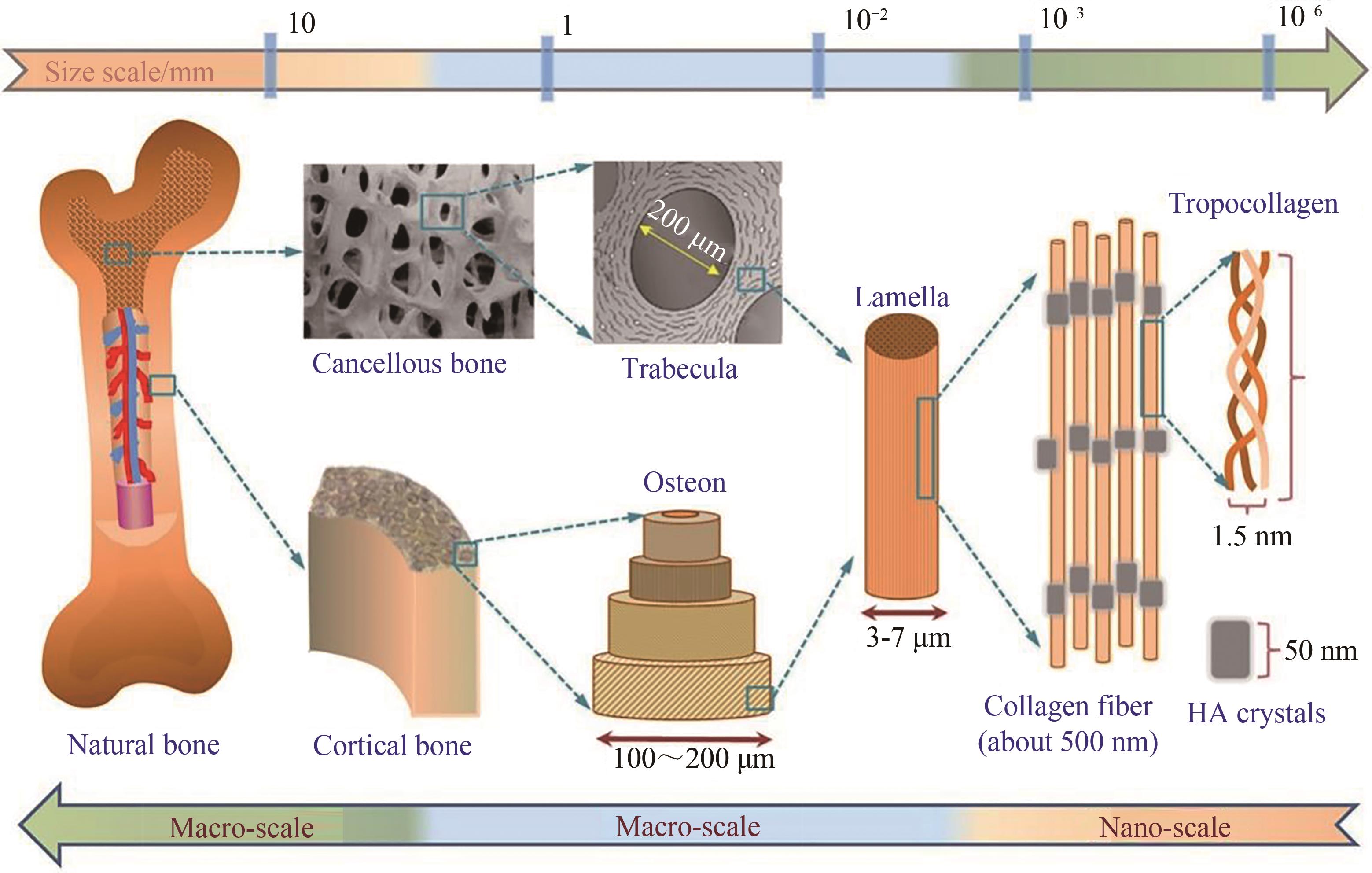

Research progress on the construction of three-dimensional porous structure of bone tissue repair scaffolds based on silk fibroin materials

SHAO Yunfei1, WANG Hui1, ZHU Yiran1, WANG Shuchun1, JIANG Yulin1, HU Jianchen1, WANG Jing2, ZHANG Keqin1

- 1.Laboratory National Engineering Laboratory for Modern Silk (Suzhou),College of Textile and Clothing Engineering,Soochow University,Suzhou 215123,Jiangsu,China

2.School of Mechanical Engineering,Xi'an Jiaotong University,Xi'an 710049,Shaanxi,China

-

Received:2022-04-28Revised:2022-07-12Online:2022-09-08Published:2022-08-31 -

Contact:WANG Hui, ZHANG Keqin

基于丝素蛋白材料构建骨组织修复支架的三维多孔结构体系的研究进展

邵云菲1, 王卉1, 朱怡然1, 王树春1, 姜雨淋1, 胡建臣1, 王晶2, 张克勤1

- 1.苏州大学纺织与服装工程学院,现代丝绸国家工程实验室(苏州),纺织行业丝绸功能材料与技术重点实验室,江苏 苏州 215123

2.西安交通大学机械工程学院,陕西 西安 710049

-

通讯作者:王卉,张克勤 -

作者简介:邵云菲 (1995—),女,博士研究生。研究方向为丝素蛋白基骨组织工程支架制备及生物学应用。E-mail:361503687@qq.com王卉 (1980—),女,副教授,硕士生导师。研究方向:向自然学习,利用受生物启发的合成策略和仿生原理设计构建具有仿生微/纳多级结构的生物材料,通过研究材料表/界面拓扑结构与功能的内在联系,探索仿生结构材料诱导组织再生修复的机制,开发理想的组织再生材料。E-mail:whui@suda.edu.cn张克勤 (1972—),男,教授,博士生导师。研究方向:长期从事软物质与生物物理、生物与多功能复合纤维材料研究,同时进行功能纤维(中空纤维,结构色纤维和纳米复合纤维)的成果转化。E-mail:kqzhang@suda.edu.cn -

基金资助:国家重点研发计划(2017YFA0204600);国家自然科学基金面上项目(51873134);江苏省自然科学基金面上项目(BK20211317);江苏省丝绸工程重点实验室开放课题(KJS1833);南通市科技计划(JC2021043)

CLC Number:

Cite this article

SHAO Yunfei, WANG Hui, ZHU Yiran, WANG Shuchun, JIANG Yulin, HU Jianchen, WANG Jing, ZHANG Keqin. Research progress on the construction of three-dimensional porous structure of bone tissue repair scaffolds based on silk fibroin materials[J]. Synthetic Biology Journal, 2022, 3(4): 795-809.

邵云菲, 王卉, 朱怡然, 王树春, 姜雨淋, 胡建臣, 王晶, 张克勤. 基于丝素蛋白材料构建骨组织修复支架的三维多孔结构体系的研究进展[J]. 合成生物学, 2022, 3(4): 795-809.

share this article

Add to citation manager EndNote|Ris|BibTeX

URL: https://synbioj.cip.com.cn/EN/10.12211/2096-8280.2022-026

Fig. 3 Schematic diagram of the formation process of Ca2+ induced multi-level porous structure Ca/SFS scaffolds, SEM micrographs of Ca/SFS scaffolds and proliferation and osteogenic differentiation of growing cells on surface [58]

Fig. 4 Schematic diagram of SF scaffold prepared by inverse opal method, scaffold structure and pore size distribution, calcium content measured after 6 weeks in culture for salt-leached (black columns) and inverse opal (gray columns) scaffolds [68,71]

| 制备方法 | 调控参数 | 孔隙特征 | 可控性 | 优缺点 | 参考 文献 |

|---|---|---|---|---|---|

| 冷冻干燥 | SF浓度、二级结构、混合溶液成分、降温速度和温度 | 随机(各向同性)、线性(各向异性),通常在50~250 μm | 简便,不太可控 | 有利于生物活性分子结合;孔径较小,互连性差 | [ |

| 粒子沥滤 | 致孔剂的形状和数量 | 孔隙与致孔剂颗粒形貌一致,通常在200~1000 μm | 较简单,一定的可控性 | 孔隙率高;支架厚度受到限制 | [ |

| 生物3D打印 | 打印模型设计 | 多为十字网格形貌,间距调节范围广,可在200 μm~1 mm | 快速成型,精确可控 | 满足不同形状骨缺损修复;仪器昂贵,墨水难制 | [ |

| 复合制造技术 | 各工艺相关参数 | 宏观-介观-微观多尺度、 多层级结构 | 多尺度,较高的可控性 | 获得更多层级支架;各类技术结合较难操作 | [ |

Tab. 1 Pore structure regulation of SF-based 3D bone tissue repair scaffolds by different preparation methods

| 制备方法 | 调控参数 | 孔隙特征 | 可控性 | 优缺点 | 参考 文献 |

|---|---|---|---|---|---|

| 冷冻干燥 | SF浓度、二级结构、混合溶液成分、降温速度和温度 | 随机(各向同性)、线性(各向异性),通常在50~250 μm | 简便,不太可控 | 有利于生物活性分子结合;孔径较小,互连性差 | [ |

| 粒子沥滤 | 致孔剂的形状和数量 | 孔隙与致孔剂颗粒形貌一致,通常在200~1000 μm | 较简单,一定的可控性 | 孔隙率高;支架厚度受到限制 | [ |

| 生物3D打印 | 打印模型设计 | 多为十字网格形貌,间距调节范围广,可在200 μm~1 mm | 快速成型,精确可控 | 满足不同形状骨缺损修复;仪器昂贵,墨水难制 | [ |

| 复合制造技术 | 各工艺相关参数 | 宏观-介观-微观多尺度、 多层级结构 | 多尺度,较高的可控性 | 获得更多层级支架;各类技术结合较难操作 | [ |

| 1 | MÜLLER R. Hierarchical microimaging of bone structure and function[J]. Nature Reviews Rheumatology, 2009, 5(7): 373-381. |

| 2 | MA H S, FENG C, CHANG J, et al. 3D-printed bioceramic scaffolds: from bone tissue engineering to tumor therapy[J]. Acta Biomaterialia, 2018, 79: 37-59. |

| 3 | MANDAL B B, GRINBERG A, GIL E S, et al. High-strength silk protein scaffolds for bone repair[J]. Proceedings of the National Academy of Sciences of the United States of America, 2012, 109(20): 7699-7704. |

| 4 | MOHAMMADI H, SEPANTAFAR M, MUHAMAD N, et al. How does scaffold porosity conduct bone tissue regeneration? [J]. Advanced Engineering Materials, 2021, 23(10): 2100463. |

| 5 | CHOCHOLATA P, KULDA V, BABUSKA V. Fabrication of scaffolds for bone-tissue regeneration[J]. Materials, 2019, 12(4): 568. |

| 6 | NEUBAUER V J, DÖBL A, SCHEIBEL T. Silk-based materials for hard tissue engineering[J]. Materials, 2021, 14(3): 674. |

| 7 | SOUNDARYA S P, MENON A H, CHANDRAN S V, et al. Bone tissue engineering: scaffold preparation using chitosan and other biomaterials with different design and fabrication techniques[J]. International Journal of Biological Macromolecules, 2018, 119: 1228-1239. |

| 8 | SHAO Y F, QING X C, PENG Y Z, et al. Enhancement of mechanical and biological performance on hydroxyapatite/silk fibroin scaffolds facilitated by microwave-assisted mineralization strategy[J]. Colloids and Surfaces B: Biointerfaces, 2021, 197: 111401. |

| 9 | YANG Y, WANG H, ZHU J C, et al. Silk-fibroin-assisted cathodic electrolytic deposition of calcium phosphate for biomedical applications[J]. ACS Biomaterials Science & Engineering, 2019, 5(9): 4302-4310. |

| 10 | NIKOLOVA M P, CHAVALI M S. Recent advances in biomaterials for 3D scaffolds: a review[J]. Bioactive Materials, 2019, 4: 271-292. |

| 11 | RATHEESH G, VENUGOPAL J R, CHINAPPAN A, et al. 3D fabrication of polymeric scaffolds for regenerative therapy[J]. ACS Biomaterials Science & Engineering, 2017, 3(7): 1175-1194. |

| 12 | BURG K J L, PORTER S, KELLAM J F. Biomaterial developments for bone tissue engineering[J]. Biomaterials, 2000, 21(23): 2347-2359. |

| 13 | KASHTE S, JAISWAL A K, KADAM S. Artificial bone via bone tissue engineering: current scenario and challenges[J]. Tissue Engineering and Regenerative Medicine, 2017, 14(1): 1-14. |

| 14 | LIANG W Q, DONG Y Q, SHEN H L, et al. Materials science and design principles of therapeutic materials in orthopedic and bone tissue engineering[J]. Polymers for Advanced Technologies, 2021, 32(12): 4573-4586. |

| 15 | KHOSROPANAH M H, VAGHASLOO M A, SHAKIBAEI M, et al. Biomedical applications of silkworm (Bombyx mori) proteins in regenerative medicine (a narrative review)[J]. Journal of Tissue Engineering and Regenerative Medicine, 2022, 16(2): 91-109. |

| 16 | NGUYEN T P, NGUYEN Q V, NGUYEN V H, et al. Silk fibroin-based biomaterials for biomedical applications: a review[J]. Polymers, 2019, 11(12): 1933. |

| 17 | BABAIE E, BHADURI S B. Fabrication aspects of porous biomaterials in orthopedic applications: a review[J]. ACS Biomaterials Science & Engineering, 2018, 4(1): 1-39. |

| 18 | MBUNDI L, GONZÁLEZ-PÉREZ M, GONZÁLEZ-PÉREZ F, et al. Trends in the development of tailored elastin-like recombinamer-based porous biomaterials for soft and hard tissue applications [J]. Frontiers in Materials, 2021, 7: 601795. |

| 19 | SUN W Z, GREGORY D A, TOMEH M A, et al. Silk fibroin as a functional biomaterial for tissue engineering[J]. International Journal of Molecular Sciences, 2021, 22(3): 1499. |

| 20 | REZNIKOV N, SHAHAR R, WEINER S. Bone hierarchical structure in three dimensions[J]. Acta Biomaterialia, 2014, 10(9): 3815-3826. |

| 21 | DING Z Z, CHENG W N, MIA M S, et al. Silk biomaterials for bone tissue engineering[J]. Macromolecular Bioscience, 2021, 21(8): e2100153. |

| 22 | WU S L, LIU X M, YEUNG K W K, et al. Biomimetic porous scaffolds for bone tissue engineering[J]. Materials Science and Engineering: R: Reports, 2014, 80: 1-36. |

| 23 | GAO C D, PENG S P, FENG P, et al. Bone biomaterials and interactions with stem cells[J]. Bone Research, 2017, 5: 17059. |

| 24 | CHEN H, HAN Q, WANG C Y, et al. Porous scaffold design for additive manufacturing in orthopedics: a review[J]. Frontiers in Bioengineering and Biotechnology, 2020, 8: 609. |

| 25 | ZHANG M, LIN R C, WANG X, et al. 3D printing of Haversian bone-mimicking scaffolds for multicellular delivery in bone regeneration[J]. Science Advances, 2020, 6(12): eaaz6725. |

| 26 | KARAGEORGIOU V, KAPLAN D. Porosity of 3D biomaterial scaffolds and osteogenesis[J]. Biomaterials, 2005, 26(27): 5474-5491. |

| 27 | GÓMEZ S, VLAD M D, LÓPEZ J, et al. Design and properties of 3D scaffolds for bone tissue engineering[J]. Acta Biomaterialia, 2016, 42: 341-350. |

| 28 | ZHANG D W, WU X W, CHEN J D, et al. The development of collagen based composite scaffolds for bone regeneration[J]. Bioactive Materials, 2017, 3(1): 129-138. |

| 29 | PORTER J R, RUCKH T T, POPAT K C. Bone tissue engineering: a review in bone biomimetics and drug delivery strategies[J]. Biotechnology Progress, 2009, 25(6): 1539-1560. |

| 30 | LI J J, EBIED M, XU J, et al. Current approaches to bone tissue engineering: the interface between biology and engineering[J]. Advanced Healthcare Materials, 2018, 7(6): e1701061. |

| 31 | WANG C Y, XIA K L, ZHANG Y Y, et al. Silk-based advanced materials for soft electronics[J]. Accounts of Chemical Research, 2019, 52(10): 2916-2927. |

| 32 | MELKE J, MIDHA S, GHOSH S, et al. Silk fibroin as biomaterial for bone tissue engineering[J]. Acta Biomaterialia, 2016, 31: 1-16. |

| 33 | GUO C C, LI C M, MU X, et al. Engineering silk materials: from natural spinning to artificial processing[J]. Applied Physics Reviews, 2020, 7(1): 011313. |

| 34 | HOLLAND C, NUMATA K, RNJAK-KOVACINA J, et al. The biomedical use of silk: past, present, future[J]. Advanced Healthcare Materials, 2019, 8(1): e1800465. |

| 35 | ALTMAN G H, DIAZ F, JAKUBA C, et al. Silk-based biomaterials[J]. Biomaterials, 2003, 24(3): 401-416. |

| 36 | LU S Z, WANG X Q, LU Q, et al. Insoluble and flexible silk films containing glycerol[J]. Biomacromolecules, 2010, 11(1): 143-150. |

| 37 | HU X, SHMELEV K, SUN L, et al. Regulation of silk material structure by temperature-controlled water vapor annealing[J]. Biomacromolecules, 2011, 12(5): 1686-1696. |

| 38 | SARTIKA D, WANG C H, WANG D H, et al. Human adipose-derived mesenchymal stem cells-incorporated silk fibroin as a potential bio-scaffold in guiding bone regeneration[J]. Polymers, 2020, 12(4): 853. |

| 39 | LI M Z, OGISO M, MINOURA N. Enzymatic degradation behavior of porous silk fibroin sheets[J]. Biomaterials, 2003, 24(2): 357-365. |

| 40 | ZHAO C X, WU X F, ZHANG Q, et al. Enzymatic degradation of Antheraea pernyi silk fibroin 3D scaffolds and fibers[J]. International Journal of Biological Macromolecules, 2011, 48(2): 249-255. |

| 41 | CAO Y, WANG B C. Biodegradation of silk biomaterials[J]. International Journal of Molecular Sciences, 2009, 10(4): 1514-1524. |

| 42 | WANG Y Z, RUDYM D D, WALSH A, et al. In vivo degradation of three-dimensional silk fibroin scaffolds[J]. Biomaterials, 2008, 29(24/25): 3415-3428. |

| 43 | WANG Q, CHU Y Y, HE J X, et al. A graded graphene oxide-hydroxyapatite/silk fibroin biomimetic scaffold for bone tissue engineering[J]. Materials Science and Engineering: C, 2017, 80: 232-242. |

| 44 | FAROKHI M, MOTTAGHITALAB F, SAMANI S, et al. Silk fibroin/hydroxyapatite composites for bone tissue engineering[J]. Biotechnology Advances, 2018, 36(1): 68-91. |

| 45 | WU C T, ZHANG Y F, ZHOU Y H, et al. A comparative study of mesoporous glass/silk and non-mesoporous glass/silk scaffolds: physiochemistry and in vivo osteogenesis[J]. Acta Biomaterialia, 2011, 7(5): 2229-2236. |

| 46 | KASOJU N, BORA U. Silk fibroin in tissue engineering[J]. Advanced Healthcare Materials, 2012, 1(4): 393-412. |

| 47 | BAI S M, HAN H Y, HUANG X W, et al. Silk scaffolds with tunable mechanical capability for cell differentiation[J]. Acta Biomaterialia, 2015, 20: 22-31. |

| 48 | LUJERDEAN C, BACI G M, CUCU A A, et al. The contribution of silk fibroin in biomedical engineering[J]. Insects, 2022, 13(3): 286. |

| 49 | MEINEL L, FAJARDO R, HOFMANN S, et al. Silk implants for the healing of critical size bone defects[J]. Bone, 2005, 37(5): 688-698. |

| 50 | ROCKWOOD D N, PREDA R C, YÜCEL T, et al. Materials fabrication from Bombyx mori silk fibroin[J]. Nature Protocols, 2011, 6(10): 1612-1631. |

| 51 | COLLINS M N, REN G, YOUNG K, et al. Scaffold fabrication technologies and structure/function properties in bone tissue engineering[J]. Advanced Functional Materials, 2021, 31(21): 2010609. |

| 52 | CHENG N, DAI J, CHENG X R, et al. Porous CaP/silk composite scaffolds to repair femur defects in an osteoporotic model[J]. Journal of Materials Science Materials in Medicine, 2013, 24(8): 1963-1975. |

| 53 | 于潇, 马勇, 郭杨, 等. 丝素支架应用于骨组织工程的研究进展[J]. 中国中医骨伤科杂志, 2021, 29(5): 84-88. |

| YU X, MA Y, GUO Y, et al. Research progress of silk fibroin scaffolds used in bone tissue engineering[J]. Chinese Journal of Traditional Medical Traumatology & Orthopedics, 2021, 29(5): 84-88. | |

| 54 | CORREIA C, BHUMIRATANA S, YAN L P, et al. Development of silk-based scaffolds for tissue engineering of bone from human adipose-derived stem cells[J]. Acta Biomaterialia, 2012, 8(7): 2483-2492. |

| 55 | TONG S, XU D P, LIU Z M, et al. Construction and in vitro characterization of three-dimensional silk fibroinchitosan scaffolds[J]. Dental Materials Journal, 2015, 34(4): 475-484. |

| 56 | YAN L P, SALGADO A J, OLIVEIRA J M, et al. De novo bone formation on macro/microporous silk and silk/nano-sized calcium phosphate scaffolds[J]. Journal of Bioactive and Compatible Polymers, 2013, 28(5): 439-452. |

| 57 | MANDAL B B, KUNDU S C. Cell proliferation and migration in silk fibroin 3D scaffolds[J]. Biomaterials, 2009, 30(15): 2956-2965. |

| 58 | WANG H, LIU X Y, CHUAH Y J, et al. Design and engineering of silk fibroin scaffolds with biomimetic hierarchical structures[J]. Chemical Communications, 2013, 49(14): 1431-1433. |

| 59 | BICHO D, CANADAS R F, GONÇALVES C, et al. Porous aligned ZnSr-doped β-TCP/silk fibroin scaffolds using ice-templating method for bone tissue engineering applications[J]. Journal of Biomaterials Science Polymer Edition, 2021, 32(15): 1966-1982. |

| 60 | 张伟忠, 李磊, 何贺, 等. 纳米纤维大孔支架制备技术在骨组织工程研究中的应用与意义[J]. 中国组织工程研究, 2020, 24(28): 4437-4444. |

| ZHANG W Z, LI L, HE H, et al. Application and significance of nanofibrous macroporous scaffold preparation technology for bone tissue engineering[J]. Chinese Journal of Tissue Engineering Research, 2020, 24(28): 4437-4444. | |

| 61 | NAZAROV R, JIN H J, KAPLAN D L. Porous 3-D scaffolds from regenerated silk fibroin[J]. Biomacromolecules, 2004, 5(3): 718-726. |

| 62 | RAJKHOWA R, GIL E S, KLUGE J, et al. Reinforcing silk scaffolds with silk particles[J]. Macromolecular Bioscience, 2010, 10(6): 599-611. |

| 63 | MANIGLIO D, BONANI W, MIGLIARESI C, et al. Silk fibroin porous scaffolds by N2O foaming[J]. Journal of Biomaterials Science, Polymer Edition, 2018, 29(5): 491-506. |

| 64 | ZENG C, YANG Q, ZHU M F, et al. Silk fibroin porous scaffolds for nucleus pulposus tissue engineering[J]. Materials Science and Engineering: C, 2014, 37: 232-240. |

| 65 | PARK H J, LEE O J, LEE M C, et al. Fabrication of 3D porous silk scaffolds by particulate (salt/sucrose) leaching for bone tissue reconstruction[J]. International Journal of Biological Macromolecules, 2015, 78: 215-223. |

| 66 | 廖银琳, 王卉, 张克勤. 医用组织工程多孔丝素支架制备方法的进展[J]. 印染, 2012, 38(10): 48-53. |

| LIAO Y L, WANG H, ZHANG K Q. Advances in preparation of porous silk fibroin scaffolds for medical tissue engineering[J]. Dyeing & Finishing, 2012, 38(10): 48-53. | |

| 67 | 宋颖, 邓久鹏, 张炜. 骨组织工程多孔支架制备方法的研究进展[J]. 生物医学工程与临床, 2021, 25(2): 246-250. |

| SONG Y, DENG J P, ZHANG W. Progress in preparation methods of porous scaffolds for bone tissue engineering[J]. Biomedical Engineering and Clinical Medicine, 2021, 25(2): 246-250. | |

| 68 | ZHANG Y S, ZHU C L, XIA Y N. Inverse opal scaffolds and their biomedical applications[J]. Advanced Materials, 2017, 29(33): 1701115. |

| 69 | ZHU C, PONGKITWITOON S, QIU J, et al. Design and fabrication of a hierarchically structured scaffold for tendon-to-bone repair[J]. Advanced Materials, 2018, 30(16): e1707306. |

| 70 | ZHU C, QIU J, PONGKITWITOON S, et al. Inverse opal scaffolds with gradations in mineral content for spatial control of osteogenesis[J]. Advanced Materials, 2018, 30(29): e1706706. |

| 71 | SOMMER M R, VETSCH J R, LEEMANN J, et al. Silk fibroin scaffolds with inverse opal structure for bone tissue engineering[J]. Journal of Biomedical Materials Research Part B, Applied Biomaterials, 2017, 105(7): 2074-2084. |

| 72 | DONDERWINKEL I, VAN HEST J C M, CAMERON N R. Bio-inks for 3D bioprinting: recent advances and future prospects[J]. Polymer Chemistry, 2017, 8(31): 4451-4471. |

| 73 | RODRIGUEZ M J, DIXON T A, COHEN E, et al. 3D freeform printing of silk fibroin[J]. Acta Biomaterialia, 2018, 71: 379-387. |

| 74 | KIM S H, HONG H, AJITERU O, et al. 3D bioprinted silk fibroin hydrogels for tissue engineering[J]. Nature Protocols, 2021, 16(12): 5484-5532. |

| 75 | HUANG Y, ZHANG X F, GAO G, et al. 3D bioprinting and the current applications in tissue engineering[J]. Biotechnology Journal, 2017, 12(8): 1600734. |

| 76 | DU X Y, WEI D X, HUANG L, et al. 3D printing of mesoporous bioactive glass/silk fibroin composite scaffolds for bone tissue engineering[J]. Materials Science and Engineering: C, 2019, 103: 109731. |

| 77 | LEE H, SHIN D, SHIN S, et al. Effect of gelatin on dimensional stability of silk fibroin hydrogel structures fabricated by digital light processing 3D printing[J]. Journal of Industrial and Engineering Chemistry, 2020, 89: 119-127. |

| 78 | SCHWAB A, LEVATO R, D'ESTE M, et al. Printability and shape fidelity of bioinks in 3D bioprinting[J]. Chemical Reviews, 2020, 120(19): 11028-11055. |

| 79 | ZHENG Z Z, WU J B, LIU M, et al. 3D bioprinting of self-standing silk-based bioink[J]. Advanced Healthcare Materials, 2018, 7(6): e1701026. |

| 80 | KIM S H, YEON Y K, LEE J M, et al. Precisely printable and biocompatible silk fibroin bioink for digital light processing 3D printing[J]. Nature Communications, 2018, 9: 1620. |

| 81 | WANG Q, HAN G, YAN S, et al. 3D printing of silk fibroin for biomedical applications[J]. Materials, 2019, 12(3): E504. |

| 82 | 姜雨淋, 王卉, 张克勤. 生物3D打印用丝素蛋白基凝胶墨水的研究进展[J]. 纺织学报, 2021, 42(11): 1-8. |

| JIANG Y L, WANG H, ZHANG K Q. Research progress of silk fibroin-based hydrogel bioinks for 3D bio-printing[J]. Journal of Textile Research, 2021, 42(11): 1-8. | |

| 83 | WEI L, WU S H, KUSS M, et al. 3D printing of silk fibroin-based hybrid scaffold treated with platelet rich plasma for bone tissue engineering[J]. Bioactive Materials, 2019, 4: 256-260. |

| 84 | VYAS C, ZHANG J, ØVREBØ Ø, et al. 3D printing of silk microparticle reinforced polycaprolactone scaffolds for tissue engineering applications[J]. Materials Science and Engineering: C, 2021, 118: 111433. |

| 85 | APPLEGATE M B, PARTLOW B P, COBURN J, et al. Photocrosslinking of silk fibroin using riboflavin for ocular prostheses[J]. Advanced Materials, 2016, 28(12): 2417-2420. |

| 86 | KURLAND N E, DEY T, KUNDU S C, et al. Precise patterning of silk microstructures using photolithography[J]. Advanced Materials, 2013, 25(43): 6207-6212. |

| 87 | PEI B Y, WANG Z K, NIE J Y, et al. Highly mineralized chitosan-based material with large size, gradient mineral distribution and hierarchical structure[J]. Carbohydrate Polymers, 2019, 208: 336-344. |

| 88 | ROOHANI-ESFAHANI S I, LU Z F, Novel ZREIQAT H., simple and reproducible method for preparation of composite hierarchal porous structure scaffolds[J]. Materials Letters, 2011, 65(17/18): 2578-2581. |

| 89 | CHISCA S, MUSTEATA V E, SOUGRAT R, et al. Artificial 3D hierarchical and isotropic porous polymeric materials[J]. Science Advances, 2018, 4(5): eaat0713. |

| 90 | DU L L, LI W, JIANG Z Y, et al. Hierarchical macro/micro-porous silk fibroin scaffolds for tissue engineering[J]. Materials Letters, 2019, 236: 1-4. |

| 91 | YAN L P, SILVA-CORREIA J, CORREIA C, et al. Bioactive macro/micro porous silk fibroin/nano-sized calcium phosphate scaffolds with potential for bone-tissue-engineering applications[J]. Nanomedicine, 2013, 8(3): 359-378. |

| 92 | 李东, 张振辉, 郑程程, 等. 低温3D打印联合冷冻干燥技术制备组织工程骨支架的研究[J]. 中国修复重建外科杂志, 2016, 30(3): 292-297. |

| LI D, ZHANG Z H, ZHENG C C, et al. Cytocompatibility and preparation of bone tissue engineering scaffold by combining low temperature three dimensional printing and vacuum freeze-drying techniques[J]. Chinese Journal of Reparative and Reconstructive Surgery, 2016, 30(3): 292-297. | |

| 93 | SOMMER M R, SCHAFFNER M, CARNELLI D, et al. 3D printing of hierarchical silk fibroin structures[J]. ACS Applied Materials & Interfaces, 2016, 8(50): 34677-34685. |

| 94 | KARAMAT-ULLAH N, DEMIDOV Y, SCHRAMM M, et al. 3D printing of antibacterial, biocompatible, and biomimetic hybrid aerogel-based scaffolds with hierarchical porosities via integrating antibacterial peptide-modified silk fibroin with silica nanostructure[J]. ACS Biomaterials Science & Engineering, 2021, 7(9): 4545-4556. |

| 95 | LIU A P, APPEL E A, ASHBY P D, et al. The living interface between synthetic biology and biomaterial design[J]. Nature Materials, 2022, 21(4): 390-397. |

| 96 | KELWICK R J R, WEBB A J, FREEMONT P S. Biological materials: the next frontier for cell-free synthetic biology[J]. Frontiers in Bioengineering and Biotechnology, 2020, 8: 399. |

| 97 | TANG T C, AN B L, HUANG Y Y, et al. Materials design by synthetic biology[J]. Nature Reviews Materials, 2021, 6(4): 332-350. |

| 98 | KUWANA Y, SEZUTSU H, NAKAJIMA K I, et al. High-toughness silk produced by a transgenic silkworm expressing spider (Araneus ventricosus) dragline silk protein[J]. PLoS One, 2014, 9(8): e105325. |

| 99 | XU J, DONG Q L, YU Y, et al. Mass spider silk production through targeted gene replacement in Bombyx mori [J]. Proceedings of the National Academy of Sciences of the United States of America, 2018, 115(35): 8757-8762. |

| 100 | YANG Y X, QIAN Z G, ZHONG J J, et al. Hyper-production of large proteins of spider dragline silk MaSp2 by Escherichia coli via synthetic biology approacb[J]. Process Biochemistry, 2016, 51: 484-490. |

| [1] | Naicai ZHONG, Yuan CHEN, Wenfeng PAN, Xiaofeng SU, Jingwen LIAO, Jinyi ZHONG. Application progress of plasma microbial breeding technology in biofabrication [J]. Synthetic Biology Journal, 2025, (): 1-17. |

| [2] | Shuhan HUANG, He MA, Yunzi LUO. Research progress on biosynthesis of salidroside [J]. Synthetic Biology Journal, 2025, (): 1-16. |

| [3] | REN Jiawei, ZHANG Jinpeng, XU Guoqiang, ZHANG Xiaomei, XU Zhenghong, ZHANG Xiaojuan. Effect of terminators on the downstream transcript unit with gene expression in Escherichiacoli [J]. Synthetic Biology Journal, 2025, 6(1): 213-227. |

| [4] | XU Huaisheng, SHI Xiaolong, LIU Xiaoguang, XU Miaomiao. Key technologies for DNA storage: encoding, error correction, random access, and security [J]. Synthetic Biology Journal, 2025, 6(1): 157-176. |

| [5] | Yongzhu LI, Yu CHEN. Advances and Prospects in Genome-Scale Models of Yeast [J]. Synthetic Biology Journal, 2025, (): 1-18. |

| [6] | LI Yifei, CHEN Ai, SUN Junsong, ZHANG Yi-Heng P. Job. Studies on hydrogenases for hydrogen production using in vitro synthetic enzymatic biosystems [J]. Synthetic Biology Journal, 2024, 5(6): 1461-1484. |

| [7] | SHI Ting, SONG Zhan, SONG Shiyi, ZHANG Yi-Heng P. Job. In vitro BioTransformation (ivBT): a new frontier of industrial biomanufacturing [J]. Synthetic Biology Journal, 2024, 5(6): 1437-1460. |

| [8] | LIU Kuanqing, ZHANG Yi-Heng P.Job. Biological degradation and utilization of lignin [J]. Synthetic Biology Journal, 2024, 5(6): 1264-1278. |

| [9] | CHAI Meng, WANG Fengqing, WEI Dongzhi. Synthesis of organic acids from lignocellulose by biotransformation [J]. Synthetic Biology Journal, 2024, 5(6): 1242-1263. |

| [10] | Xinyi GUO, Shuqi GUO, Shuwei LI, Ziyue JIAO, Qiang FEI. Progress in Biological Entity-Material Hybrid System for Low-Carbon Biosynthesis [J]. Synthetic Biology Journal, 2024, (): 1-14. |

| [11] | CHEN Guo-Qiang, TAN Dan. Reprogramming microbial chassis for low-cost bioprodcution of tailor-made polyhydroxyalkanoates [J]. Synthetic Biology Journal, 2024, 5(5): 1211-1226. |

| [12] | ZHENG Haotian, LI Chaofeng, LIU Liangxu, WANG Jiawei, LI Hengrun, NI Jun. Design, optimization and application of synthetic carbon-negative phototrophic community [J]. Synthetic Biology Journal, 2024, 5(5): 1189-1210. |

| [13] | CHENG Xiaolei, LIU Tiangang, TAO Hui. Recent research progress in non-canonical biosynthesis of terpenoids [J]. Synthetic Biology Journal, 2024, 5(5): 1050-1071. |

| [14] | Jinchang LU, Yaokang WU, Xueqin LV, Long LIU, Jian CHEN, Yanfeng LIU. Green biomanufacturing of ceramide sphingolipids [J]. Synthetic Biology Journal, 2024, (): 1-23. |

| [15] | HAN Yizhao, GUO Jia, SHAO Yue. Stem cell-based synthetic development: cellular components, embryonic models, and engineering approaches [J]. Synthetic Biology Journal, 2024, 5(4): 734-753. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||